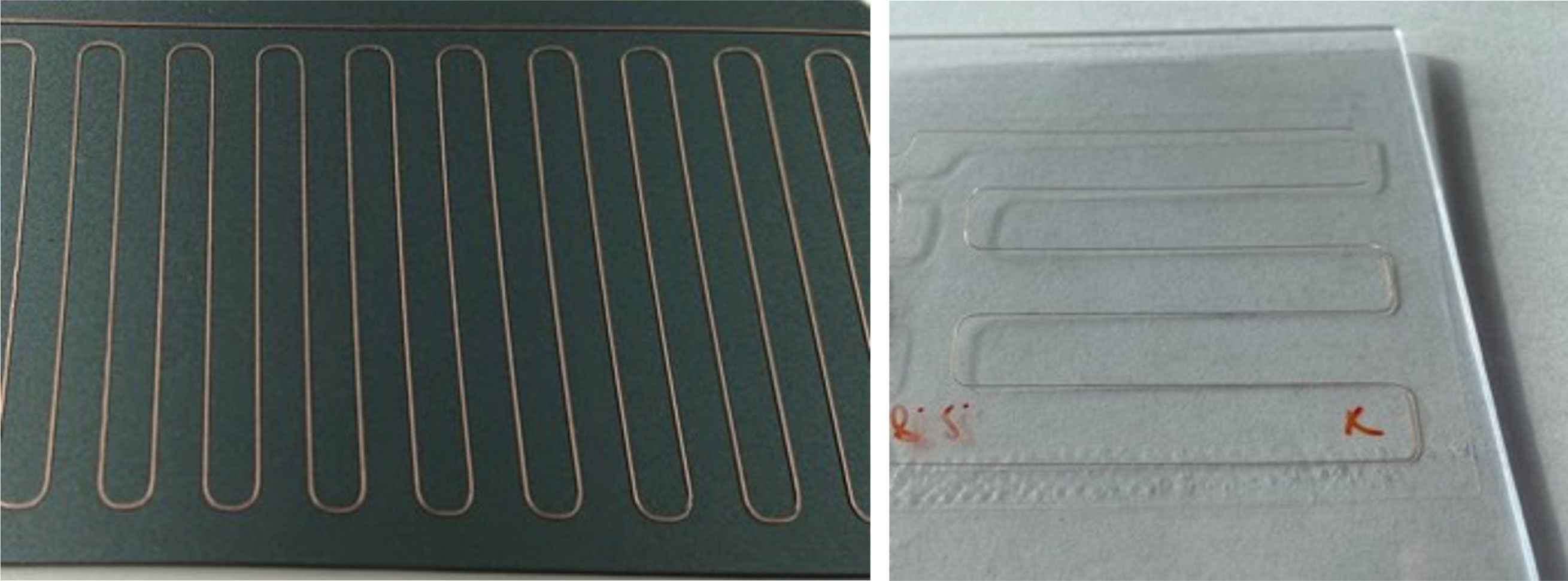

Incorporating film heaters

into automotive exterior plastic components

Anti-fogging and de-icing heaters

to maintain the functionality of LiDAR and Sensors

Wire-embedded film heaters

• Wire-pattern design that ensures radio-wave transparency

• One-stop processing that includes incorporation into molded products

• Ability to accommodate IMD/IML (in-mold decoration)

We can propose designs for customers.

