-

① Weighing

The cosmetic ingredients are weighed.

-

② Mixing

The ingredients are mixed together by machine.

Dissolving Microneedle Patches

for Cosmetics

Manufacturing

Technology

and

Quality Control

Manufacturing Process

Dissolving microneedle patches for cosmetics are manufactured using high-precision molding technology.

1. Raw materials preparation

2. Molding

-

Filling

The mold tray is filled with mixed ingredients.

-

Drying

The tray is dried and gelled in an environment that will not damage the cosmetic ingredients.

-

Laminating

The adhesive sheet is laminated to the dried gel.

-

Die-cutting

The patch is punched out to the specific shape desired.

This video provides an overview of the molding process.

3. Packing and shipping

-

① Packin

The patches are packed into blister cases or aluminum pouches.

-

② Packaging and storage

The patches can then be packaged into presentation boxes if you desire, and stored in our warehouse.

-

③ Shipping

The product is shipped from our factory warehouse.

4. Product delivery

Sample Specifications

-

Application examples

-

Anti-wrinkle for eyes or smile lines / Spot care / Acne treatment / Etc.

-

Ingredients

-

Sodium hyaluronate, glycerin, water, etc.

-

Additional functional ingredients

-

As specified by customer

-

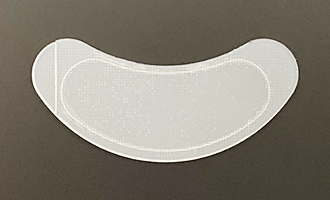

Patch shape

-

For eyes

/ For spot care

/ For spot care / Etc.

/ Etc.

-

Needle shape

-

Truncated cone with a flat tip*1

-

Needle length

-

140 μm*1

-

Needle density

-

400 needles/cm2 *1

-

Needle protection plate

-

Used*2

-

Packaging types

-

Blister case / Aluminum pouch / Presentation box

- *1) Basic specification recommended for efficacy and safety.

- *2) The fine dissolving needles are carefully protected by a plate until just before use.

We can customize the specifications,

so please let us know your wishes

using the Contact Us form below.

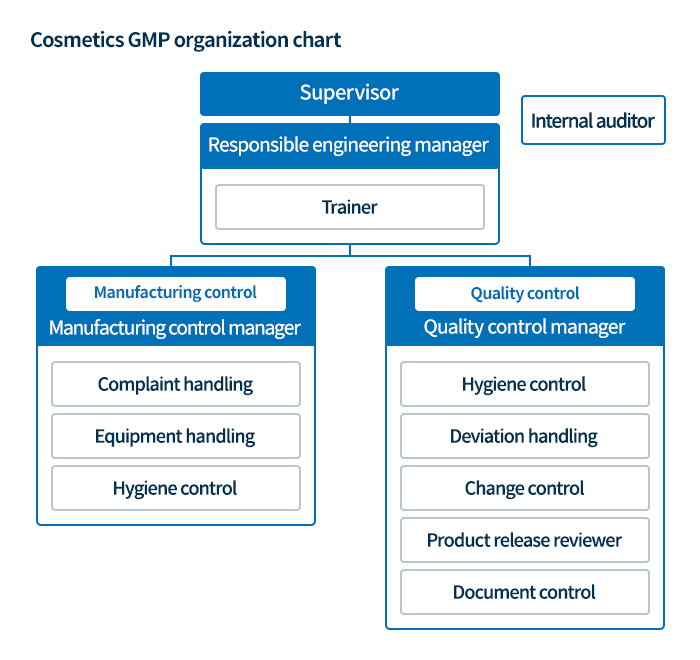

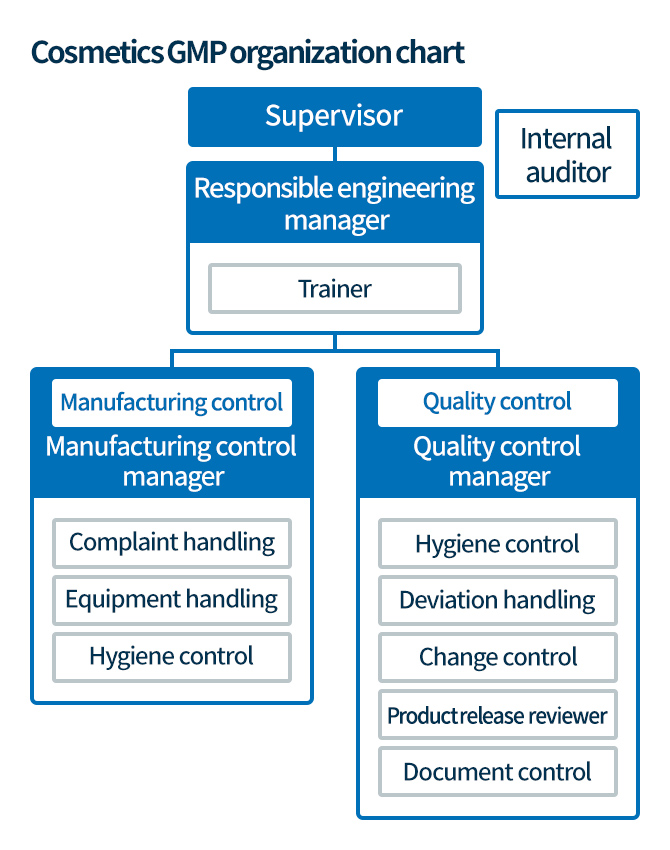

Quality Control System

All processes, including supplier selection, receiving raw materials and materials, manufacturing,

and shipping products are compliant with Cosmetics GMP.

- Raw materials/other materials acceptance test

- Acceptance tests for cosmetic raw materials and other materials.

- Process control

- Checks of manufacturing process and standard control range.

- Product inspection

- Property confirmation inspection, contents measurement, microbial test, etc.

- Document issue

- Issue test reports.

We also calibrate our equipment and devices.

Related Contents

-

Features of

Nissha Microneedle PatchThere you can learn about Nissha's microneedle patches for cosmetics.

-

Steps in

Outsourcing WorkThere you can learn about the steps in outsourcing work for OEM/ODM.

See the link below

for microneedle patches for cosmetics FAQs.

Inquiries

Please feel free to contact us

about the development or manufacture

of microneedle patches for cosmetics.