Blog

Life Cycle Assessment (LCA) and Carbon Footprint (CFP)

– Part 2: Case Study: Introducing the CFP of Sulapac

2024/04/12

This blog is divided into two parts. Please see Part 1 here.

In Part 1, we explained what “Life Cycle Assessment (LCA)” and “Carbon Footprint (CFP)” are, their characteristics, differences, implementation procedures, and points to note.

In Part 2, we will introduce the “Carbon Footprint (CFP)” using Sulapac® , a biocomposite material handled by NISSHA, as an example.

What is Sulapac®?

Sulapac® is a bio-composite material that NISSHA handles. The main ingredients are wood chips, which are renewable resources, and plant-based binders. It is composed of up to 100% bio-based materials.

Sulapac® has various material grades, but the basic grades are the following two types using wood chips of different sizes. The wood chips use wood from managed forests in Northern Europe and by-products of industry and agriculture.

Universal: Uses fine wood chips

Premium: Uses coarse wood chips

Carbon Footprint (CFP) of Sulapac®

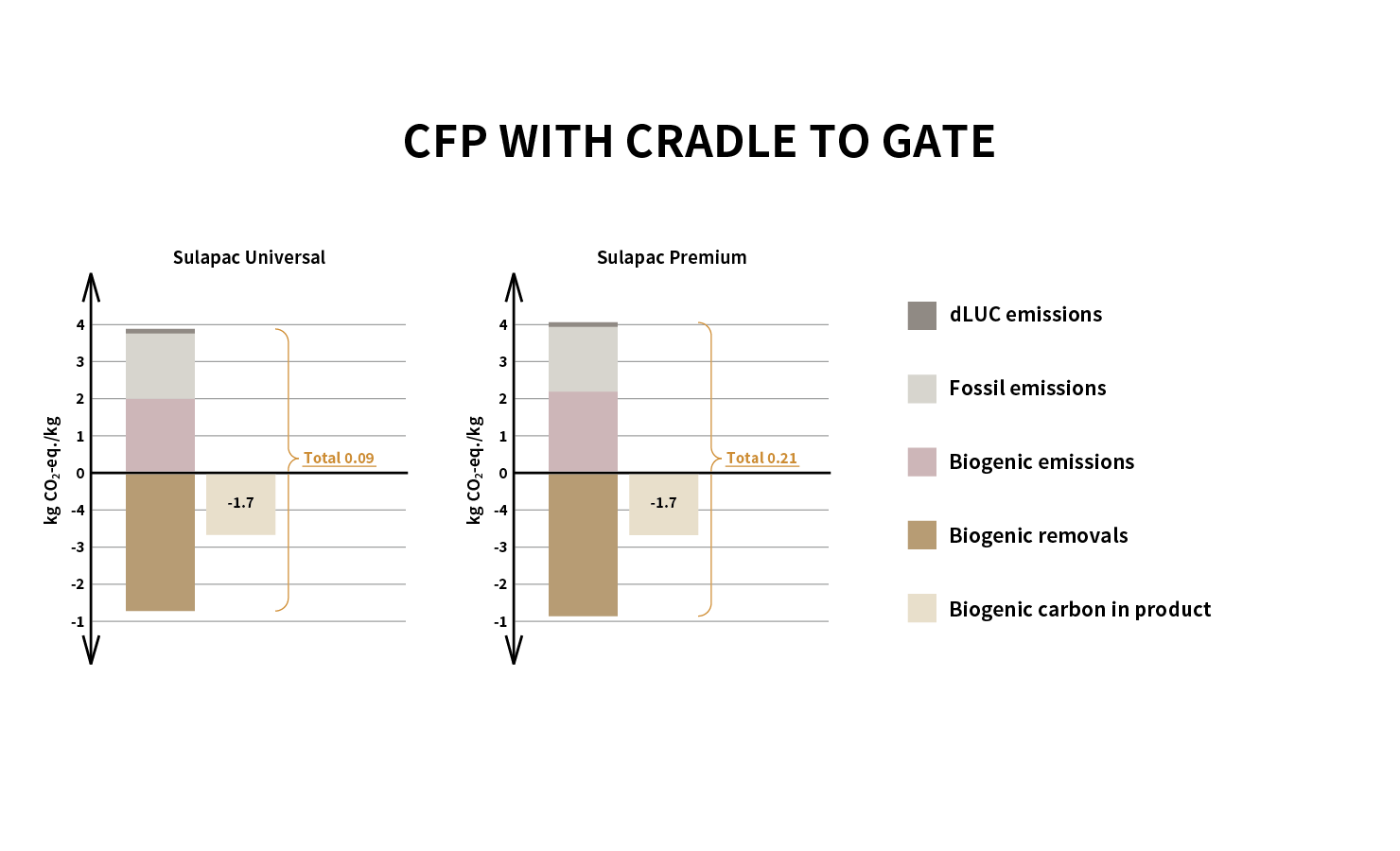

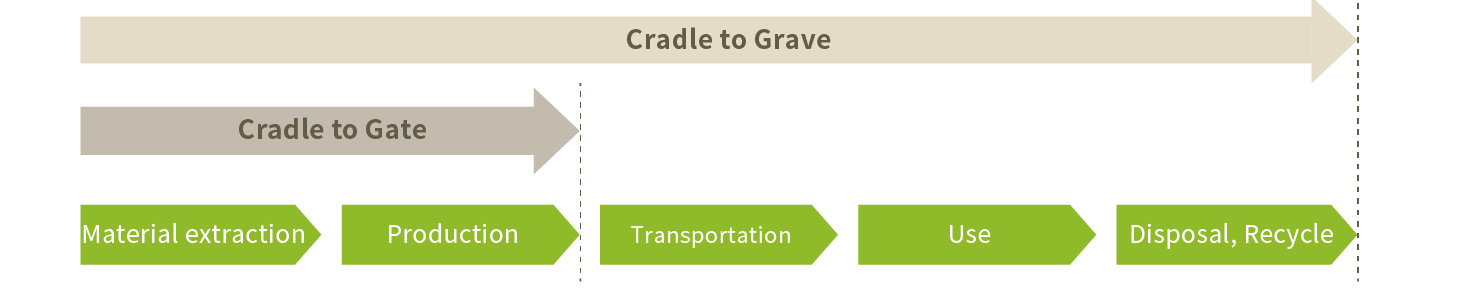

We have actually calculated the Carbon Footprint (CFP)※1 of Sulapac® Universal and Premium. The calculation range of the CFP is “Cradle to Gate※2”, and we are evaluating the CO₂eq.kg※3 per kg of raw material.

※1 For CFP, ※2 Cradle to Gate, please refer to Part 1 for explanation. Click here for Part 1

※3 CO₂eq stands for “CO₂ equivalent”, which is a value converted to CO₂ equivalent using the global warming potential (GWP). Million t-CO₂eq means million tons of carbon dioxide equivalent.

This calculation was performed by the consulting company “LCA Consulting” and has been critically reviewed by Sulapac. It has been conducted in compliance with ISO 14067:2018, ISO 14040:2006 and 14044:2006.

Calculation Results of CFP

As a result of the calculation of the CFP of Sulapac®, Sulapac Universal was calculated to be 0.09kgCO₂eq./kg, and Sulapac Premium was calculated to be 0.21kg CO₂eq./kg.* The calculation results are as shown in the table below.

*Sulapac,Reduce your carbon footprint with Sulapac

Since Sulapac® uses bio-based materials, the plants that are the raw materials absorb CO₂ through photosynthesis (Biogenic removals).Therefore, the amount of CO₂ emissions is low.

On the other hand, petroleum-derived raw materials do not absorb CO₂ from the atmosphere, so they tend to have higher CO₂ emissions. From this, it is important to recognize what kind of raw material the CO₂ originated from.

Units in the figure

*There are various theories about the interpretation of units.

- dLUC emissions

- This represents the greenhouse gas emissions due to changes in land use, such as when crops grown on a certain land are replaced with new crops. In the case of Sulapac®, it is mainly calculated based on the cultivation of the plants that are the main raw materials.

- Fossil emissions

- This is a general term for greenhouse gases released by the use of fossil fuels.

- Biogenic emissions

