Automotive Injection Molding: From Basics to Advanced Decoration

Fundamentals of Injection Molding in the Automotive Industry

Injection molding is one of the most widely used manufacturing methods in the automotive sector. It combines precision, repeatability, and scalability, making it ideal for producing both functional and decorative vehicle parts. The process allows automakers to shape complex plastic components with consistent quality at high volumes, balancing performance and cost in modern vehicles.

What Is Injection Molding?

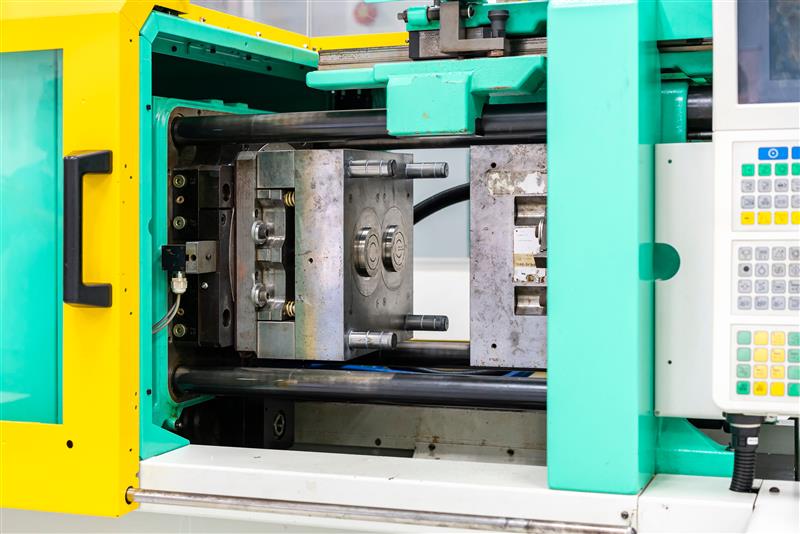

Injection molding is a manufacturing process that shapes molten plastic into precise forms using high pressure and precision molds. The method has a long history in automotive production, evolving from early thermoset applications to today’s high-performance thermoplastics.

Initially, car components were mostly metal. Over time, the need for lighter weight, better fuel economy, and improved acoustic performance drove the shift to plastics. Injection molding automotive processes support this transition by offering consistent, high-volume manufacturing of durable plastic components.

At its core, the process involves heating plastic pellets until molten, injecting the material into a mold cavity, cooling it under controlled conditions, and ejecting the finished part. This simple but efficient cycle supports the mass production of plastic injection molding automotive parts such as dashboards, grilles, and trim panels.

Automotive manufacturers favor this method because it enables:

- Lightweight construction, reducing vehicle mass and improving efficiency.

- Short cycle times, increasing production throughput.

- Stable dimensional accuracy, even for detailed designs.

- Design flexibility, allowing engineers to integrate multiple functions within one molded part.

These characteristics have positioned injection molding as a core process in vehicle manufacturing for decades.

Why Injection Molding Is Chosen for Automotive Parts

Automakers choose injection molding for both technical and economic reasons. The process provides several key advantages that make it indispensable in large-scale production.

1. Scalable for High-Volume Manufacturing

Once the tooling is set, each molding cycle produces parts identical to the last. This consistency supports long production runs where millions of pieces must meet the requested specifications.

2. Cost-Effective at Scale

Although mold fabrication requires investment, the cost per part drops significantly with volume. For Tier-1 and car brands, this scalability is critical for controlling unit costs without sacrificing quality.

3. Short Cycle Times

A complete molding cycle often takes under a minute. Automated loading and cooling systems enhance productivity, enabling just-in-time production.

4. High Repeatability and Dimensional Stability

Precision molds ensure every component fits seamlessly with others in assembly. The high repeatability of injection molding minimizes rework and quality variation.

5. Metal Replacement for Lightweighting

By replacing metal parts with engineered plastics, manufacturers reduce total vehicle weight and improve acoustic performance. Lightweight plastics help enhance fuel economy and extend EV driving range.

