Radio-wave transparency

Film insert molding for automotive exterior components

The film-insert-molded products of Nissha have outstanding radio-wave transparency

Sensor components such as LiDAR have been designed to be incorporated into the back sides of skid guards and front grilles, and to not be visible from the outside. As such, the exterior plastic parts that cover such sensors now need to have radio-wave transparency so that they do not inhibit sensor functions.

Meanwhile, exterior plastic parts are often given metallic-type coatings. The metal pigments in such metallic coatings impact the transmission and reception of radio waves by sensors, and this has become an issue with regard to the development of advanced driver-assistance systems (ADAS).

A metallic tone designed film

that deliver outstanding radio-wave transparency

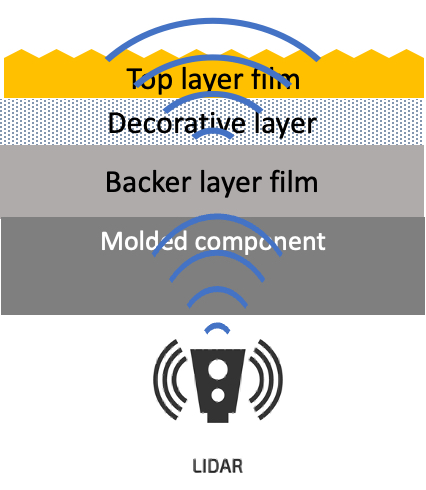

The insert films of Nissha are comprised of the following layers.

• Top layer: transparent film with outstanding durability

• Decorative layer: printed metal-deposition layer that provides design

• Backer: resin film that bonds with molding resin

In the case of decorative components with a metallic tone, metallic pigments made from metal particles are blended into the decorative layer. Metal particles are conductive so reflect and scatter the radio waves of sensors and thus can cause electromagnetic interference. The issue of radio-wave transparency is greatly influenced by the density and film-thickness of the metallic pigments in the decorative layer. Therefore, when designing the decorative layer, it is important to manage the blend ratio and film-thickness of the metallic pigments that are included in the coating agent.

We optimize the blend ratios of metallic pigments and strictly manage film-thickness during printing processes, and as a result of this, we have achieved the development of metallic-tone decorative films that do not affect sensor functions.

Ability to embed wire heaters

that prevent problems caused by snow accretion

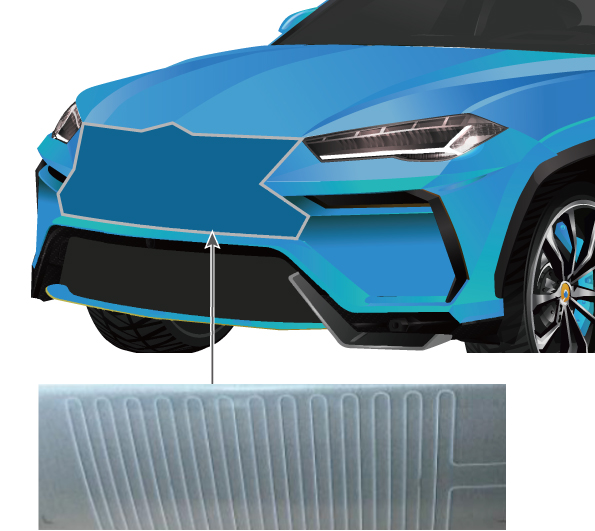

We embed wire heaters into exterior plastic parts as a measure against snow accretion on sensor transmitter surfaces, which is an issue for vehicles with cold-weather specifications.

The structure of the heater has been designed while taking into consideration radio-wave transparency so that sensor performance is not affected.

Embedded heater on Backside of the molded panel

Example of adoption

Front panel with wire heater for electric vehicle (EV)

A Nissha film-insert-molded product into which wire is embedded has been adopted for an EV front panel that is equipped with LiDAR.

Contract manufacturing of decorative molded products for automotive exteriors.

Business models with supply chain

Film roll delivery

Film roll delivery is possible for those who mold it in house

Molded parts delivery

We can supply molded parts from Nissha’s global factories.

We can process molding at your preferred location worldwide.

We can provide service that starts with addressing customer’s questions and concerns

We are able to accommodate requests that include:

• Requests to just see films

• Requests to view molding samples

• Requests to receive prototypes for the presentation of drawings

We would like to encourage customers to first of all consult us.

Feel free to contact us