Chipping resistance

Film insert molded products for Automotive exterior components

Film insert molding delivers chipping resistance at required level for automotive exterior decorative components without painting

What is chipping-resistance testing?

Chipping-resistance testing is endurance testing for evaluating levels of damage that molded-product surfaces sustain from impacts by stones, gravel, and so on. It is also referred to by names such as gravelometer testing and stone-impact testing.

A molded product is mounted on a testing stand, and gravel is sprayed onto the surface of the product at a fixed pressure. Following this, the degree of deterioration of the surface is evaluated.

In the case of the chipping-resistance testing of automotive components, there are testing standards that include JASO M104, SAE J400, ISO 20567-1 Test Method B, and ASTM D3170-3.

Paintless components that have outstanding chipping resistance

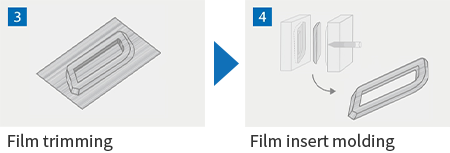

Film insert molding is a method in which design films are preformed, and then undergo integral molding by loading them into an injection mold.

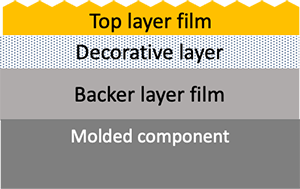

Molded-product surfaces are protected by acrylic transparent films. Therefore, overcoating treatment is not carried out.

General acrylic films do to the meet the requirements of chipping-resistance testing at the level for painted components.

Thus, we at Nissha specially process the surfaces of top-layer acrylic films, and have thereby realized surface-protection films with outstanding chipping resistance.

Chipping-resistance specifications of Nissha film-insert-molded products

Test standard: SAE J400

Testing conditions

Test angle: 90°

Spray pressure: 70 psi

Spray volume: 1.4 L

Test-environment conditions:

-20℃ ± 2℃, room temperature

Achievement of durability at level

required for application of product

as automotive exterior component

We have also met the required specifications for automotive exterior products in areas of durability testing other than chipping resistance, such as heat resistance and weather resistance.

Feel free to contact us

Benefits of film insert molded products

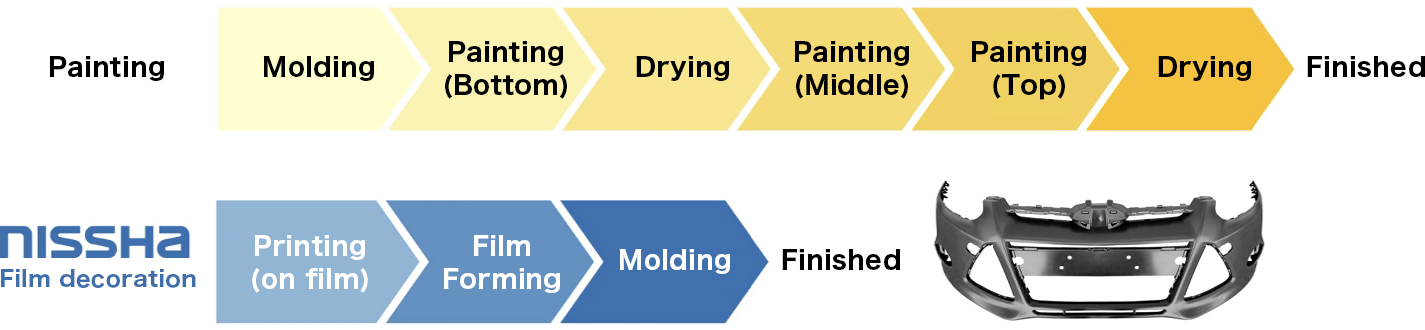

Manufacturing process with low environmental impact

Film insert molding is a method in which decorating is carried out at the same time as injection molding. The manufacturing process is extremely simple, and this is partly because no drying processes are required. As a result, CO2 emissions from the fabrication process are about 50% less compared with those from exterior-resin decoration through painting.

Realization of diverse designs

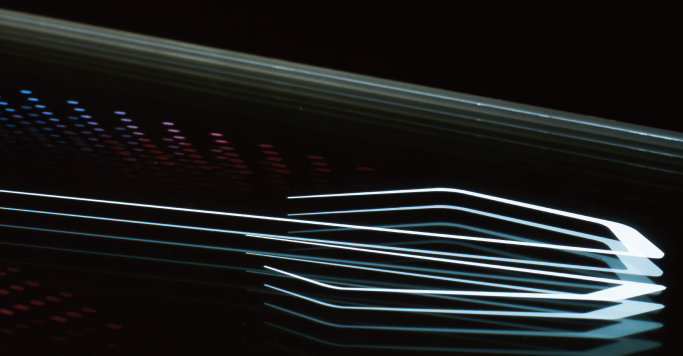

Various designs can be realized that cannot be achieved through painting.

The possible designs include metallic finishes, carbon-fiber patterns, and geometric designs, and furthermore, on the back surface of molded products, it is possible to achieve hidden-lit designs that incorporate LED light sources.

Carbon pattern

Hair line

Metallic color

Abstract pattern

translucent light emittion

(Dead front)

Geometric pattern

Contract manufacturing of decorative molded products for automotive exteriors.

Business models with supply chain

Film roll delivery

Film roll delivery is possible for those who mold it in house

Molded parts delivery

We can supply molded parts from Nissha’s global factories.

We can process molding at your preferred location worldwide.

We can provide service that starts with addressing customer’s questions and concerns

We are able to accommodate requests that include:

• Requests to just see films

• Requests to view molding samples

• Requests to receive prototypes for the presentation of drawings

We would like to encourage customers to first of all consult us.

Feel free to contact us