Polypropylene in Automotive

Properties, Applications & Decoration

Polypropylene in automotive:

from material advantages to decoration

Polypropylene (PP) is widely used in vehicles because it balances lightweighting potential, durability, processability, cost efficiency, and recyclability. This page outlines where PP fits in automotive parts and how polypropylene decorative film enables premium, paint-less surfaces on PP components while keeping designs within the same material family.

Nissha’s polypropylene decorative film for automotive applications provides recycle-friendly surface decoration on PP (and PP-rich TPO) substrates—delivering matte, soft-touch, wood-grain, and metallic looks without paint while keeping the part in the PP family.

Want detailed material data or design possibilities?

Contact us anytime

What is polypropylene in automotive?

Polypropylene (PP) is a polyolefin thermoplastic used widely in automotive applications because it combines low density (supporting lightweighting), heat and chemical resistance, good processability, cost efficiency, and recyclability. A ~10% reduction in vehicle mass is associated with roughly 5–7% better fuel efficiency, which helps explain why many automotive interiors have shifted from ABS/PC-ABS toward polypropylene.

In automotive design, polypropylene appears in several families and blends to tune properties while staying within the same material group: neat PP for balanced performance and cost, impact-modified PP-EPDM for toughness, talc-filled PP for stiffness and dimensional stability, and PP-rich TPO grades often selected for exterior trims.

Polypropylene’s expansion in automotive:

