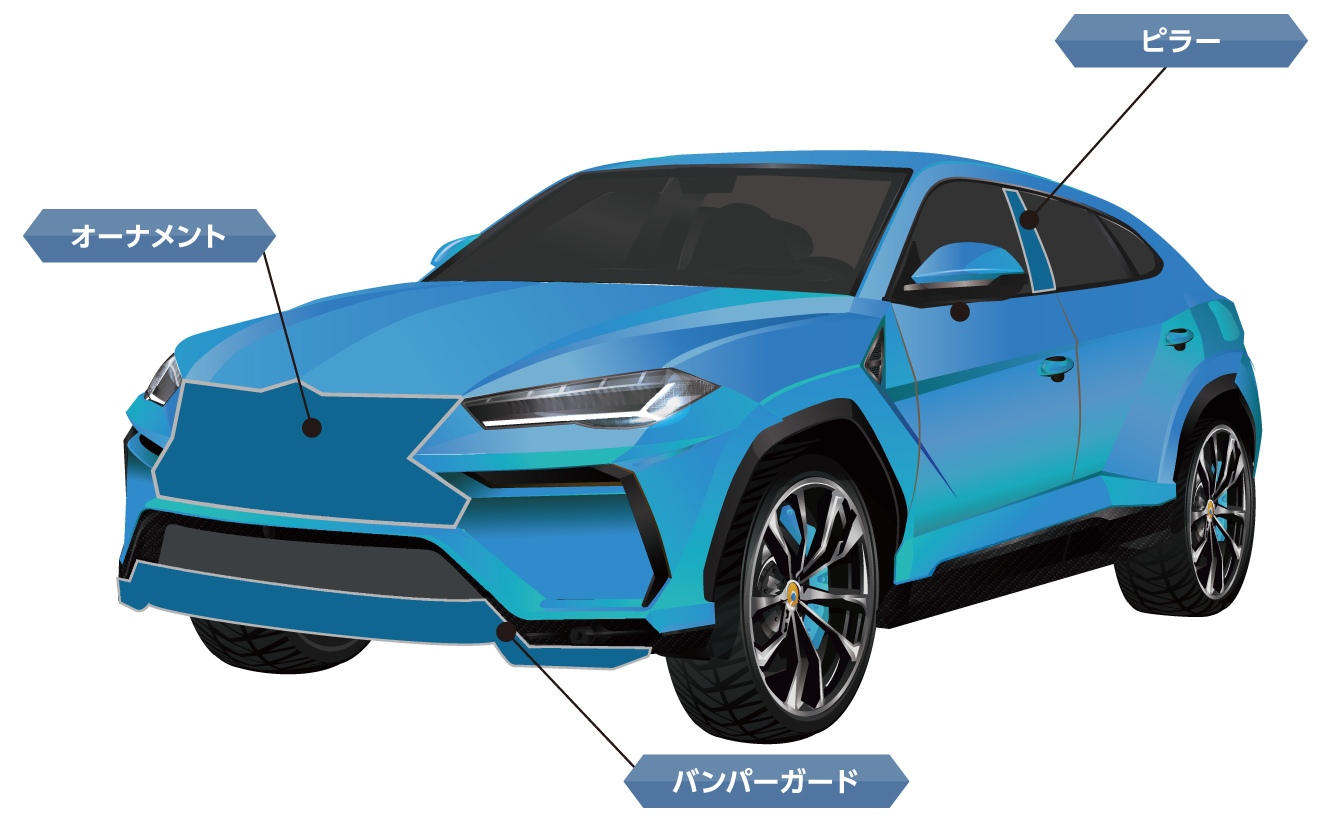

自動車外装部品へのフィルムヒーター組み込み加工

LiDARやIRセンサーの機能を維持する

防曇・解氷用ヒーター付きのプラスチックパーツを製造

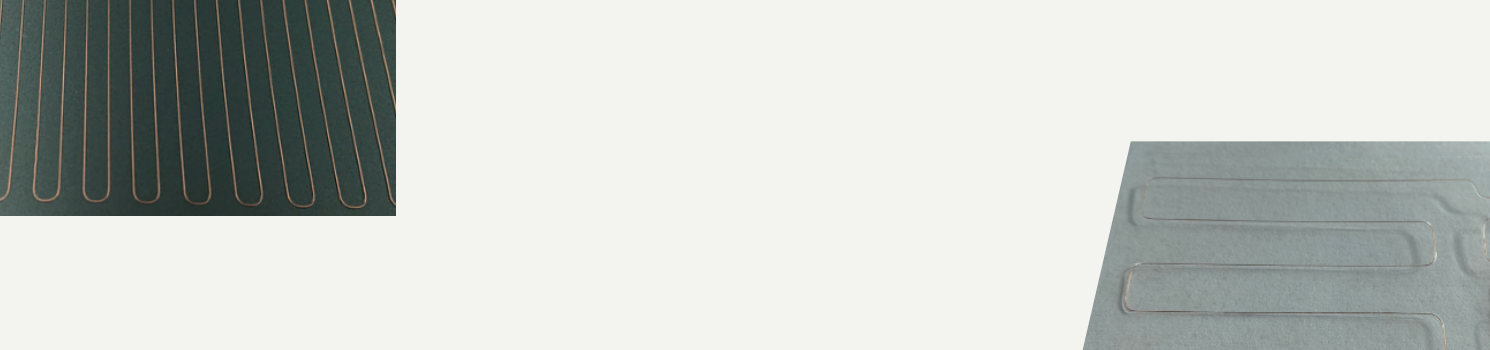

ワイヤー埋め込み型フィルムヒーター

・電波透過性を確保したワイヤーパターン設計

・成形品組み込みまでワンストップで対応

