Preparing for North America's New Standard: UL60335-2-40 Edition 4.0

Many of the refrigerants used as heat exchangers in air conditioners, refrigerators, and freezers are greenhouse gases, which are a contributing factor of climate change. There is growing support in the industry for the development and use of refrigerants with lower Global Warming Potential (GWP) values. However, because some novel refrigerants are mildly flammable, ASHRAE has created a new class for refrigerants in its flammability classification system: A2L. In addition, the UL60335-2-40 safety standard has incorporated regulations for the safe functioning of A2L refrigerants beginning with Edition 3.0. The requirements mandate the incorporation of a refrigerant leak detection system. Specifically, the standard requires a notification system that is triggered when a leak is detected, a fan to disburse gases, and a safety shut-off valve to limit the potential scope of a leak. The class of A2L refrigerants includes R32, R1234yf, R454B, and other mixed refrigerants. The upcoming Edition 4.0 will be applied in North America beginning in 2024, and a growing number of regions and products are moving to incorporate the new standard in response to corresponding laws and regulations.

Europe's Latest Standard: IEC60335-2-40 Edition 7.0

Meanwhile, the IEC60335-2-40 standard is already in use in Europe, a leader in environmental regulation initiatives, and the new Edition 7.0 is set to be implemented in the near future. IEC60335-2-40 Edition 7.0 includes provisions which are predicated on the use of refrigerants with lower GWP values, of which R290 is a representative example. While R290 has a low GWP, its flammability classification is A3. Its use is expected to grow in wide a range of applications such as air conditioners and heat pumps.

Nissha FIS is developing a gas sensor module that comply with latest international standards (UL60335-2-40 Edition4.0, IEC60335-2-40 Edition 7.0)

- Excellent responsiveness

- Detects leakage within 15 seconds

- High detection accuracy

- within ±20% of the concentration

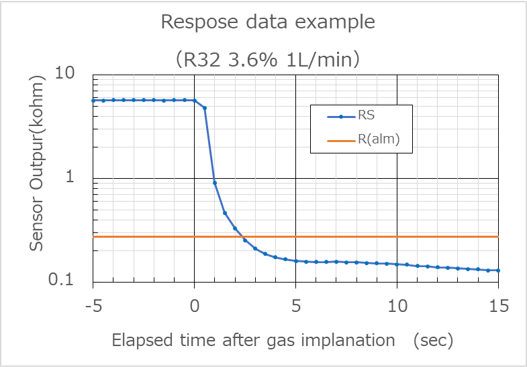

Responsivity Within 15 Seconds

The UL standard specifies that a leak of a mildlly flammable refrigerant must be detected within 10 seconds.

Mildly flammable refrigerants have an increased potential to burn as their concentration increases.

Therefore Refrigerant Sensor need to detect the leak as soon as possible.

Nissha FIS has achieved a response time of less than 10 seconds as required by the standard.

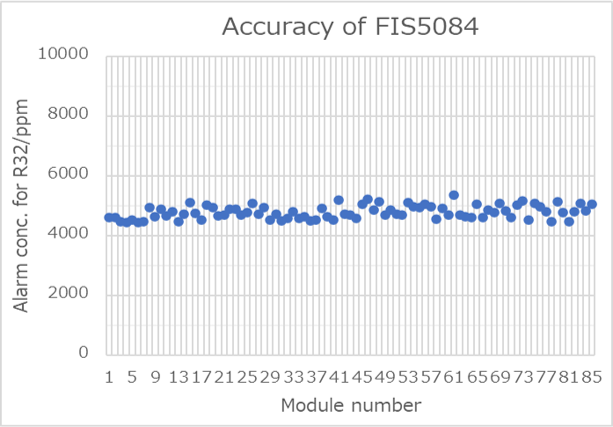

Detection Sensitivity Within ±20%

The latest international standards call for gas concentration detection sensitivity within ±20%.

The test results given on the right show that our semiconductor sensors can meet these sensitivity demands.

