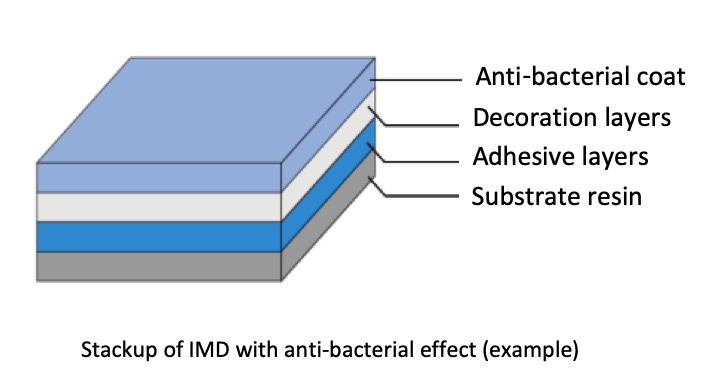

It is not only decorations that can be applied by NISSHA IMD; a functional layer with an anti-bacterial property can be applied as well. Our IMD with anti-bacterial effect achieves clean, safe user interface.

●Anti-bacterial layer only on top surface, where the property is needed

By insert molding a decoration film with anti-bacterial coat, the property can be applied only on the top surface.

In comparison with a process which uses resin blended with anti-bacterial agents, our process requires less amount of agents, which leads to a reduced cost.

The anti-bacterial agents are made from inorganic matter and harmless to humans.

●No extra processes to add the property

As the anti-bacterial layer is applied simultaneously with the decorations, no additional process is required to get the property.

●Additional effects of hard coat and anti-fingerprints

NISSHA IMD can even add effects of hard coat and anti-fingerprints simultaneously with the anti-bacterial effect.

●A clear layer that does not affect the cosmetics

Anti-bacterial agents tend to have low transparency and can sometimes affect the cosmetics of products.

NISSHA IMD with anti-bacterial effect has a highly transparent layer of anti-bacterial coat, which keeps the original cosmetic quality.

●Available for heat transfer foils as well

Anti-bacterial effect is not limited to the application on IMD products.

It is available for general heat transfer foils as well.

We propose the most suitable solution depending on applications of your products.

| Escherichia coli | Staphylococcus aureus | ||

|---|---|---|---|

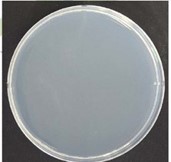

| *3 Nissha hard coat + bacterial effect IMD |

Bacteria cultivated for 24h |  |

|

| *2 Value of antimicrobial activity[Ut – At] |

5.9 | 4.1 | |

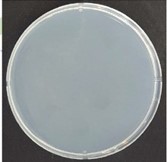

| Nissha Anti-fingerprint hard coat + anti-bacterial effect IMD |

Bacteria cultivated for 24h |  |

|

| Value of antimicrobial activity[Ut – At] | 5.3 | 5.3 | |

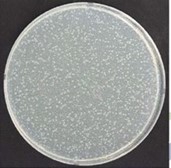

| Nissha anti-bacterial effect heat transfer foil | Bacteria cultivated for 24h |  |

|

| Value of antimicrobial activity[Ut – At] | 5.9 | 4.1 | |

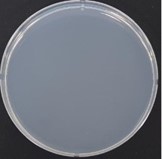

| Non anti-bacterial effect sample | Bacteria cultivated for 24h |  |

|

| Value of antimicrobial activity[Ut – At] | – | – | |

*1 Drop 0.4ml of inoculum on a test piece (5cm×5cm) placed in a petri dish. Cover it with a piece of film (4cm×4cm), place the lid of petri dish, and incubate it at a temperature of 35±1°C and a relative humidity of not less than 90% for 24±1h. Place the covering film and the test piece in a stomacher pouch, add 10 ml of the SCDLP broth and wash out the bacteria. Count the bacteria by the agar plate culture method and calculate the value of antimicrobial activity.

*2 Value of antimicrobial activity = log (the number of viable cells of bacteria after incubation, per 1cm2 of untreated test piece) – log (the number of viable cells of bacteria after incubation, per 1cm2 of antimicrobial test piece)

Anti-bacterial effect is proven when: : the value of antimicrobial activity ≧ 2.0

(This means the number of viable cells of bacteria in the antimicrobial test piece is 1% or less of that of untreated test piece.)

*3 hard coat

As the effects of hard coat and anti-fingerprints can be added to NISSHA IMD with anti-bacterial effect, product surfaces with high performance in physical properties and anti-bacterial effect is achievable.

Even in comparison with our conventional anti-fingerprint hard coat, its durability does not drop.

*For in-vehicle use, it’s in the development study stage.

| Properties | Evaluation items | Anti-fingerprint hard coat + anti-bacterial effect | Conventional anti-fingerprint hard coat | |

| Transparency | Haze | 2.9% (PET/release ink layer/HC) |

2.7% (PET/release ink layer/HC) |

|

| Adhesion | Cross-cut adhesion | Pass | Pass | |

| Cross-cut adhesion after temp/humidity cycle test |

Pass | Pass | ||

| Hard coat | Pencil hardness (750g weight) | 2H (Substrate: PMMA) |

2H (Substrate: PMMA) |

|

| RCA abrasion (175g weight × 50 times) | Pass | Pass | ||

| Chemical resistance | Hand cream | Pass | Pass | |

| Fingerprint resistance | Contact angle (oleic acid) | 13.4° | 13.4° | |

| Anti-bacterial effect | Antimicrobial test(JIS Z2801) | Escherichia coli | ○ (Antimicrobial activity value: 6.4) |

– |

| Staphylococcus aureus | ○ (Antimicrobial activity value: 5.3) |

– | ||

●Laptops

●Home Appliances

●Stationery

Please feel free to contact us.

CLICK