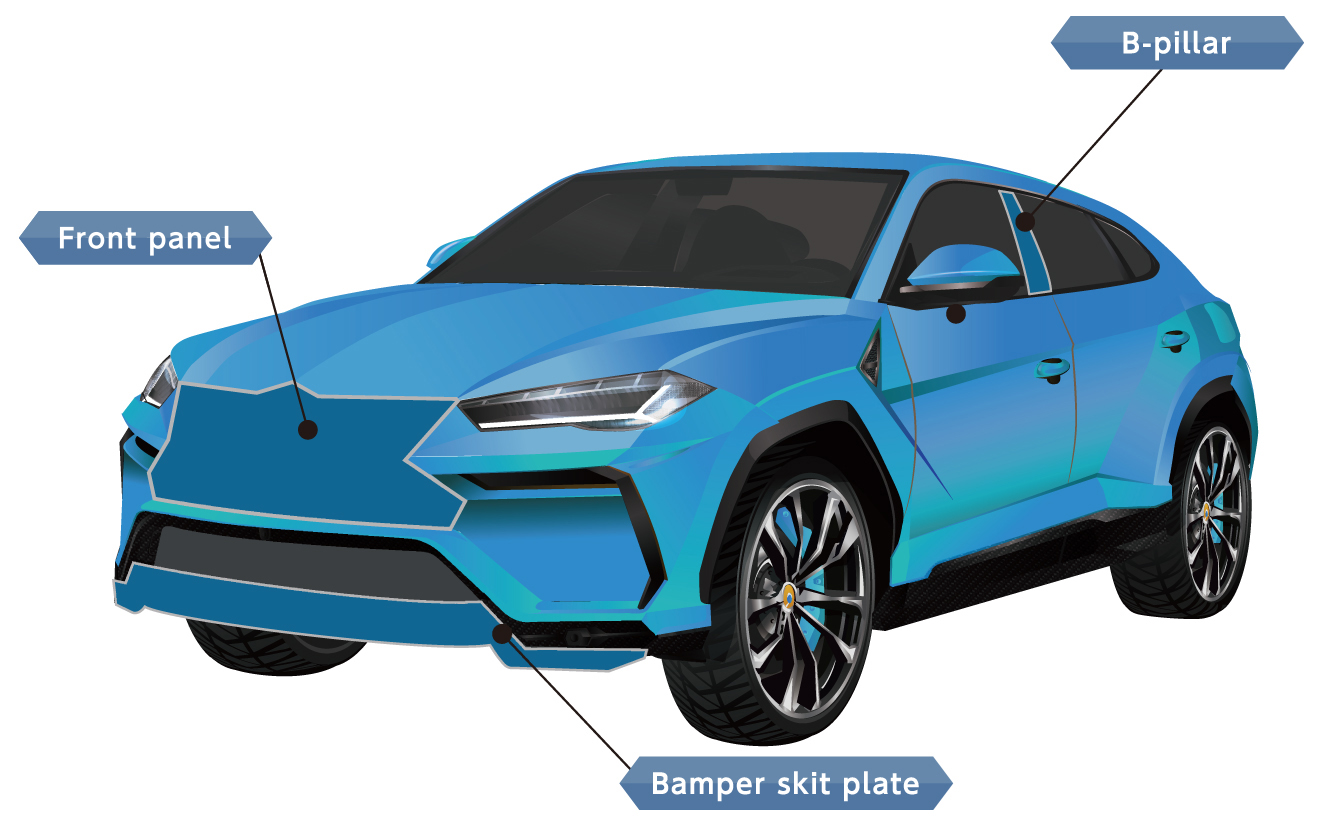

Product form that allows for development

– Heater and decorative film

– Heater and decorative film and molded component

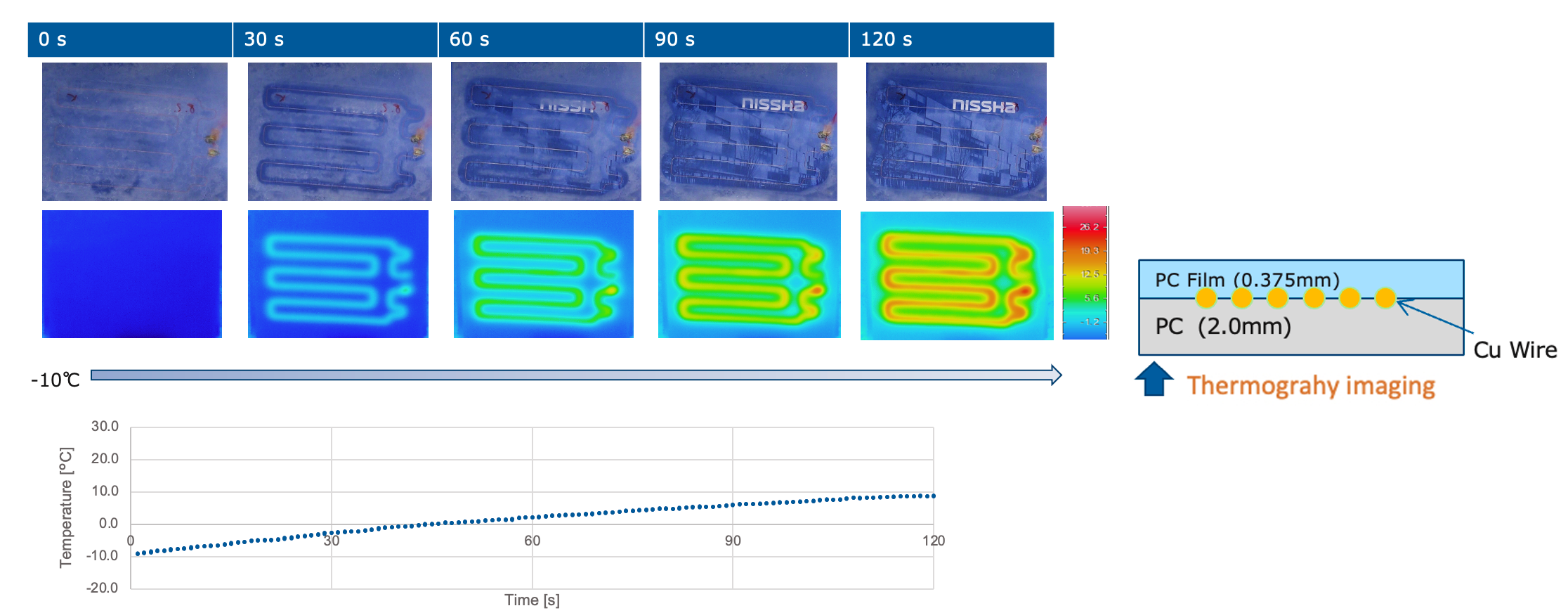

Data from defrosting testing

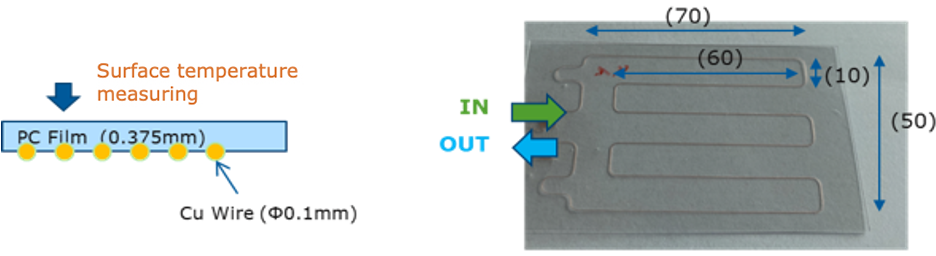

Sample configuration

Formation of heater (wire) on top of PC film

Sample size of 70 × 50 mm

Evaluation of heating characteristics from PC film side

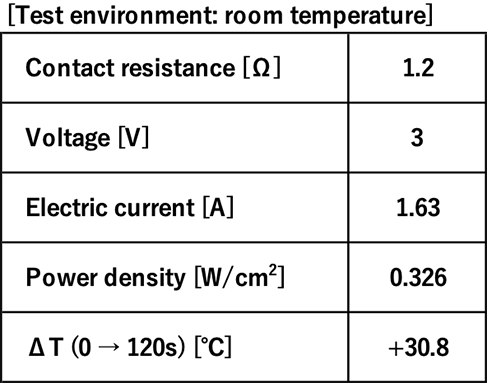

Electrical characteristics and heating characteristics

When 3 V is applied in a room-temperature environment, the temperature of the surface 120 seconds later undergoes a change of +30.8 °C.