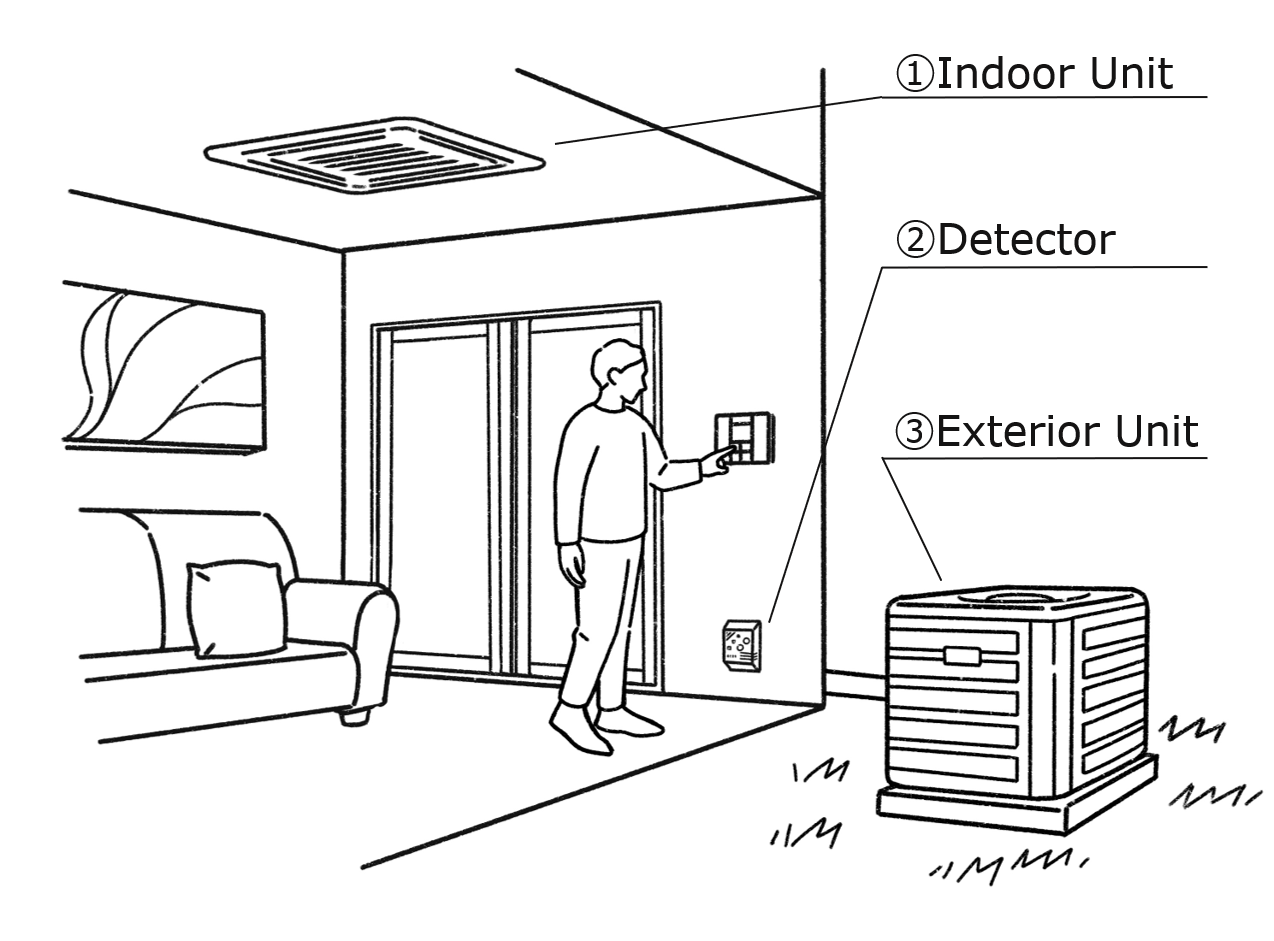

Sensor module mounting position

Suitable place to install the sensor

- Indoor Unit

- Detector at Low position in the room

- Exterior unit in a location isolated by a wall

*Since the specific gravity of refrigerant is heavier than that of air,

it is necessary to install it at a lower position than where there is a possibility of leakage.

