Paint-alternative technology

Film insert molding for automotive exterior components

Why is alternative painting technology necessary?

Generally, automotive exterior components are decorated with the painting method.

Nevertheless, painting has issues like the ones below, so there is demand for an alternative method that can resolve such issues.

・Environmental impact and power consumption

In the case of the painting method, the processes of painting and drying are repeatedly carried out. Furthermore, paint processing requires relatively wide booths. As a result, concerns have been arising regarding environmental impact in relation to factors such as waste-liquid treatment, emission problems, heat emitted from drying, and power consumption.

・Diverse design

With painting, the entire vehicle body is generally made a single color. When giving vehicles special designs that include geometric patterns or lettering, etc., post-processing is required.

・Incorporation of electronic components

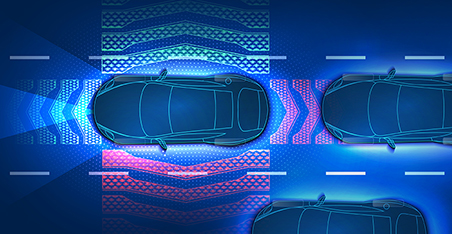

Due to the popularization of ADAS and so on, development has started for the incorporation of various sensors into exterior panels. Amid such development, painting has become a factor that can affect sensor performance. It is said that the use of metallic paints and unevenness in paint-film thickness can interfere with aspects of sensor performance such as radio-wave transparency.

Potential of film insert molding

We have developed processing technologies for automotive exterior panels with film insert molding, as alternative technologies for resolving the issues of the painting method.

The method of decoration with film insert molding has the following characteristics.

No. 1 Reduced environmental impact resulting from shortening of manufacturing process and elimination of drying processes

No. 2 Improved richness of designs

No. 3 Ability to carry out one-stop processing with incorporation of functional components into exterior panels

No drying process

Diverse designs

Functional components

incorporation

Characteristic 1Reduced environmental impact resulting from shortening of manufacturing process and elimination of drying processes

General painting process

Film insert molding process

Film insert molding is a processing method in which decorative films and molded products are integrated by using thermal pressure during the injection molding of plastic parts.

Since decoration is completed during the injection-molding stage, there is no need for large spaces such as painting booths, and there are no concerns with regard to waste liquid treatment. Furthermore, the processes of drying and recoating are eliminated, so a significant reduction in environmental impact can be expected.

We possess an integrated manufacturing process

that ranges from film printing to insert molding.

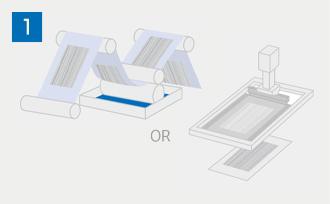

Printing

We are able to accommodate the process starting from the printing of decorative films.

Using multicolor gravure printing machines, we can create not only monochrome expressions, but also a diverse range of patterns that are achieved through the overprinting of various inks.

Film preforming

The films that have undergone printing are preformed through pressure forming.

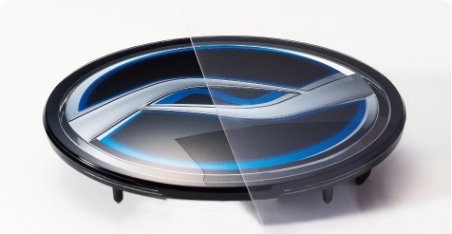

For the decorative films, olefin or acrylic films, which have outstanding stretchability, are used. This is to enable the films to be used for the deep shapes of items such as bumper guards and center-cap ornaments.

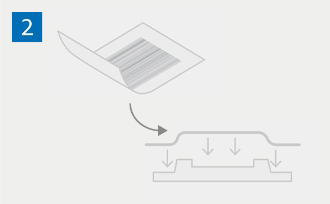

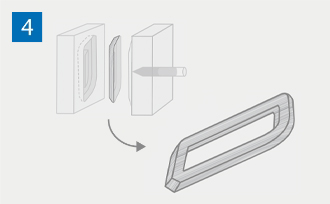

Film trimming

Following the preforming, the unnecessary portions of the film are trimmed in accordance with the size of the molded product, using a Thomson cutter or laser processing machine.

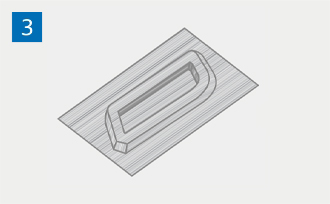

Film insert molding

The trimmed film is inserted into a mold, and insert molding is carried out.

During this process, the film is integrated with olefin resin, which is frequently used for exterior components, through the thermal pressure of injection molding.

We possess an integrated mass-production process that ranges from film printing in Japan to insert molding overseas. As a result of this, we are able to supply insert-molded products globally.

Also, we can accommodate supplying just films to a designated molding factory according to customers’ requests.

Characteristic 2Ability to accommodate diverse designs

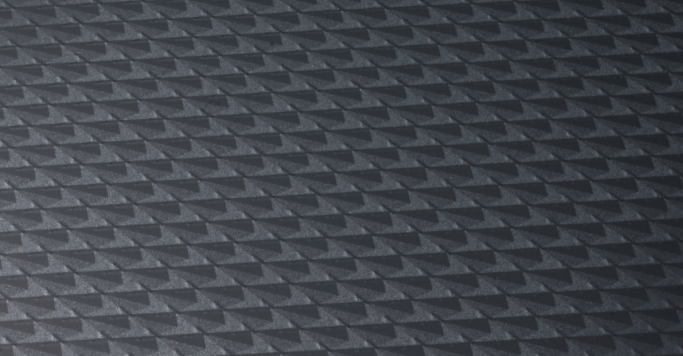

In the case of film insert molding, various designs can be realized that cannot be achieved through painting.

