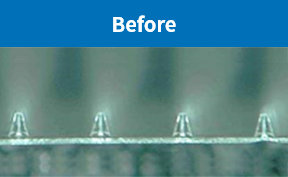

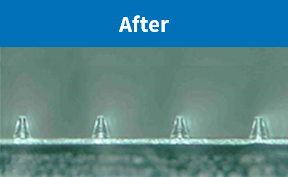

What is "Microneedle"?

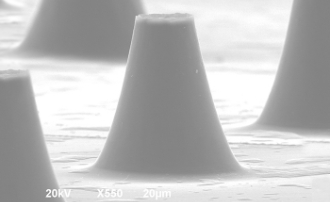

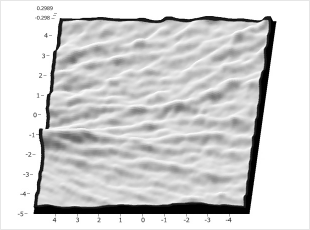

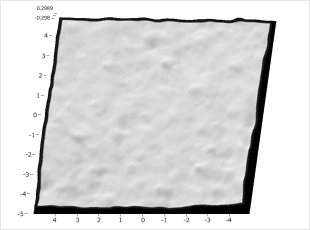

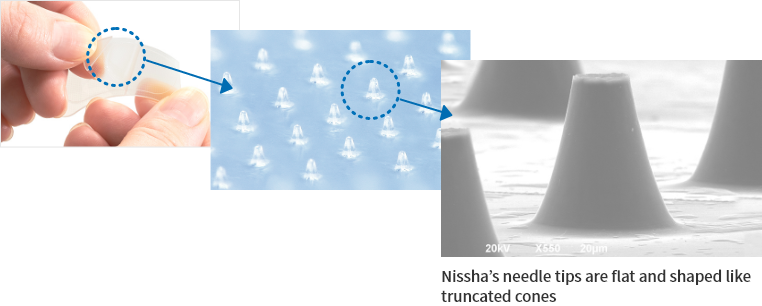

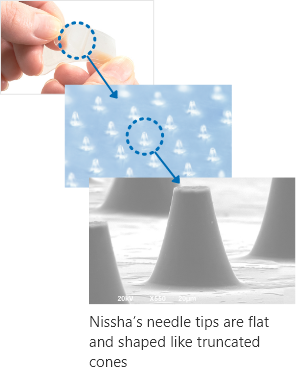

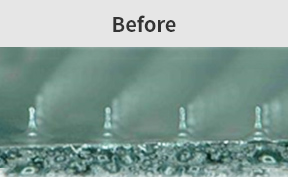

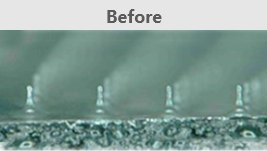

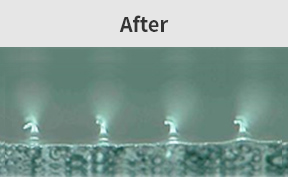

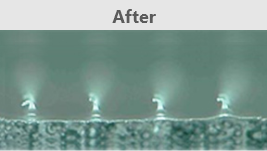

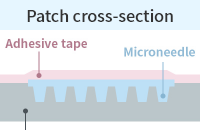

Our dissolving microneedle patches work to deliver the active ingredients directly into the skin. This is done by dissolving a large number of fine needles (microneedles) formed by drying and solidifying the active ingredients. It creates a DDS* using the latest technology, and is attracting attention from the pharmaceutical and medical industries.

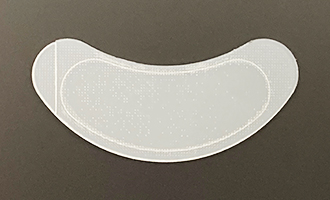

The dosage format that Nissha has developed to use this DDS for skincare cosmetics is the dissolving microneedle patch for cosmetics. The specific content of the dosage format and the mechanism until it exerts its efficacy as a cosmetic product are as follows.

*Drug Delivery System