6. Durability and Resistance

Modern polymers offer excellent durability against heat, UV exposure, and impact. This makes them suitable for exterior components that must maintain performance over years of use.

7. Wide Material Portfolio

From polypropylene and ABS to polycarbonate and nylon blends, engineers can select materials optimized for mechanical strength, temperature resistance, or aesthetic finish.

8. Design Flexibility

Injection molding supports complex shapes, undercuts, and integrated features such as clips or guides. Engineers can design components that combine structure and decoration in one step.

Typical Automotive Parts Made by Injection Molding

Automotive designers rely on injection molding to manufacture a broad range of plastic components across both interior and exterior areas. The method supports different resin grades, surface finishes, and textures to match design and engineering goals.

Common interior components include:

- Instrument panel clusters and display housings

- Center consoles and dashboard faceplates

- Door trims and decorative panels

- Switch bezels and control knobs

Common exterior components include:

- Front and rear bumpers

- Radiator grilles and emblems

- Lighting housings and lamp covers

- Wheel caps and exterior garnish parts

Each of these items benefits from the repeatable precision of molding and the ability to add color, gloss, or texture directly within the process. By adjusting resin composition and mold design, manufacturers can meet performance requirements for impact strength, UV stability, and finish quality.

Process Flow to Make Injection-Molded Automotive Parts

Producing a high-quality automotive component through injection molding involves a detailed series of steps, each contributing to consistency and efficiency.

1. Mold Design

Engineers design the mold based on the component’s geometry, ensuring proper cavity flow, gate placement, and cooling channels. A well-designed mold supports uniform filling and smooth ejection.

2. Resin Drying

Before molding, plastic pellets must be dried to remove moisture. Trapped water can cause defects like bubbles, streaks, or reduced strength.

3. Injection (Fill and Pack)

The molten resin is injected into the mold cavity under pressure. After the cavity is filled, packing pressure is applied to compensate for shrinkage during cooling and ensure complete material distribution.

4. Cooling

The mold’s internal cooling channels regulate temperature, allowing the part to solidify evenly.

5. Ejection

When the part has cooled sufficiently, ejector pins release it from the mold cavity. This step must be gentle to prevent marks or distortion.

6. Trimming and Finishing

After ejection, excess material at the gate or along the edges is removed. This step ensures that each part meets dimensional and cosmetic standards.

7. Inspection and Quality Check

Every batch undergoes inspection for dimensional accuracy, surface quality, and color consistency. Automated systems often support this process for repeatability.

8. Packaging and Shipping

The approved parts are packed securely to avoid deformation during transport to assembly plants or Tier-1 suppliers.

Common Decoration Methods for Injection-Molded Automotive Parts

Automotive designers rely on various decoration methods to give injection-molded plastic parts their final look and feel. Beyond color, these finishes influence brand appeal, surface protection, and user experience.

Decoration also communicates quality and supports functional design, such as texture for grip or light transmission. Techniques range from post-mold coatings to in-mold solutions that integrate design during production. Each approach offers a different balance of appearance, durability, and process efficiency suited to automotive interiors and exteriors.

Post-Mold Painting and Coating

Painting is one of the most established decoration methods for molded plastic parts. It involves spraying a color or protective coating onto the surface and curing it in an oven to achieve gloss, smoothness, and durability.

A typical paint line includes multiple steps: cleaning, priming, color coating, and clear finishing. These layers help resist UV damage, wear, and chemicals.

While effective, post-mold painting has drawbacks. It consumes significant energy due to repeated drying cycles, and solvent-based coatings produce VOC emissions that require control systems. The process also demands dust-free environments to maintain surface quality.

Automakers increasingly explore integrated decoration methods that provide similar finishes with lower energy use and smaller production footprints.

