Tackling Challenges in Recycling Carrier Films and Exploring New Potentials for Recycled Materials

This article is the second installment of our ongoing exploration into recycling used carrier films, a topic we introduced in a previous post.

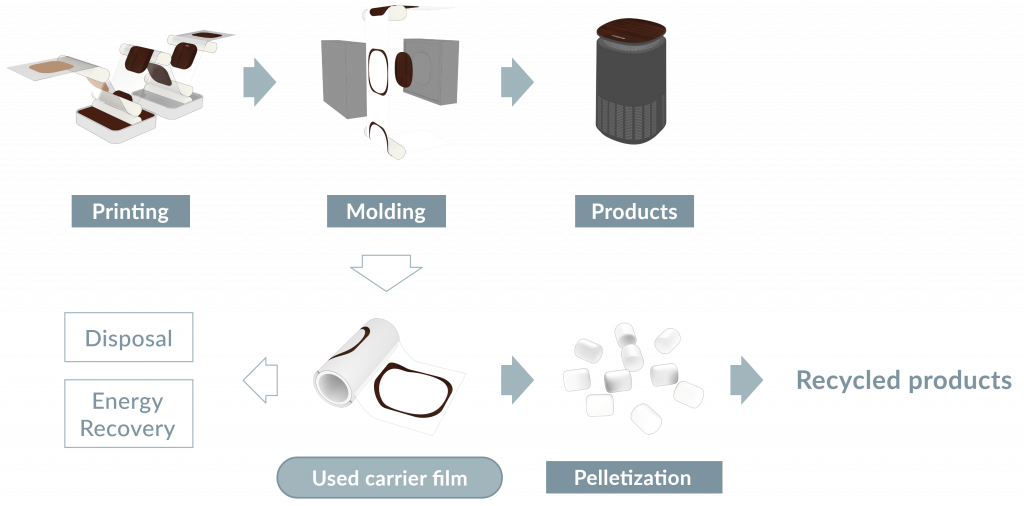

Carrier films, essential in the transfer method, are PET films that are typically discarded after a single use, making them as one-way plastics. In our own transfer method, a significant amount of PET film ends up as industrial waste, previously limited to thermal recovery (energy recovery). While recycling PET into recycled resin is preferable from a waste reduction and resource circulation perspective, recycling printed carrier films has been challenging due to the presence of inks and other non-PET materials.

To address this issue, we adjusted pre-treatment and pelletization conditions, successfully enabling the material recycling of carrier films. Simultaneously, we have been exploring ways to enhance recycled PET resin with new value and applications.

Following our previous experiment with 3D printing to create unique items from recycled carrier film pellets, this time we shifted our focus towards producing one-of-a-kind molded items using small-scale production techniques.

Recycling Carrier Films × Unique Aesthetic Value with Small-Scale Injection Molding

The desktop-sized injection molding machine we used, the Mold Lock®, brings versatile plastic molding technology to a compact, user-friendly desktop scale. Compared to large-scale equipment used in mass production, this machine significantly reduces costs and energy consumption, making it an ideal process for the initial phase of material recycling. Unlike traditional injection molding machines that use screws for melting resin, this machine allows for the blending of different colored resins to create marbled and vivid designs.

In this project, we utilized the slightly yellowish tint of the recycled PET pellets and the unique characteristics of this molding machine to create a marble-patterned pen tray. Unlike typical injection molded products, each pen tray has a unique and beautiful flow pattern, making every piece one-of-a-kind. This marbled pattern truly embodies a CMF narrative that originates from the material recycling process. Such a product, with its inherent story, can serve as a reminder of the importance of valuing materials and products.

Achieving a Sustainable Manufacturing Process

As part of our second phase in exploring the material recycling of used carrier films, we presented molded products made from recycled PET using the Mold Lock® desktop injection molding machine.

We aim to expand the possibilities of recycling by integrating various technologies through our projects.

Please look forward to our third installment, coming soon.

Samples of the pen trays produced in this project are also featured in “CMF DESIGN 2024.”

Please note that the contents discussed in this article represent experimental efforts towards implementing material recycling.