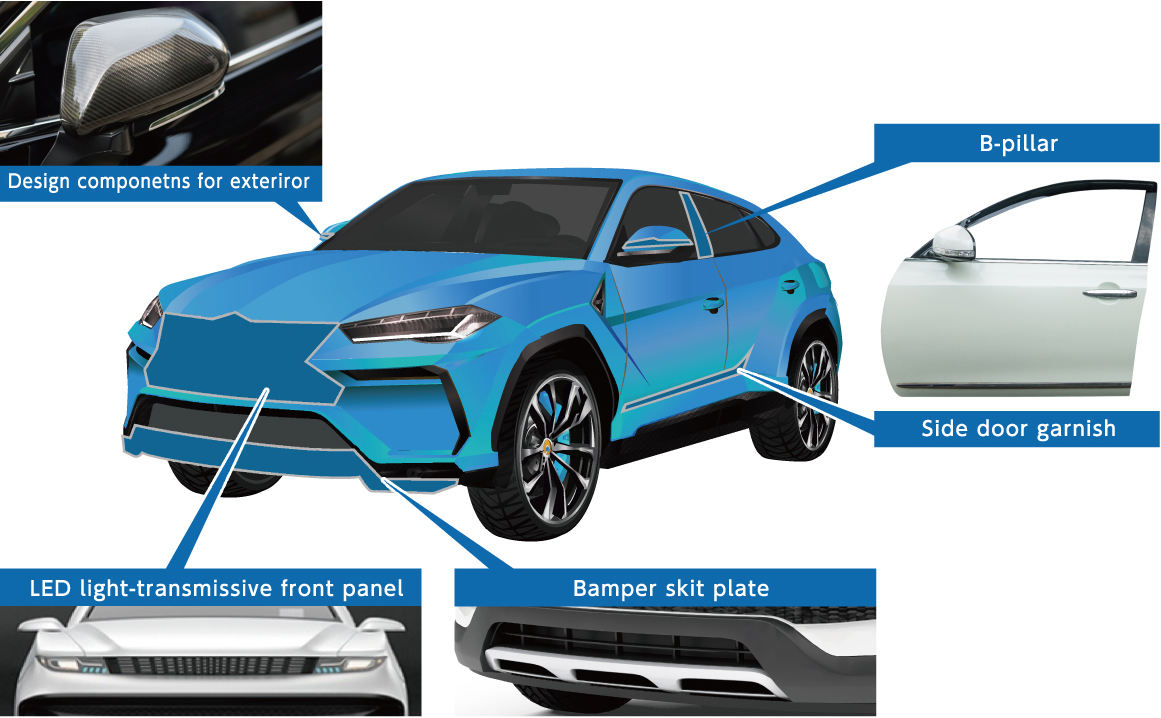

Large-scale plastic molding for automotive exteriors

Contract manufacturing of film insert molded products

Skid guards, front grilles, pillars…

Achieving decorative molding of large-scale plastic molded parts for automotive exteriors

Large-scale molding machines up to 850 tons

We can accommodate the contract manufacturing of large injection molded products for automotive exteriors.

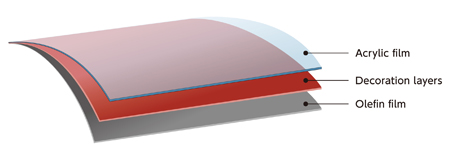

The Nissha film insert method is a technology in which decorative films are integrated at the same time as injection molding.

Thus, we are able to manufacture exterior components that are paintless and have a wide range of colors and finishes.

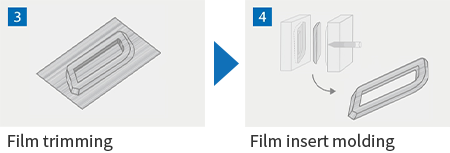

Film insert molding

Film insert molding is a method in which design films are preformed, and then undergo integral molding by loading them into an injection mold.

Since designs can be given during molding, processing can be carried out with a simpler process than with painting.

We can accommodate both the providing of just film materials, and the providing of insert molded products.

Achieving exterior parts-level durability without painting

For the top layer, we have adopted surface-protection films that pass chipping-resistance and various other durability tests, and this is possible because we specially process the surfaces.

Furthermore, our wide-ranging decorative printing processes can be applied to film processing for large molded products.

Our technologies

Film processing

Decoration:

gravure printing, screen printing, metal deposition

Lamination:

roll-to-roll lamination

Mold processing

Molding machines:100 tons to 850 tons

Compatible molding resins: TPO, PP, etc.

We can accommodate general molding resins that are used for exterior components.

Feel free to contact us

Design-rich exterior parts

by film insert molding

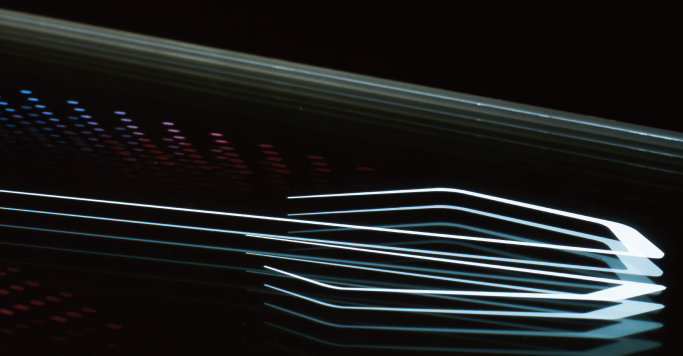

For the insert film for the exterior, a decorative layer is formed. The possible designs include hairline metallic finishes and carbon-fiber patterns, and furthermore, on the back surface of molded products, it is possible to achieve hidden-til-lit designs that incorporate LED light sources. Thus, we can achieve diverse designs that had been difficult with painting. Through our in-house CMF Design Team, we at Nissha propose high-quality designs while listening to the requests of customers.

Carbon pattern

Hair line

Metallic color

Abstract pattern

translucent light emittion

(Dead front)

Geometric pattern

Contract manufacturing of decorative molded products for automotive exteriors.

Business models with supply chain

Film roll delivery

Film roll delivery is possible for those who mold it in house

Molded parts delivery

We can supply molded parts from Nissha’s global factories.

We can process molding at your preferred location worldwide.

We can provide service that starts with addressing customer’s questions and concerns

We are able to accommodate requests that include:

• Requests to just see films

• Requests to view molding samples

• Requests to receive prototypes for the presentation of drawings

We would like to encourage customers to first of all consult us.

Feel free to contact us