Molded-in Color (Masterbatch Coloring)

Molded-in color serves as an alternative to painting by mixing pigment into the base resin before molding. A color masterbatch, rich in pigment and additives, is combined with plastic pellets in controlled ratios. During molding, this blend fills the cavity and forms a part that already has its final color.

This approach eliminates painting lines, reduces waste, and ensures excellent color consistency across large volumes. It’s efficient for plastic injection molding automotive parts such as trims and interior panels.

However, the design range is limited. Effects like metallic shimmer, transparency, or gradient patterns are difficult to reproduce through masterbatch coloring alone. Despite the limitations, its simplicity, cleanliness, and cost advantages make molded-in color a preferred choice for high-output applications.

Tool Surface Finishes (SPI/VDI, Etching, Polishing)

Tool surface finishing defines how a molded part looks and feels straight out of the mold. By adjusting the cavity’s roughness or gloss, manufacturers transfer fine surface detail directly to the plastic.

Two common standards guide this work: SPI grades range from mirror-polished surfaces to matte finishes, while VDI levels use electrical or chemical texturing to create specific roughness.

This method eliminates secondary finishing and helps achieve textures like brushed metal or soft-touch matte. However, maintaining consistency requires precise process control. Excess pressure or mold wear can distort delicate patterns and reduce mold life.

With proper maintenance, surface finishing delivers high-quality decorative effects efficiently and repeatably.

Hydrographics (Water Transfer Printing)

Hydrographics, or water transfer printing, allows full-surface decoration of three-dimensional parts. A printed film, bearing patterns such as wood grain or carbon fiber, is floated on a water tank and activated by a chemical spray.

The part is dipped through the floating design, transferring the pattern evenly across its surface. After rinsing and drying, a clear topcoat adds gloss and protection.

This method achieves continuous decoration on complex shapes that painting or printing can’t easily cover. However, alignment and stretching control are critical; distortion can occur on curved sections. Process optimization ensures uniform results while minimizing film waste.

Hydrographics remain a popular option for decorative interior and exterior automotive parts.

Hot Stamping (Heat Transfer Foil)

Hot stamping decorates specific areas of a molded part using heat and pressure. A metallic or colored transfer foil is pressed against the plastic with a heated die, bonding a thin decorative layer to the surface.

This process produces sharp, reflective accents and consistent color coverage. It’s ideal for emblems, trims, and logo details that need a premium metallic finish.

Since no drying or solvents are involved, hot stamping offers clean production and minimal emissions. However, achieving even adhesion depends on surface uniformity and precise temperature control. Uneven pressure or rough textures can cause peeling or color variation.

With correct tooling, hot stamping provides durable, visually appealing decoration in a single, efficient step.

Wrapping (Lamination on Molded Substrates)

Wrapping, or lamination, bonds decorative or tactile films to molded plastic substrates. Using heat, pressure, and adhesives, materials such as PVC, TPU, PU, or synthetic leather conform to the part’s surface.

This method creates soft-touch finishes with seamless transitions, often used for dashboards, armrests, and door trims. It enhances both comfort and visual appeal, meeting the growing demand for refined interiors in modern vehicles.

Adhesive choice is critical. It must maintain strength under heat, humidity, and long-term wear. Low-VOC and solvent-free adhesives are now preferred to align with environmental goals.

Process control is equally important. Temperature uniformity, film tension, and draw depth determine how well the surface conforms without wrinkles or springback. Precise trimming ensures neat edges and consistent thickness.

Although wrapping adds complexity compared with paint or molded-in color, it offers unmatched tactile quality and luxury appearance. When combined with automated handling systems, it delivers premium results at automotive production speed.

Printing (Pad Printing / Screen Printing / UV Inkjet / Laser Etching)

Printing enables precise, localized decoration on molded surfaces. Each technique serves a specific need in automotive design and branding.

- Pad Printing transfers ink using a flexible silicone pad, ideal for curved shapes like buttons or switches.

- Screen Printing applies bold, opaque layers through a mesh stencil, suitable for flat panels and display covers.

