“connect.nissha.com” is a website that provides information on how Nissha contributes to solving customers' technical and social challenges through various products and services. Please explore the diverse solutions of Nissha offers that 'connect with your business' and 'connect with the world'.

Industrial Materials

-

Design & CMF

Our design department aims to maximize user experience value through CMF design.

-

Mobility Decorative Molded Products

We utilize high-precision printing and molding technologies to achieve diverse shapes and functions, contributing to mobility.

-

IMD & IML

Achieves diverse decorations simultaneously with molding using IMD/IML technology.

-

Transfer Foils

Provides high-quality transfer foils, reproducing various designs.

-

IME (In-mold Electronics)

Integrates electrode films with molding simultaneously using IME technology.

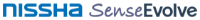

Devices

-

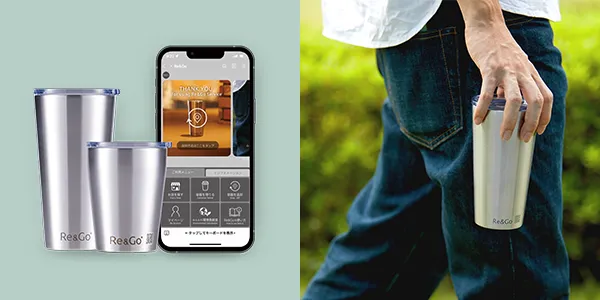

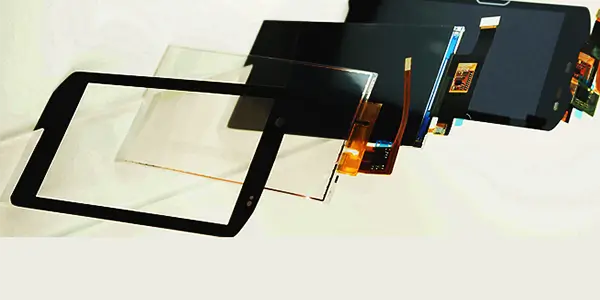

Touch Screens

Our film-based capacitive touch panels boast high reliability and excellent optical properties.

-

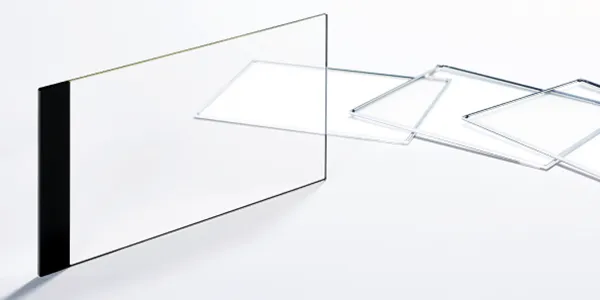

Strain Gauges

Achieves diverse shapes and functions through custom production.

-

Friction and Shear Force Sensors

Measure three-axis forces in real-time.

-

Metasurface Antennas

Improve 5G and 6G communication environments.

-

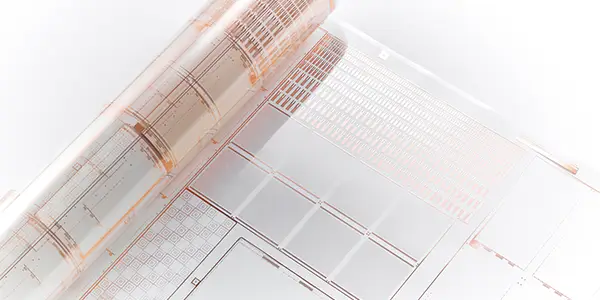

Semi-Additive Process

Forms low-resistance and fine wiring on transparent films using SAP technology

-

Gas Sensing Solutions

Our gas sensors are highly sensitive and accurate, catering to a wide range of applications.

Medical & Healthcare

-

Medical Devices

Provides comprehensive services from design to manufacturing of medical devices based on ISO13485.

-

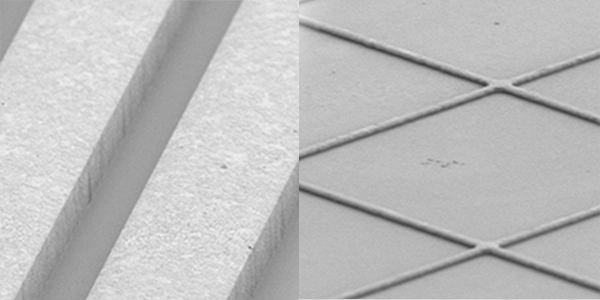

Microneedle Patches

Dissolvable microneedle patches for cosmetics add functional ingredients and are custom-produced.

-

Oral Thin Films

Thin formulations that can be taken without water.

-

Transdermal Patches

Achieves high-quality drug delivery through custom development and manufacturing.

Converting Technologies

-

Patterning / Photolithography

Processes high-precision film elements using roll-to-roll methods.

-

Laminating / Film Element Assembly

Offers film element processing and lamination technology.

-

Coating / Coating

Offers coating technology for thin to thick films.

-

Coating / Vacuum Metalizing

Delivers high-quality metallic films using vacuum deposition technology.

-

Printing / Gravure Printing

Utilizes gravure printing technology for high-precision decoration.

-

Molding / Injection Molding

Provides molding and decoration technologies.

Nissha Co., Ltd. connect.nissha.com

Nissha Co., Ltd. connect.nissha.com