Proven Manufacturing Success

A Million Units in 10 Years

Refrigerant Leak Detection

Refrigerant Gas Sensor Module

Advantages of Our Sensors

- Compliant with global safety standards

- Certified to UL and IEC standards

- Robustness

- Long life time of 15 years / Advanced self-monitoring function

- High detection accuracy / Preventing false detection

- Detection sensitivity within ±20% / Equipped with an interference gas filter

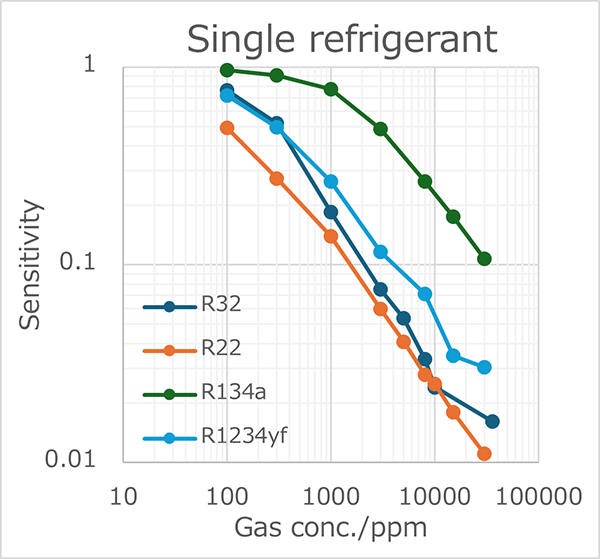

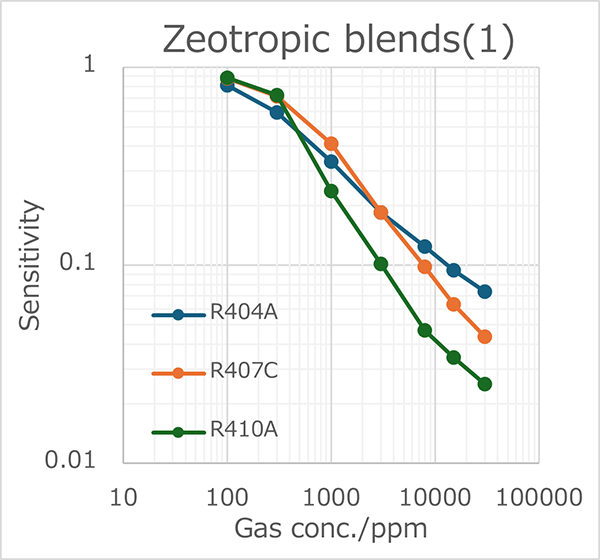

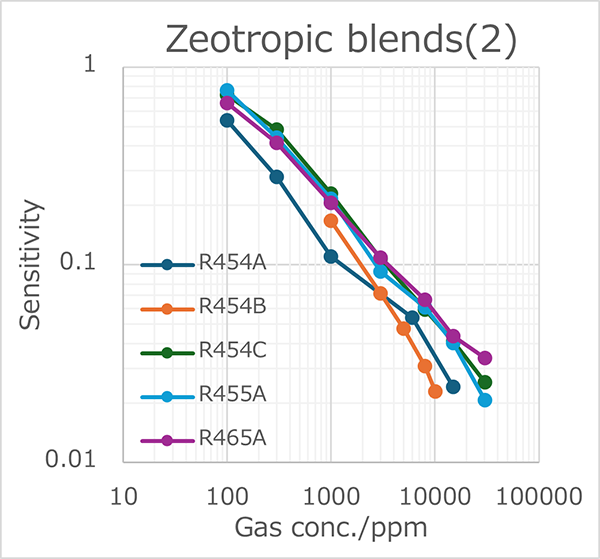

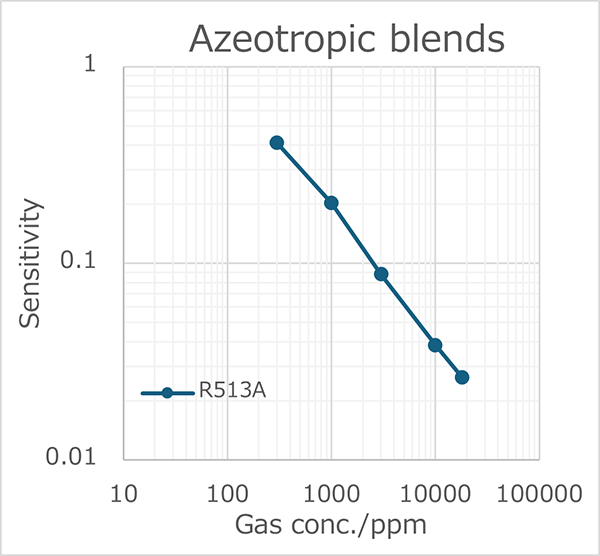

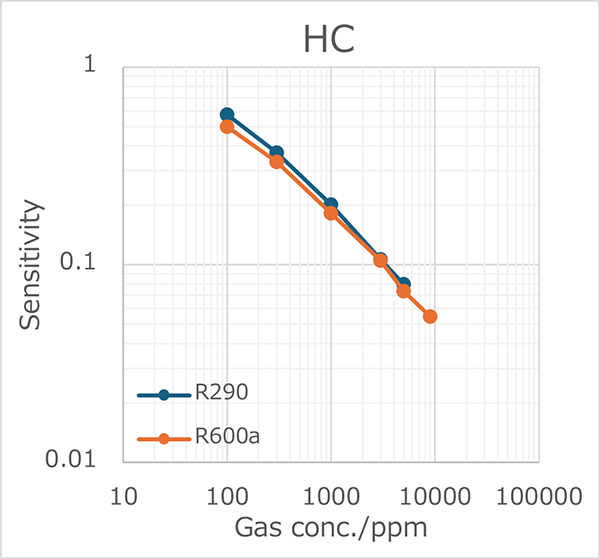

- Compatible with various gases

- Capable of detecting various refrigerants such as A2L and A3

- Easy and flexible setup

- 25-50mm square-sized small sensor / Pre-adjusted using a target gas

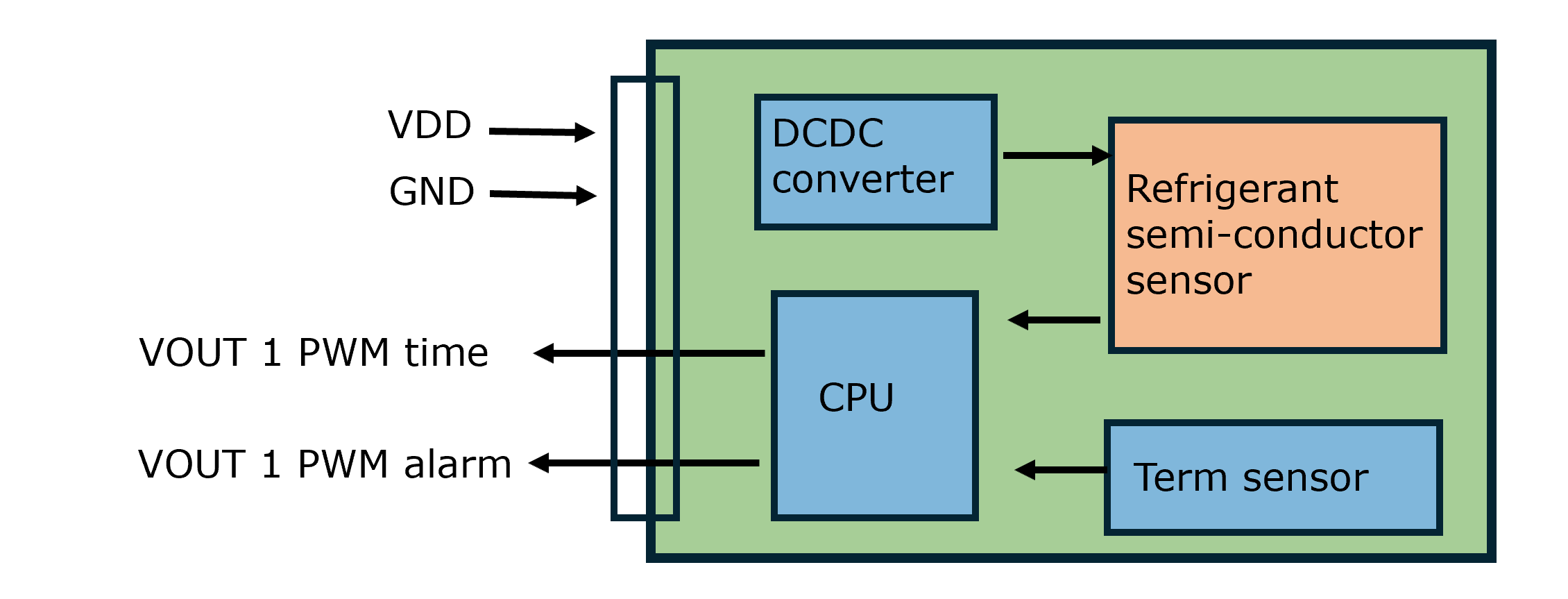

Sensor modules for refrigerant leak detection specification

| FIS5084-13C1 | FIS5084-13NC | |

|---|---|---|

| Image |  |  |

| Appearance | with case | without case |

| Gas Sensor | SB type semiconductor gas sensor | |

| Taget Gas | R32 | |

| Gas Concentration Range | 1.000~ 10,000ppm | |

| Alarm Concentration | R32 5,000ppm | |

| Alarm Output | Open collector | |

| Operating and Short Temperature range | -25~60℃(without dew condensation) | |

| Power Supply | 5.0V DC± 5% | |

| Average Power Concentration | 40mA | |

| Dustproof & Waterproof | Moisture-proof paint | |

| Other Target Gasses※ | R290,R454B,R1234yf,etc | |

※Specification to be changed as per type of refrigerant gas.

Refrigerant Gas Sensor Module

Application

Introducing gas sensor application examples in various fields

Showcase

Data server

VRF air Conditioner

Unitary Air Conditioner

Heat pump