This heating performance melts snow and frost in cold regions.

At the same time that the power of the heater is turned on, the temperature of the wire portion rises, and defrosting fully takes place.

After 120 seconds, the temperature of the surface of the sample rises by approximately 20 °C.

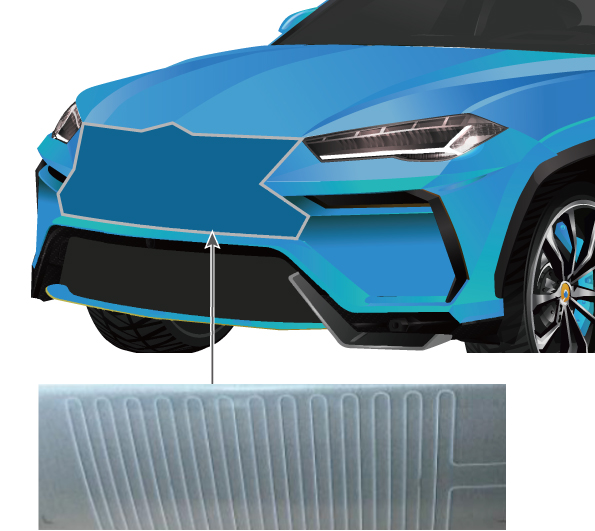

Example of adoption

Front panel with wire heater for electric vehicle (EV)

A Nissha film-insert-molded product into which wire is embedded has been adopted for an EV front panel that is equipped with LiDAR.

We ask for customers to not hesitate to consult Nissha about the development and manufacture of film heaters.

Feel free to contact us