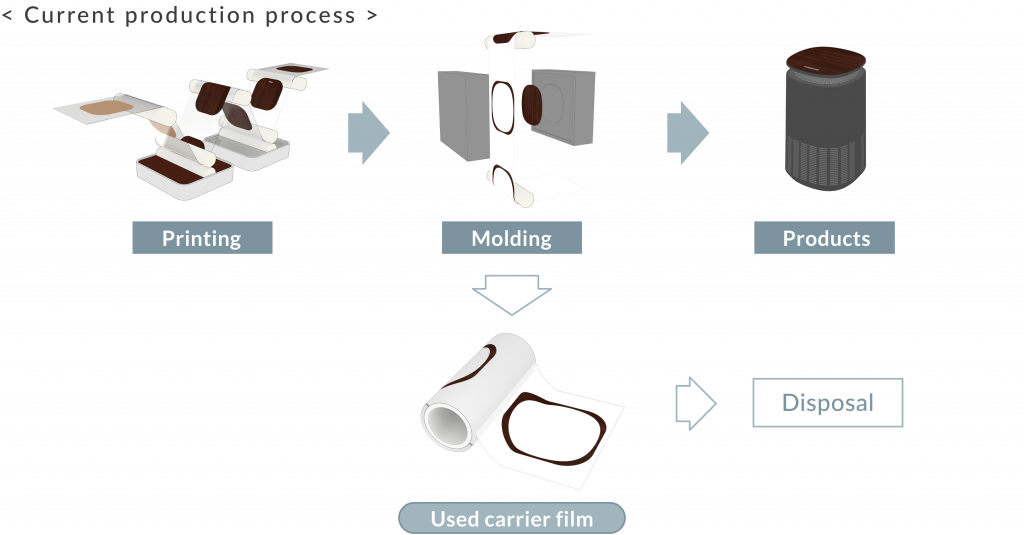

The Challenges of Recycling Printed Carrier Films

In recent times, there has been a growing emphasis on the circularity of plastic resources, with an increasing demand for improved material and chemical recycling rates. On the other hand, in our company’s transfer method, the PET film, which serves as the carrier film, always becomes waste. However, the disposal method was previously limited to thermal recovery.

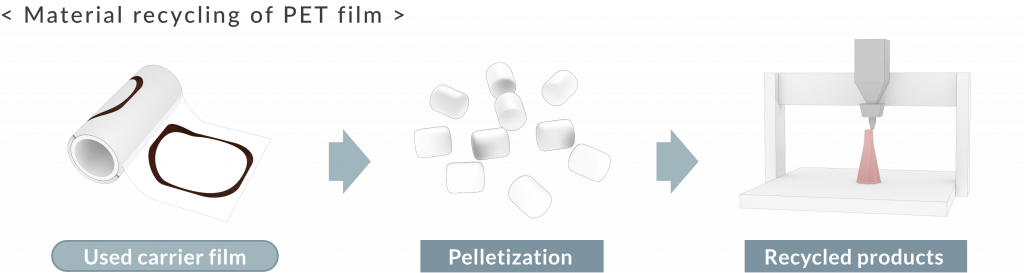

When it comes to material recycling, there has been a challenge with the carrier film, as it contains not only PET but also residual printing ink, making it difficult to pelletize. However, we have successfully achieved material recycling of carrier films by adjusting pre-processing and pelletization conditions.

PET Carrier Film × 3D Printing Technology

Nissha has successfully created practical molded products by combining carrier film pellets with a 3D printer. The benefits of utilizing 3D printing include the ability to fabricate complex shapes and being mold-less, which helps reduce costs and energy associated with mold production. Moreover, by incorporating color masterbatch, it is also possible to add vibrant value to recycled products.

Achieving a Sustainable Manufacturing Process

As the importance of addressing environmental issues continues to be emphasized, we have created molded products using recycled materials by pelletizing discarded carrier film and leveraging the power of 3D printing.

Our company aims to put an end to the disposable culture and promote long-term engagement with products and materials. The introduction we provided today marks the first step in this direction.

We are planning to continue our efforts in the material recycling of carrier film, aiming for environmentally friendly practices and more efficient utilization of resources.

If you are interested, please contact us through our Inquiries form.