IMD = In Mold Decoration is the technology to apply versatile CMF finish onto 3D geometry plastic surface during injection molding.

This technology widely used in consumer electronics, appliance, automotive and medical/healthcare devices, and supports customer to achieve unique CMF finish on mechanical parts with high quality and productivity.

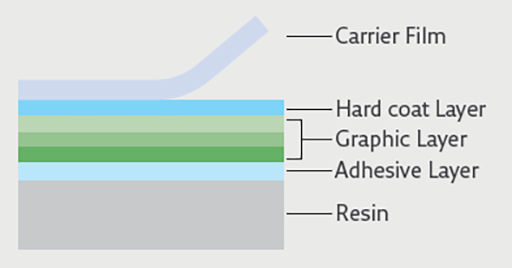

Nissha’s UV cured hard coat layer protect surface against scratch, chemical, UV irradiation without secondary process.

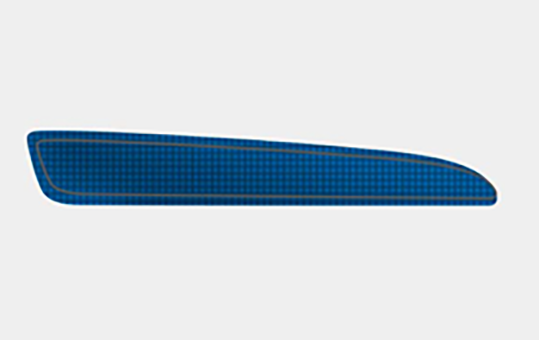

Since decoration is applied at the same time of injection molding process, surface decoration follow 3D geometry.

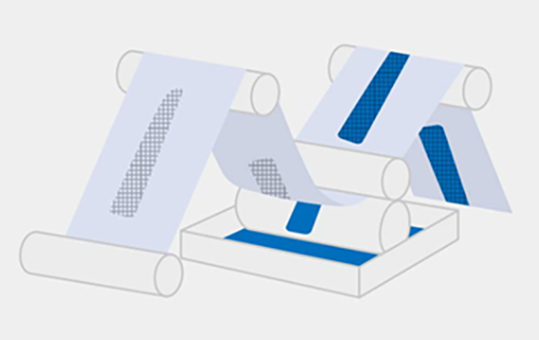

Nissha foil feeding system contorlled by optical sensor enables precise registration within+/-0.25mm.

Film printing and IMD molding is managed by roll to roll system. Its production is automated and efficient.

Thin IML ink is only applied to the area where decoration is needed. Volatile organic compounds can be reduced.

NISSHA’s IMD works well with capacitive touch sensor, no harm on its sensitivity

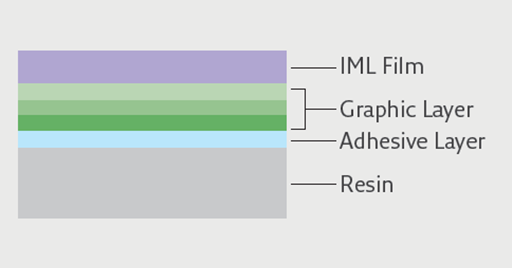

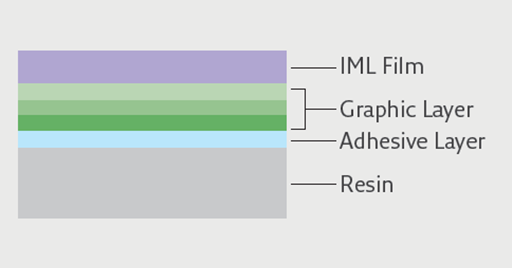

Composition

IMD is a simple and productive process. Decoration is done inside of the tooling without any pre / secondary process, and the whole process is controlled by a roll to roll system. Decoration is completed, including hard coat protection, with just a single shot molding.

IMD film is printed by high speed gravure printing process.

7 layers of graphic color (max) plus also hard coat layer and adhesion layer are applied during this printing process.

A foil feeder is installed on the injection machine. IMD film is then fed between the injection molding tool. Optical sensors in the feeder adjust registration of the film, and the ink printed on the film is transferred onto the plastic by the heat and pressure of injection molding.

After injection molding, you have complete decorated products. No secondary process is necessary. (only UV curing for hard coat)