・IMD/IML(加飾同時成型)も対応。

デザインから提案可能。

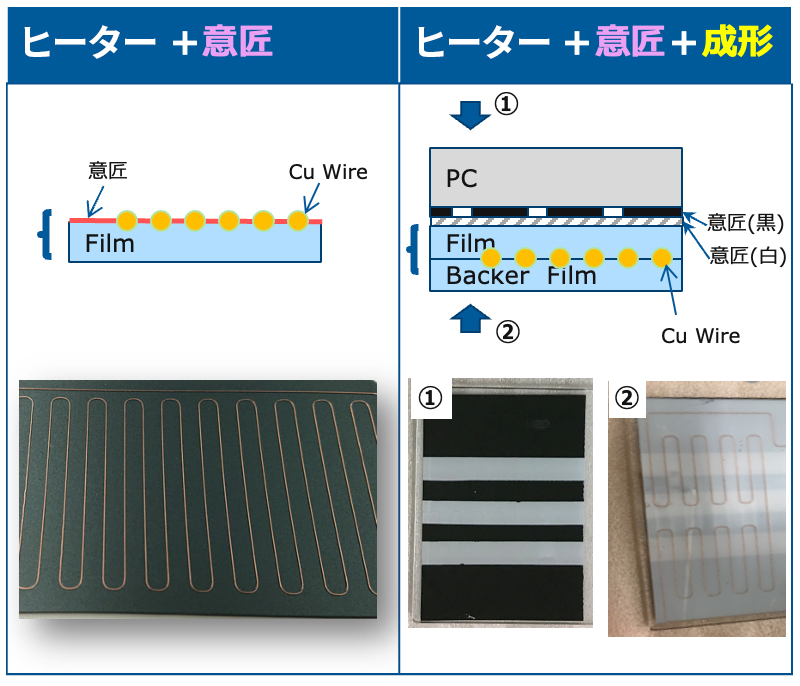

開発可能な製品形態

・ヒーター+意匠

・ヒーター+意匠+成形

除霜実験データ

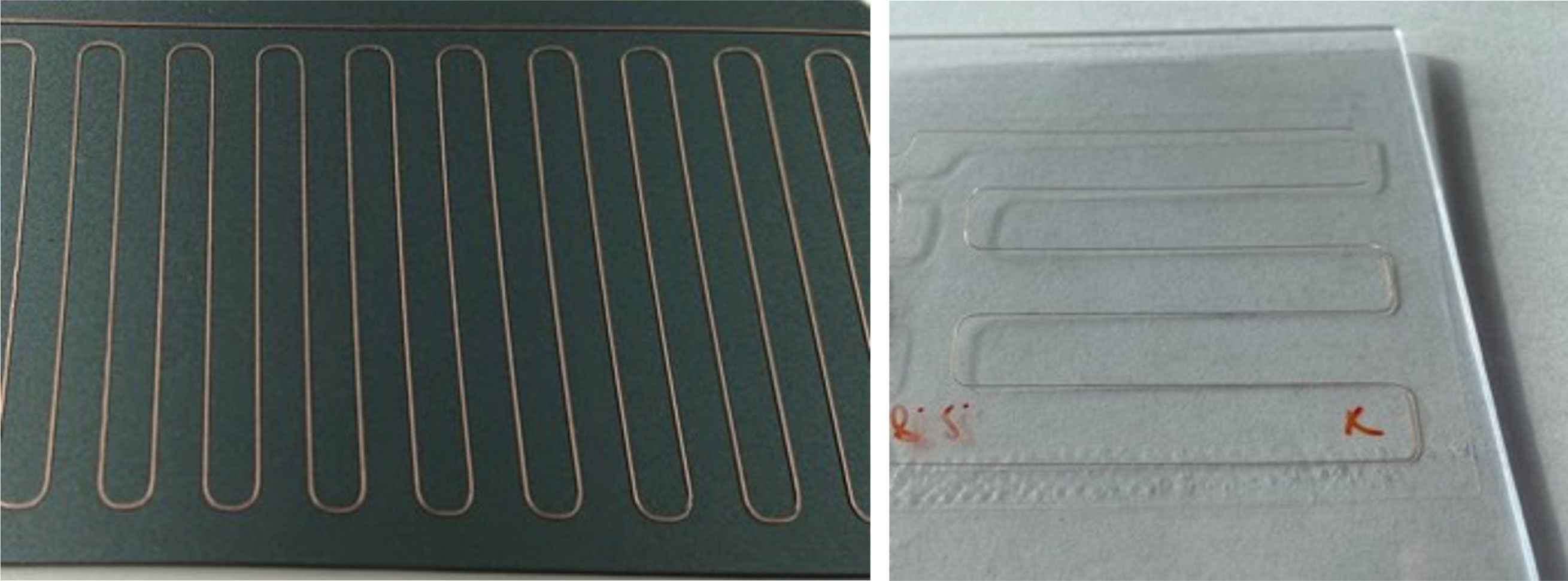

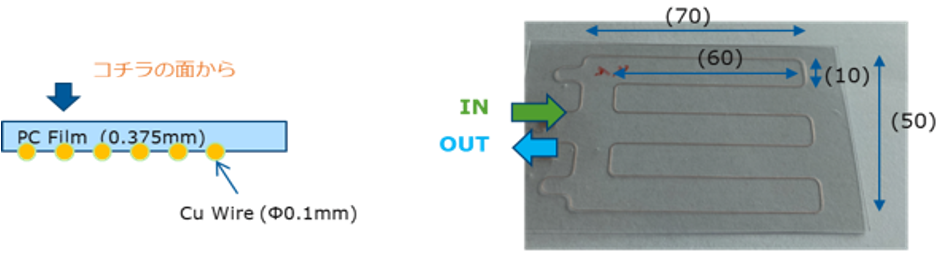

サンプル構成

