Nissha FIS's semiconductor-type refrigerant sensor complies with the international IEC60335-2-40 Ed.7 ANNEX LL and the American UL60335-2-40 Ed.4 ANNEX LL, which are quality standards for air conditioning equipment. This sensor was developed as a result of many years of dedicated efforts of Nissha FIS's development team. This article introduces the background of the refrigerant sensor development, including why refrigerant sensors have become necessary, the development history, and the features of the sensor.

- Reasons Why Semiconductor-Type Refrigerant Sensors Have Gained Attention

- Specifications of Semiconductor-Type Refrigerant Sensors Compatible with Both Indoor and Outdoor Units

- Compliance with Japan's Fluorocarbon Emission Control Law, and Expansion into European and U.S. Markets

- Key Development Points for Compliance with IEC and UL Standards

- Challenges Faced in Meeting Mandatory Installation Requirements

- Our Commitment to Further Improve Semiconductor-Type Refrigerant Sensors

- Inquiries about Refrigerant Sensors

- For Those Who Wish to Receive Handout Materials

Reasons Why Semiconductor-Type Refrigerant Sensors Have Gained Attention

Nissha FIS began developing refrigerant sensors for air conditioning equipment around 2017. Prior to that, the demand for refrigerant sensors was relatively low. The mainstream technology for refrigerant sensors was IR (infrared) type, and the semiconductor type, which Nissha FIS specializes in, was used only in limited applications such as leak testers.

The turning point came with the revision of air conditioning equipment standards in Japan. Following amendments to the Fluorocarbon Emission Control Law, it became mandatory to install sensors capable of detecting refrigerant leaks in air conditioning equipment. At that time, semiconductor-type refrigerant sensors emerged as a candidate for the embedded sensors.

For air conditioning equipment manufacturers, who are customers of Nissha FIS, the introduction of refrigerant sensors, which had not been necessary before, represented an additional cost. This led to a demand for sensors that could be implemented with minimal financial burden. The semiconductor-type refrigerant sensors, which are more cost-effective compared to other types such as IR sensors, met this need. Additionally, the fact that semiconductor-type refrigerant sensors were relatively easy to integrate into air conditioning equipment made them even more appealing to customers.

In response to this market need and regulatory shift, Nissha FIS initiated the development of semiconductor-type refrigerant sensors that comply with air conditioning equipment standards.

Specifications of Semiconductor-Type Refrigerant Sensors Compatible with Both Indoor and Outdoor Units