Depth / Multi layer effect

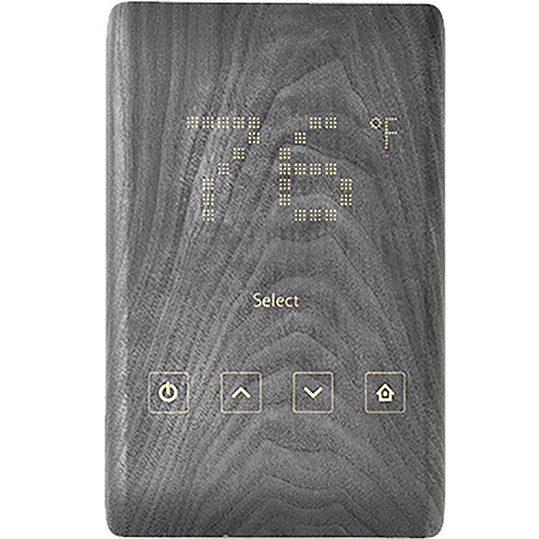

Hidden til lit

Brushed Hair Line

Gradation

Marble stone

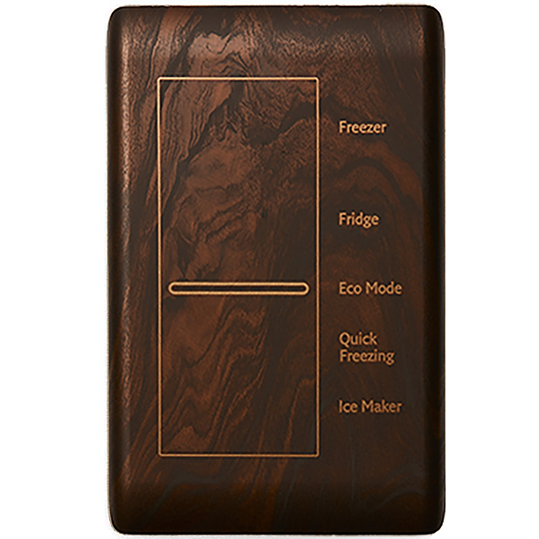

Wood grain

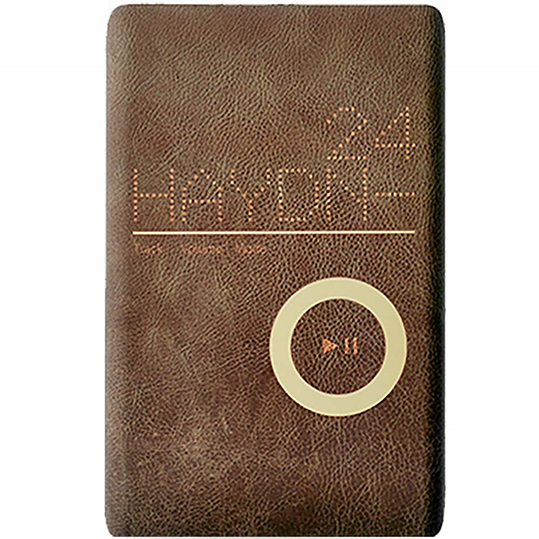

Leather

Fabric texture

IML = In Mold Labeling is the technology to apply printed and pre-formed film onto 3D geometry plastic surface where film and plastic are merged (mixed?, adhered?) during injection molding.

This technology is especially suitable for decorating deep and complex shape. Furthermore, because of surface IML film layer, a high-quality exterior with a sense of depth and robust physical properties are available.

Dedicated forming process prior to injection molding forms IML film deep draw and complicated geometry.

Graphic layer is fully protected from abrasion by IML film. Additional functionalities like UV or chemical resistance is available by special films.

Thin IML ink is only applied to the area where decoration is needed. Volatile organic compounds can be reduced.

Nissha range of printing methods allows flexible manufacturing. Silk-screen printing for lower volume production, Gravure printing for higher volume production.

Unique coating and printing technology can create excellent natural finishes including tactile texture, effects like stainless steel, natural wood, and fabric-like patterns.

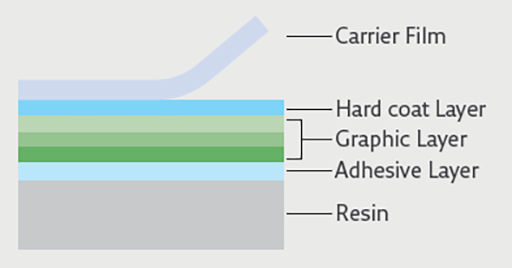

Composition

IML process consists of multiple steps – printing, forming, trimming and molding.

Because of the dedicated forming process, IML process is well suited for deeper draw parts and complicated geometries.

Also, since the carrier film remains on the surface with the IML process, a high-quality exterior with excellent physical properties and a sense of depth can be achieved.

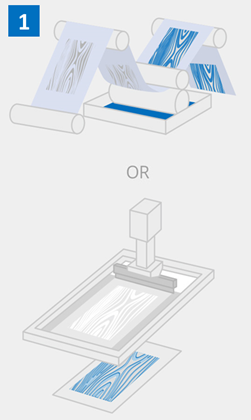

Printing

For IML film, Nissha has two printing methods – Gravure printing and Silk screen printing. Depending on design specification and production volume, the best printing method is chosen.

Forming and Trimming

IML film is set in the forming machine and formed into the geometry of the part’s shape by high heat or high pressure. Then the periphery film is trimmed by die cut machine or laser.

IML molding

Formed IML film is inserted into the injection molding tool and combined with resin.

Product

After injection molding, the result is finished decorated products.

| IMD | IML | |

|---|---|---|

| Layer structure |  |

|

| Film | Released | Remain |

| Remain | Roll to Roll | Sheet |

| Process | Simple (Just Molding) | Multiple (Forming / Trimming / Molding) |

| Geometry | Shallow | Flexible (Sharp, Deep) |

| Volume | Middle – High volume | Low – Middle volume |

Please feel free to contact us.

CLICK