from substrates to decorative film

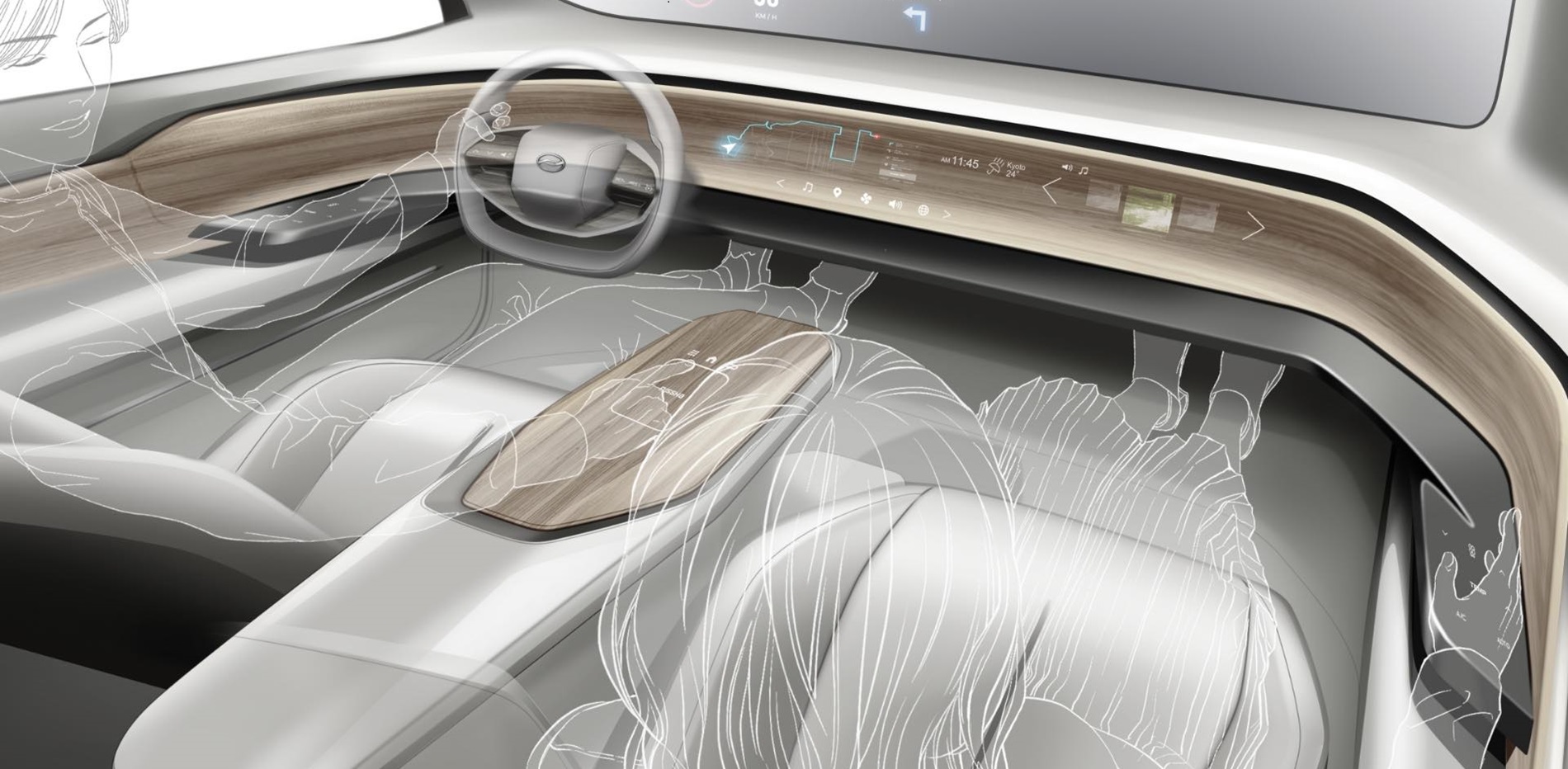

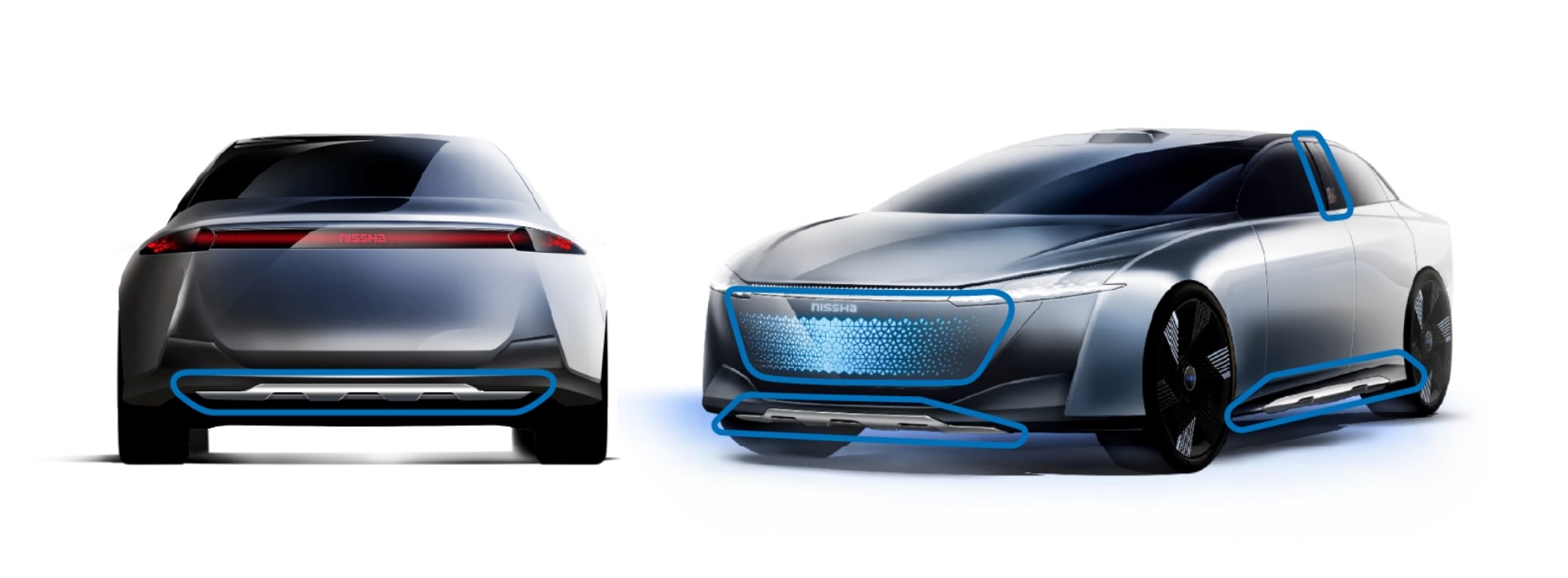

Until now, polypropylene (PP) has not been used in visible areas of automotive interiors and exteriors because it is difficult to paint or plate and its appearance quality is inferior to PC/PC-ABS. However, Nissha’s technology has made it possible to apply various designs and functions to the surface of polypropylene (PP).

By using Nissha’s technology to apply IMD (In Mold Decoration) or IML (In Mold Labeling) to PP, it is possible to achieve a premium appearance without paint. This allows for a wide range of finishes—matte/low-gloss, soft-touch, wood-grain, metallic, and even light-transmitting designs for automotive lighting or display areas—while also contributing to CO₂ reduction compared to painting.