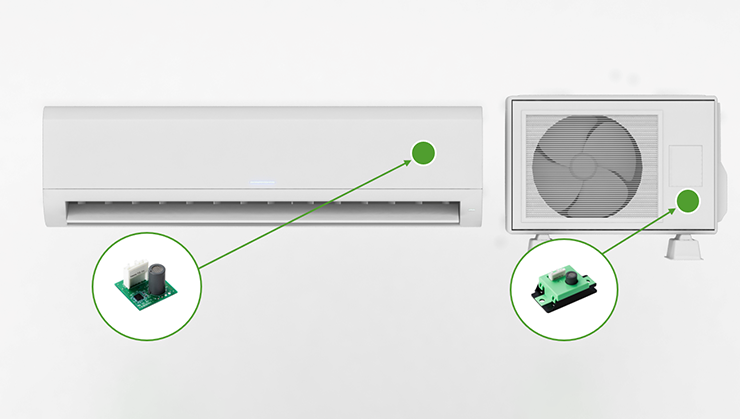

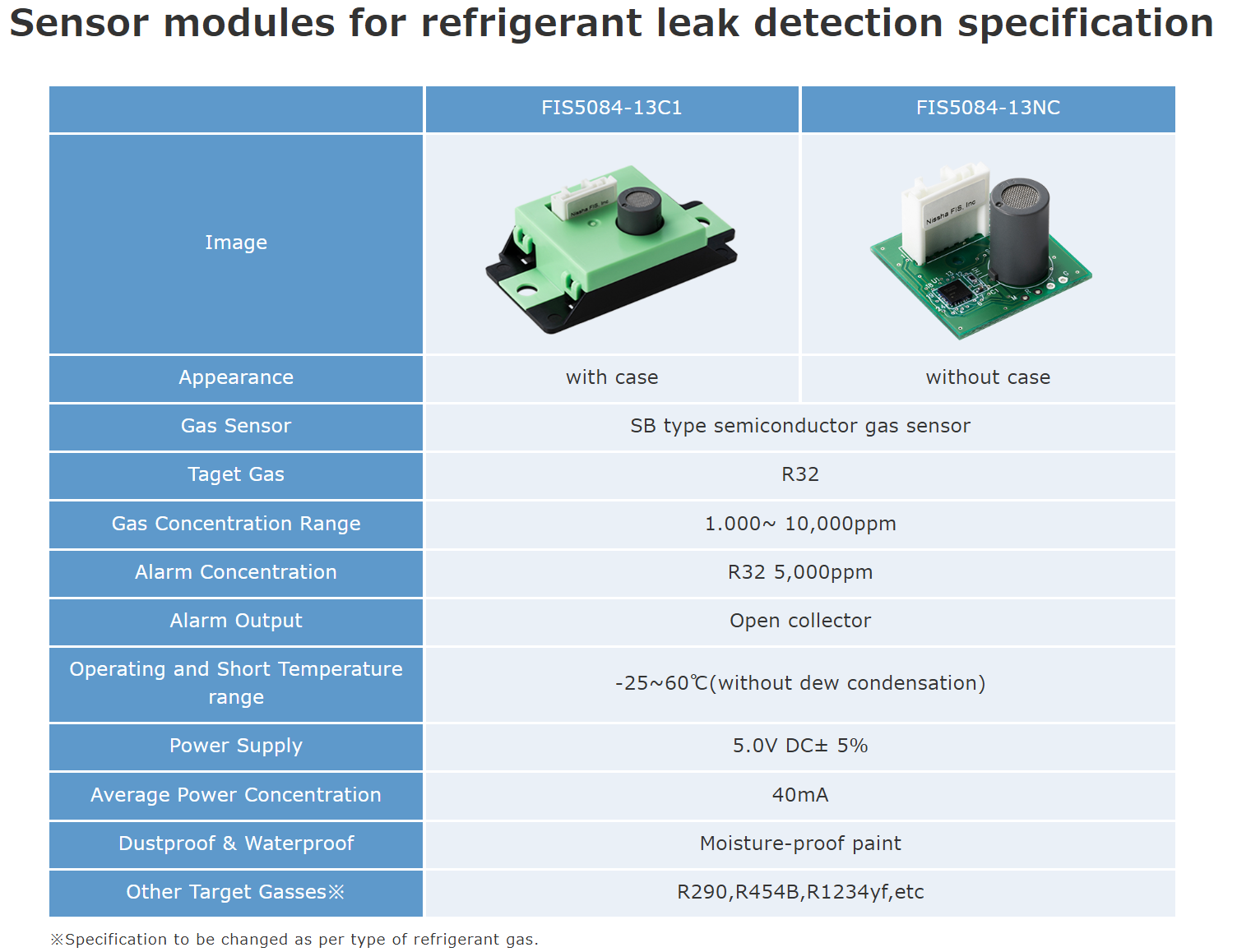

Here, we introduce the basic specifications of Nissha FIS's semiconductor-type refrigerant sensor. This sensor is optimized for integration into air conditioning equipment. Since air conditioning equipment consists of two units, an indoor unit and an outdoor unit, Nissha FIS has developed sensor modules tailored to each. The specifications of the sensors for the indoor and outdoor units are greatly influenced by their respective operating environments. In particular, the outdoor unit is exposed to wind and rain, requiring durability against water and humidity. To address this challenge, Nissha FIS's sensor for outdoor units is enclosed in protective cases to improve moisture resistance.

In addition, since refrigerant leaks must be detected even at very low levels, the sensor's measurement range is set to a low concentration of 1,000 to 10,000 ppm.

Compliance with Japan's Fluorocarbon Emission Control Law, and Expansion into European and U.S. Markets

As mentioned earlier, the response to the standard revision began with compliance with Japan's Fluorocarbon Emission Control Law. So, why was it made mandatory to install refrigerant sensors? The reason lies in the flammability and global warming potential of the alternative fluorocarbons (HFCs) refrigerants commonly used today. HFCs like R32 are mildly flammable gases, and leaks can pose a fire hazard. Additionally, many HFCs have a very high greenhouse effect, meaning that leaks also present a significant environmental issue. As a countermeasure to these challenges, the need to detect refrigerant leaks from air conditioning equipment has increased.