- UV Inkjet Printing jets digital inks directly onto the part and cures them instantly with UV light, enabling variable graphics or serial data.

- Laser Etching removes thin surface layers to reveal contrasting colors or create illuminated icons.

Each method balances speed, durability, and cost, helping automakers combine functional labeling with distinctive visual appeal.

Spotlight Decoration for Automotive Injection-Molded Parts: In-Mold Decoration / In-Mold Labeling (IMD/IML)

Modern vehicles require surfaces that look sophisticated and function intuitively. In-mold decoration (IMD) and in-mold labeling (IML) meet these needs by combining molding and decoration in a single process. Unlike post-processing methods such as coating or painting, these technologies complete both steps inside the mold, saving time and improving consistency.

By integrating graphics, patterns, and protective layers during molding, IMD and IML deliver durable finishes that withstand temperature shifts, cleaning, and UV exposure. These technologies are core to injection molding automotive innovation, offering automakers a way to simplify production while achieving high-end aesthetics.

What Are IMD and IML?

IMD and IML are advanced decoration methods that integrate surface design directly into the molding cycle. Both techniques use printed films but differ in how those films interact with the molded part.

In-Mold Decoration (IMD) transfers only the printed ink layer from a decorative film onto the surface during molding. The carrier film does not remain on the finished product. This makes IMD ideal for high-speed, continuous production because the film advances roll-to-roll through the mold. A single shot completes decoration and surface protection, reducing post-processing steps.

In-Mold Labeling (IML), by contrast, keeps the decorated film attached to the molded part. The pre-printed and pre-formed film is placed inside the mold before resin injection. The molten plastic bonds with the film, embedding it as an outer layer. This method produces thicker, high-quality finishes with visual depth and texture.

IML is especially suitable for deep-draw parts and complex shapes that require flexibility in pattern and form. It also enables the integration of functional elements, such as light transmission, texture, or tactile feedback, into the part’s surface.

Both IMD and IML create consistent, paint-free surfaces that minimize variation between batches. They also reduce VOC emissions and shorten manufacturing time by completing molding and decoration together.

Why IMD/IML for Automotive Decoration

IMD and IML have become essential for manufacturers seeking efficiency and precision in plastic injection molding automotive parts. Their advantages extend beyond appearance where each process improves production flow, cost control, and sustainability.

1. Streamlined Production

Since decoration occurs during molding, separate painting and drying stages are eliminated. This shortens cycle time, reduces part handling, and lowers the risk of contamination or scratches. The result is higher yield and faster throughput.

2. Consistent Appearance

Because graphics and colors form directly within the mold, every part maintains uniform tone and texture. This precision minimizes color deviation between production lots and ensures reliable fit-and-finish across vehicle interiors and exteriors.

3. Environmental and Energy Benefits

IMD and IML eliminate the need for paint booths and large drying ovens. They produce minimal VOC emissions and use less energy for curing, contributing to lower CO₂ output. This supports automakers’ sustainability goals and helps meet tightening global regulations.

4. Reduced Factory Footprint and Maintenance

With fewer processing stations, factories can operate more compactly. Maintenance costs drop as painting lines and waste treatment systems become unnecessary.

5. Design Flexibility

IMD and IML enable complex patterns, gradients, and transparent effects that traditional paint cannot easily replicate. They also allow for integration with functional technologies such as backlighting and sensors.

Together, these factors make IMD and IML forward-looking solutions that align with the automotive industry’s drive toward cleaner, smarter, and more efficient production.

Nissha’s Automotive Decoration Technologies (IMD/IML) — Under the “Nissha SurfaceWorks” Brand

Nissha delivers advanced injection molding automotive decoration solutions through its SurfaceWorks brand. This suite of technologies combines function, design, and durability in one integrated process.

By applying in-mold decoration (IMD) and in-mold labeling (IML), Nissha provides automakers and suppliers with visually refined and highly consistent plastic components. These technologies reduce manufacturing steps and enable complex textures, patterns, and lighting effects.