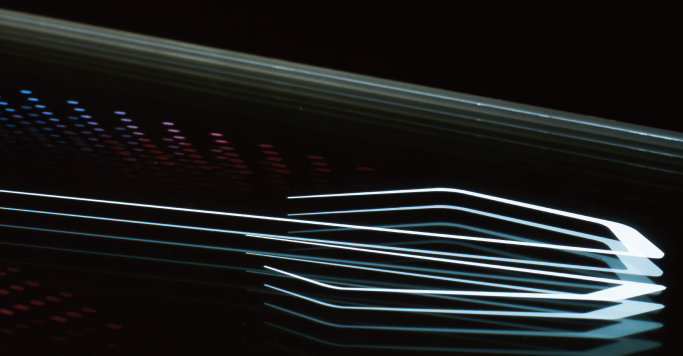

The possible designs go beyond monochrome expressions, and include metallic finishes, carbon fiber patterns, and geometric designs. Furthermore, on the back surface of molded products, it is possible to achieve hidden-lit designs that incorporate LED light sources.

Through our in-house CMF Design Team, we propose high-quality designs while listening to the requests of customers. We ask for customers to first of all let us know what they would like to do.

Carbon pattern

Hair line

Metallic color

Abstract pattern

Translucent light emittion

(Dead front)

Geometric pattern

Characteristic 3Ability to incorporation of functional components

We at Nissha have developed technologies for not only manufacturing decorative parts, but also incorporating electronic components into plastic molded products.

We have undertaken the challenge of not only bonding electronic components, but also insert molding electronic components, such as heaters and LED.

Our technologies thus make contributions in areas such as radio-wave transparency for ADAS sensors, the melting of snow, and development related to personal authentication and new entry functions.

radio-wave transparency

Learn more >

Touch screen

embedding

Heater embedding

Learn more >

IR-wave transparency

Film insert molding for large-scale components

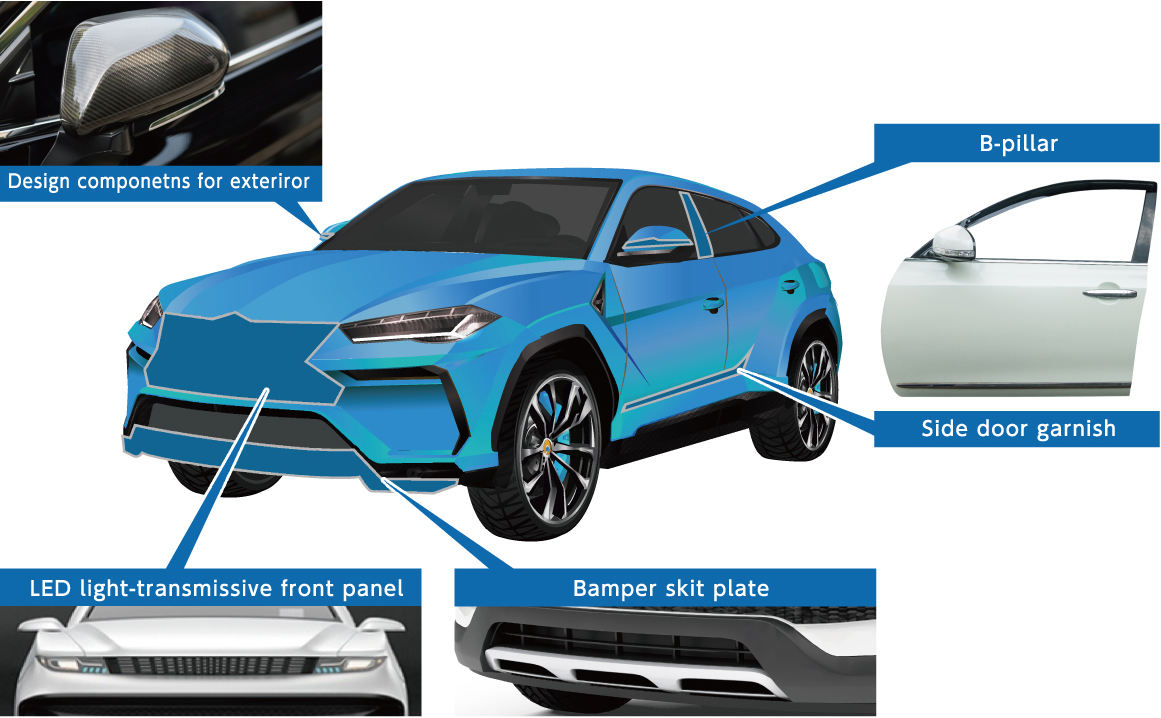

We can accommodate the film insert molding of large molded products for exteriors, such as bumper guards, door trims, and pillars.

We ask for customers to first of all let us know their requests.

Contract manufacturing with film insert molding

as a paint-alternative technology

We can accommodate the contract manufacturing of automotive components with film insert molding.

Film insert molding is a one-stop processing technology with the characteristics of “reduced environmental impact,” “outstanding richness of designs,” and “ability to incorporate functional components.”

We would thus like to encourage customers who considering adopting a new decoration technology to replace painting, to consider film insert molding.

Feel free to contact us