PCフィルムの上にヒーター(ワイヤー)を形成

サンプルサイズ70×50mm

PCフィルム側から加熱特性を評価

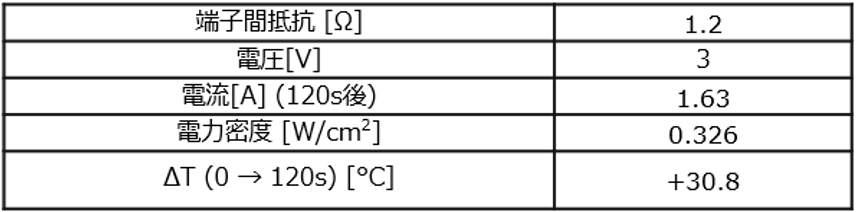

電気特性・加熱特性

室温環境で3V印加すると120秒後に表面温度が+30.8℃変化します。

この昇温性能により、寒冷地で雪や霜を融かします。

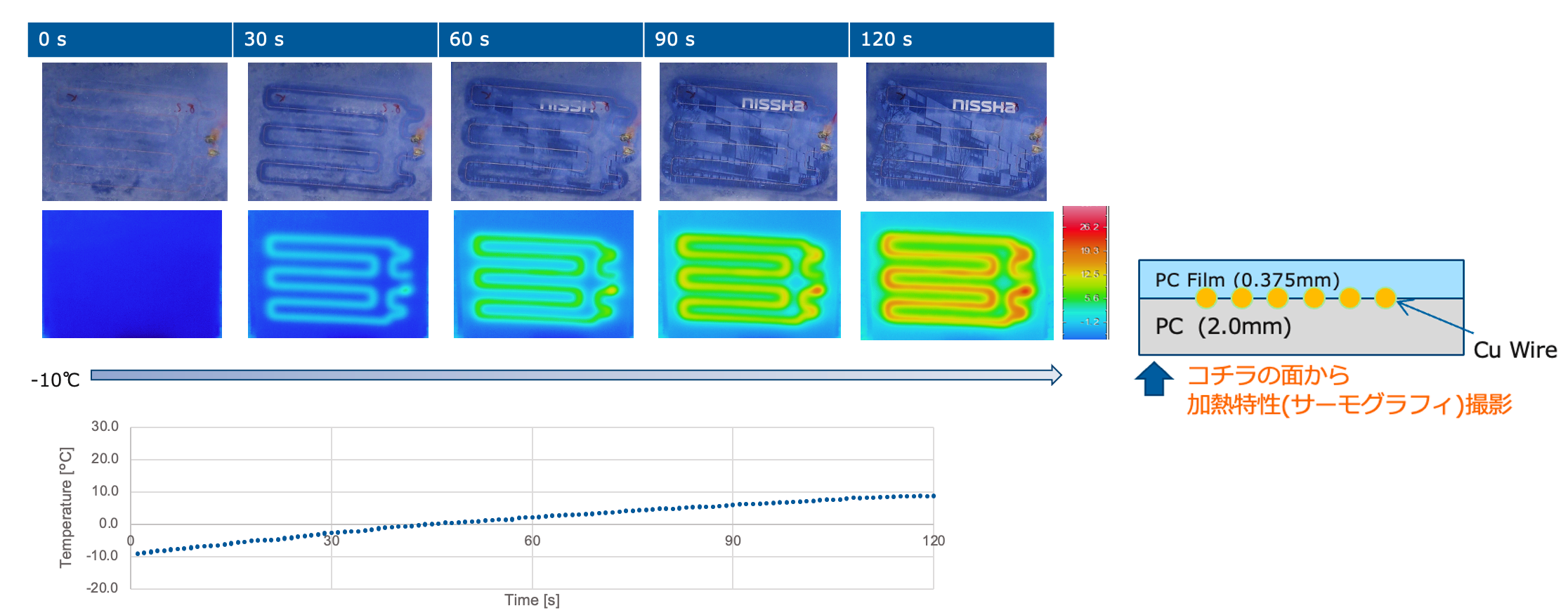

<室温環境下>