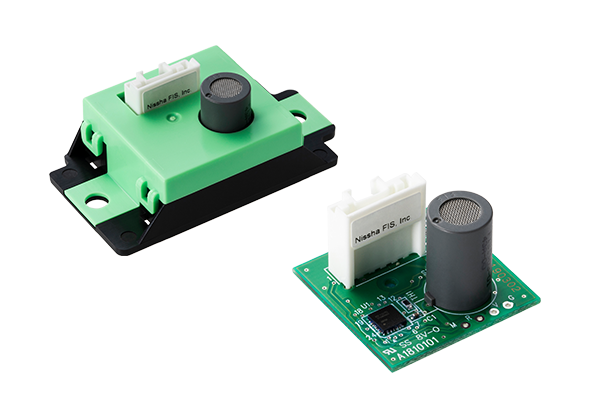

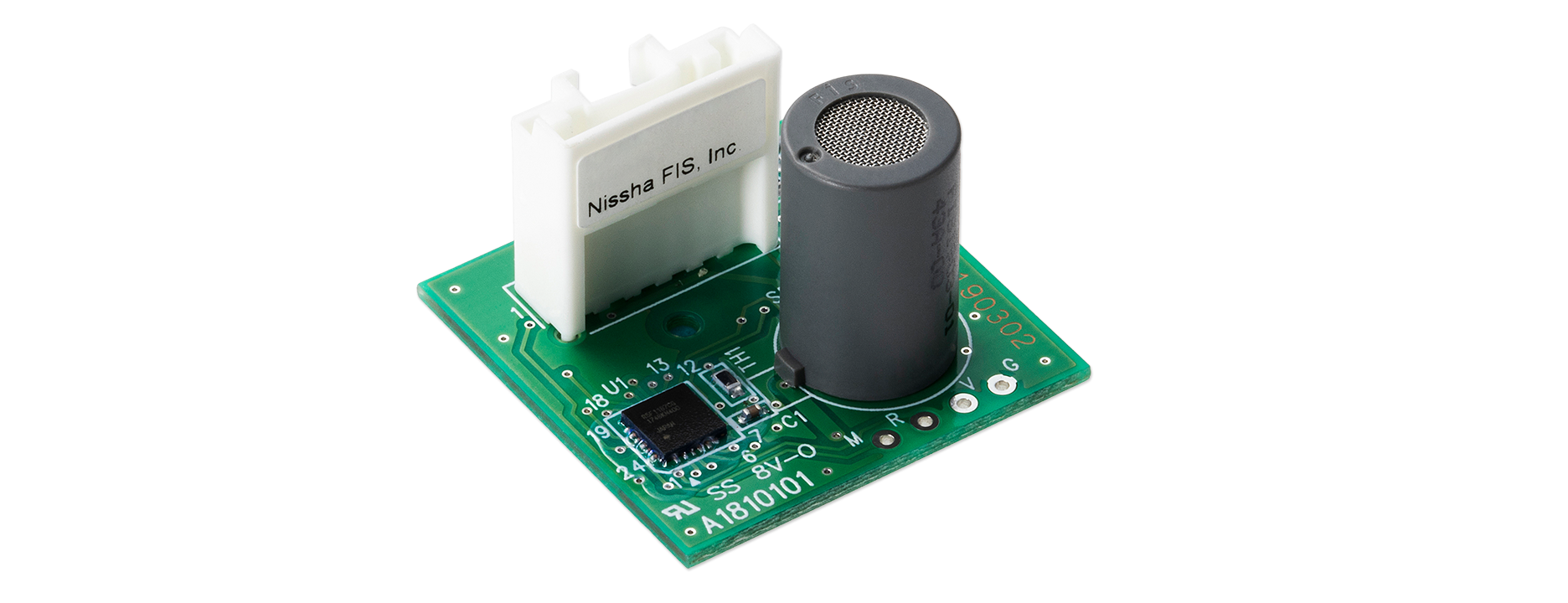

Sensor Hardware

The sensor module is available individually or with a case for protection and mounting.

Features of the sensor that reduce the maintenance services

Long life of 15 years

It does not require calibration after installation and can be used for 15years without replacing the sensor.

Equipped with a filter for miscellaneous gases

The system is equipped with filters for spray gases used in daily life to reduce the risk of false alarms.

Technical White Paper is here

Get the detail sensor specifications,

responsivity and selectivity data.

DOWNLOAD