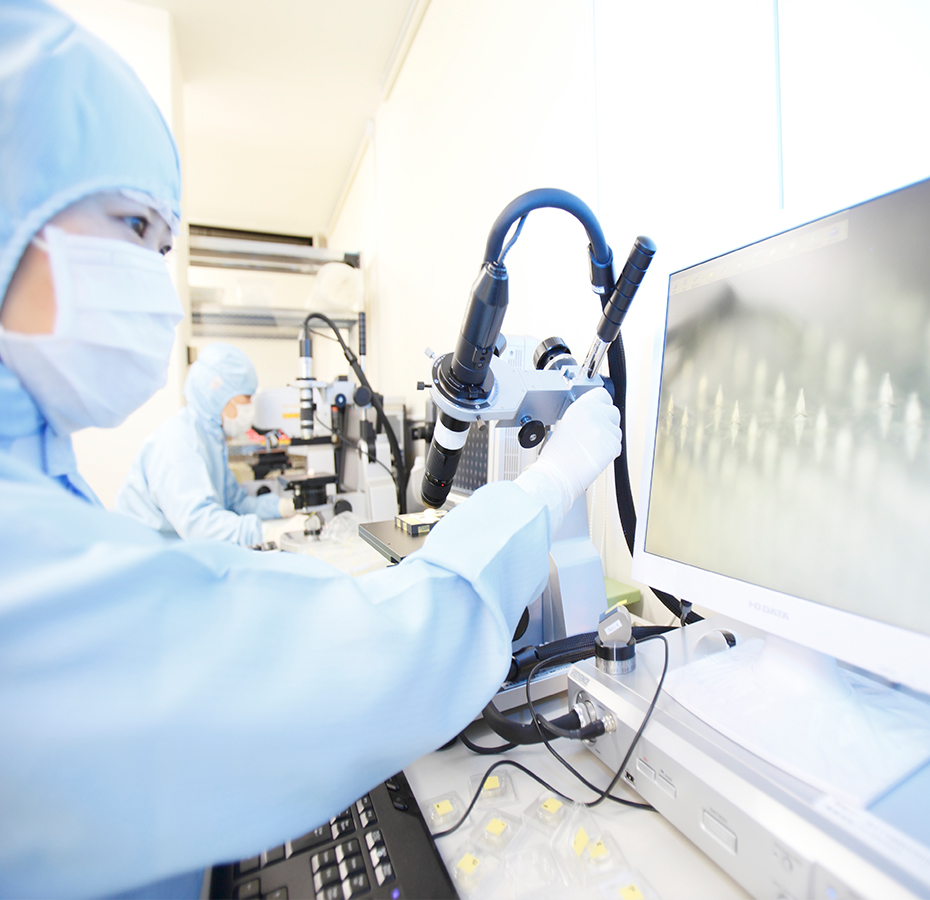

Advanced hygiene management through our cleanroom

Microneedle patches for cosmetics come into direct contact with human skin, and so must be manufactured in a clean environment.

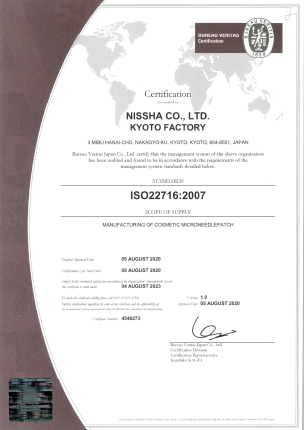

A number of different ways are used at Nissha's Kyoto Factory to create and maintain this clean environment. One of these ways is the Class 10,000 cleanroom at our factory, which meets strict hygiene standards.