ヒーターの電源ONと同時に、ワイヤー部の温度が上昇し、全面除霜します。

※120秒後に、サンプル表面温度 約20℃上昇

フィルムヒーターの開発、製造はNISSHAにご相談ください

採用事例

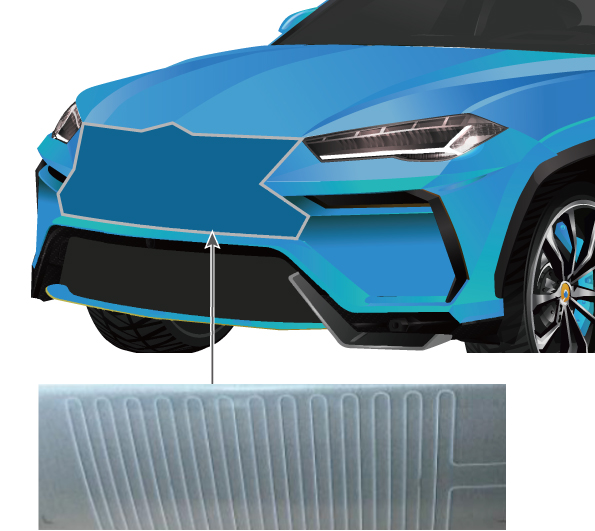

EV車向けワイヤーヒーター付きフロントパネル

NISSHAのワイヤー埋め込み型フィルムインサート成形品は、LiDARを搭載したEVフロントパネルに採用されています。