At Nissha FIS, we began by developing sensors that comply with Japan's Fluorocarbon Emission Control Law. The refrigerant sensors we developed were subsequently adopted in products by our domestic customers. Building on this domestic development, we then proceeded to develop sensors for the European and U.S. markets, where the integration of refrigerant sensors has also been regulated.

Key Development Points for Compliance with IEC and UL Standards

Internationally, the quality standards for refrigerant sensors are defined in the air conditioning equipment standard IEC60335-2-40 Ed.7 ANNEX LL, and in the United States, in UL60335-2-40 Ed.4 ANNEX LL. Ensuring measurement accuracy was a crucial point in developing sensors that comply with these standards. In particular, addressing the degradation of sensors when exposed to high concentrations of refrigerant was a key focus of the development.

The durability tests under IEC and UL standards include exposing sensors to high concentrations of refrigerant gas, specifically at concentrations of 1% or higher. Semiconductor-type sensors have the characteristic where the temperature of the sensing element rises significantly when exposed to high concentrations of gas. Therefore, preventing the degradation of the sensing element due to temperature rise was a major challenge.

The strength of Nissha FIS's gas sensors lies in the gas-sensitive materials that we develop in-house. For refrigerant sensors intended for air conditioning equipment, we use gas-sensitive elements that are highly sensitive to fluorocarbons. These elements offer high resolution in detecting fluorocarbon concentrations, enabling more accurate leak detection. As a result, even if the elements degrade due to temperature rise, detection accuracy is more likely to be maintained. Additionally, Nissha FIS has devised the sensor driving method to prevent degradation caused by exposure to high concentrations of fluorocarbons.

Moreover, the IEC and UL standards require that sensors maintain measurement accuracy during repeated testing. Semiconductor-type sensors are designed so that the electrical resistance of the gas-sensitive material changes when it comes into contact with refrigerant. This change in resistance is used to calculate the refrigerant concentration. However, repeated increases and decreases in resistance could alter the state of the gas-sensitive material, raising concerns that resistance may not be measured correctly. In developing refrigerant sensors for air conditioning equipment, we aimed to develop optimal elements that maintain a stable baseline even under repeated resistance fluctuations. As a result, we achieved a level of stability that passes the repeated testing requirements of both IEC and UL standards.

Challenges Faced in Meeting Mandatory Installation Requirements

Refrigerant sensors for air conditioning equipment did not exist until they were mandated by Japan's Fluorocarbon Emission Control Law. In other words, customers had very little knowledge about refrigerant sensors. Therefore, the development of refrigerant sensors had to start with helping customers gain a deeper understanding of these sensors.

Since the product did not exist, there were initially no facilities to evaluate it. We had to start by setting up equipment for performance evaluation. Through continuous dialogue with customers, including setting up evaluation facilities and explaining sensor specifications, the development team-built trust in the new semiconductor-type refrigerant sensor product.

Building on our experience with domestic implementation in Japan, we expanded our development efforts toward the European market, and then to the U.S. market. The expansion into the U.S., in particular, required significant effort. It took time to introduce refrigerant sensor testing equipment to the testing agencies that evaluate UL standards. In some cases, customers were not aware of the mandatory requirement to install refrigerant sensors, which meant we had to put even greater effort into raising awareness of the regulations, more so than in Japan. Nissha FIS's development team stayed in the U.S. for over two months, persistently communicating with UL testing agencies and customer companies. As a result of these efforts, FIS's semiconductor-type refrigerant sensors have been increasingly adopted not only in Japan but also in Europe and North America.

Our Commitment to Further Improve Semiconductor-Type Refrigerant Sensors

Nissha FIS's refrigerant sensors have passed both IEC and UL standards. However, further improvements are still required. This involves addressing the characteristics inherent to semiconductor-type gas sensors.

When exposed to multiple gases simultaneously, the sensing material in semiconductor-type sensors cannot detect each gas individually. This is why selecting a gas-sensitive material that reacts particularly strongly to the desired gas is crucial. Refrigerant sensors are no exception. The next goal is to achieve even more stable refrigerant detection by developing gas-sensitive elements that have improved specificity to the target refrigerant.

Nissha FIS will continue to work on these improvement goals and develop more reliable refrigerant sensors.

Inquiries about Refrigerant Sensors

For inquiries regarding refrigerant sensors, please contact us through this inquiry form.

ContactFor Those Who Wish to Receive Handout Materials

We have prepared a PDF summarizing the specifications of our refrigerant sensors. You can request the document through the download form below. Please take a look.

Download