From interior control panels to exterior trim, Nissha SurfaceWorks offers materials engineered to perform under demanding automotive conditions. Each surface maintains its color, gloss, and dimensional stability over time, reflecting both quality and precision.

Key Features

Diverse Aesthetic Expressions

Nissha’s IMD and IML technologies allow automotive designers to achieve a wide range of visual effects directly in the molding process. The company’s expertise in film design and ink technology supports various appearances, such as metallic tones, brushed textures, soft matte surfaces, and deep gradients, without additional coatings.

Each film layer is engineered to resist fading, scratching, and chemical wear, maintaining long-term appearance quality. Advanced printing and registration control ensure that fine patterns, icons, and alignment remain accurate, even on curved or contoured parts.

These capabilities give manufacturers flexibility to match brand design themes across models and regions. The consistency and precision of Nissha’s decorative films help create interior environments that look refined and unified across every production run.

Dead-Front (Hidden-lit) with Light Transmission

The Dead-Front or Hidden-lit function is one of Nissha’s signature decoration features under the SurfaceWorks brand. It allows icons or indicators to remain invisible when unlit but appear clearly when illuminated from behind.

This effect is achieved through precise control of ink opacity and film layering during the IMD or IML process. By embedding semi-transparent areas within the film, light passes through only when activated, creating a clean and modern interface.

In vehicle interiors, Dead-Front designs are used for switches, touch panels, and ambient lighting controls. The approach eliminates separate cover panels or light windows, simplifying assembly and improving design integration.

The result is a smooth, seamless surface that supports both aesthetic appeal and functional clarity. This capability exemplifies how plastic injection molding automotive parts can combine design with technology in a single molded structure.

Adding Diverse Textures and Tactile Sensations

Beyond color and pattern, Nissha’s IMD and IML technologies add distinctive textures that enhance tactile quality. Through precise control of mold surface design and film layering, these technologies produce finishes ranging from soft-touch matte to finely grained leather-like patterns.

Such tactile effects add comfort and perceived quality inside vehicle cabins. They help differentiate brands and models while supporting ergonomic and aesthetic goals.

Textured finishes can also reduce glare, mask fingerprints, and improve scratch resistance, which are important features in areas frequently touched by drivers and passengers. Because these surfaces are formed during molding, no secondary coating is required, ensuring uniformity and durability.

The ability to combine tactile feedback with decorative appeal demonstrates how Nissha’s solutions elevate interior design standards for injection molding automotive components.

Other Benefits of Nissha IMD/IML

Nissha’s IMD and IML technologies provide multiple benefits that streamline production and support sustainability.

1. Design FlexibilityEngineers can integrate lighting, symbols, and graphics directly into the molded surface. Gradients, metallic tones, or transparent sections can be adjusted easily through film and ink selection.

2. Fewer Manufacturing StepsDecoration occurs during molding, removing the need for paint lines, drying ovens, and masking operations. This simplifies workflows and shortens lead times.

3. Environmental EfficiencyBy eliminating solvent-based coatings, IMD and IML reduce VOC emissions and energy consumption. They also generate less waste material, supporting carbon-reduction goals.

4. DurabilityDecorative films resist UV exposure, chemicals, and repeated contact, ensuring long-lasting color and gloss retention.

5. Consistency Across Production RunsColor variation and surface defects are minimized, maintaining uniform quality across large volumes of plastic injection molding automotive parts.

These advantages make Nissha’s IMD/IML processes an excellent fit for OEMs and Tier-1 suppliers seeking precision, reliability, and environmental responsibility in vehicle design.

Contact Nissha About Decorating Injection-Molded Automotive Parts

Nissha offers expert consultation and technical support for automakers and suppliers interested in advanced surface decoration. Whether your focus is design integration, durability, or production efficiency, the SurfaceWorks team can recommend solutions tailored to your application.

To discuss your project or request samples, please contact Nissha here.