Automotive applications of polypropylene

Automotive Interior — door trims, center consoles, instrument panels and fascias, pillar garnishes, glove boxes, seat-back shells,luggage-area trims. PP enables low-gloss, soft-touch, wood-grain, or metallic looks without paint when paired with a polypropylene decorative film.

Automotive Exterior — B-pillar appliqués, mirror caps, roof and door moldings, wheel-arch and bumper trims,exterior garnishes using PP-rich TPOs. Weatherable grades and proper edge-sealing allow durable outdoor performance.

Using PP for both the substrate and the surface keeps the construction within the same material family, supporting monomaterialization and improving automotive end-of-life sorting and recyclability. This approach can be applied to virgin PP, recycled PP, and biocomposites.

In particular, recycled PP often has poor appearance quality when molded with impurities such as paint residues. However, by decorating with polypropylene decorative film, these impurities can be concealed, thereby improving the appearance quality. Additionally, it is possible to add shapes and designs that take advantage of the unique textures of biocomposites in automotive interiors and exteriors. (Regulatory compliance, such as ELV, is validated at the part/OEM level.)

Nissha polypropylene decorative film lineup for automotive

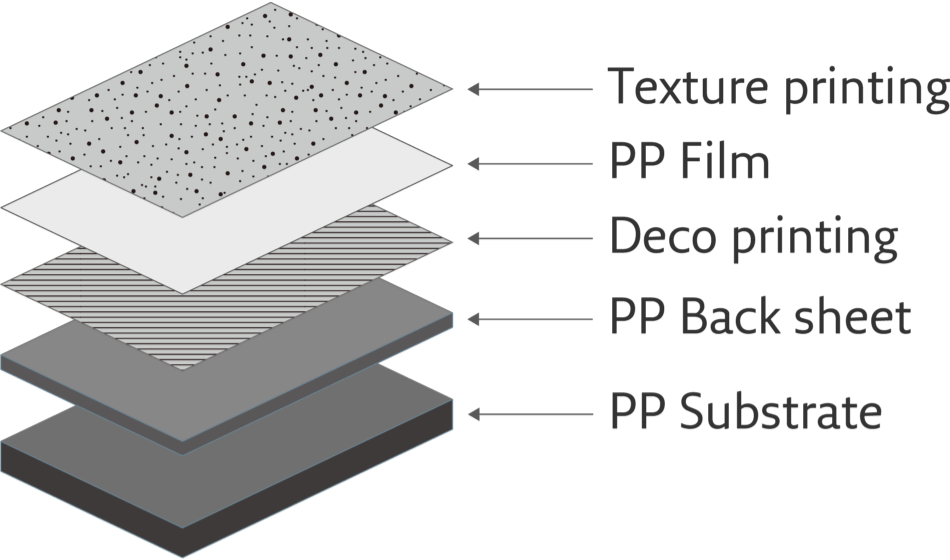

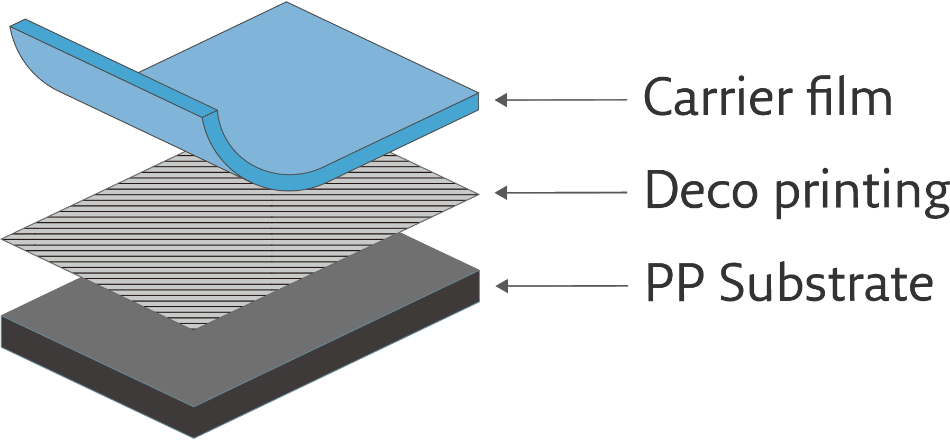

Nissha introduces the following polypropylene (PP) decorative film solutions for automotive applications. Product documentation such as material declarations can be provided on request.

| Type-P for Deep Drawing Shapes | Type-P Composed Solely of PP | Type-TR with Ink Transferred Only onto PP Resin |

|---|---|---|

|  |  |

|

|

|

Want detailed material data or design possibilities?

Contact us anytime