- This refers to CO₂ released by plants and organisms through processes such as respiration and decomposition. Also, CO₂ emissions at the time of biomass energy use are classified as biogenic emissions. In the method of ISO 14067, it is required to report “biogenic emissions” and “biogenic removals” separately, so they are displayed separately on the graph.

- Biogenic carbon in product

- This refers to the amount of CO₂ absorbed from the atmosphere by plants.

- Biogenic removals

- This refers to the carbon derived from organisms such as plants and animals contained in the product when plant-derived raw materials are used in the product.

Contributions to the Environment Outside of CFP

As mentioned in Part 1, LCA and CFP are important evaluation methods for environmental impact, but they are not the only indicators. Other environmental issues such as littering, microplastic problems, and marine pollution also need to be considered.

From here, we introduce how Sulapac® can contribute to the environment outside of CFP.

-

- 1. Use of Bio-based Raw Materials

-

- Use of Renewable Materials

- Petroleum-based raw materials are derived from organic matter buried underground that has decomposed and changed over millions of years. Therefore, they are not immediately regenerated after extraction and realistically exist only in limited quantities. In contrast, bio-based raw materials are primarily made from plants. Plants grow using sunlight and CO₂ and can regenerate in a short period, hence they are considered renewable.The wood chips of Sulapac® are made from timber from managed forests in Northern Europe.

- Waste Reduction

- The main ingredient of Sulapac®, wood chips, is collected from industrial and agricultural by-products, contributing to waste reduction.

- Environmental Pollution Control

- When using petroleum-based materials, there are concerns about ecosystem destruction due to risks (such as oil spills and permanent pollution) in the process of oil drilling and hydraulic fracturing. Sulapac® is composed of up to 100% bio-based materials.

-

- 2. Impact at Recycling

- Sulapac® is a recyclable material through mechanical recycling*, chemical recycling*, and industrial composting.

*According to Sulapac research. Varies by municipality.

-

- 3. Microplastics

- Microplastics are detected even in the ash from burning conventional petroleum-based plastics. If this ash is landfilled or used in recycled products, it is said that the remnants of microplastics could have harmful effects. Sulapac® is biodegradable, leaving no microplastics in the natural environment.

The biodegradability of Sulapac® is as follows:

- Complies with EN13432 (European composting standard), ASTM D6400 (composting test of products)

- Based on ASTM D6691 (measurement of aerobic biodegradation of plastic materials exposed to seawater)

- Verified to biodegrade 48%-59% within 280 days

Summary

In the future, it is expected that products using various environmentally friendly materials will expand. However, LCA and CFP, which can quantitatively and objectively demonstrate “environmental friendliness,” are expected to become increasingly important.

However, as mentioned in Part 1, accurately calculating LCA and CFP is difficult, and the entire supply chain needs to recognize its importance and act.

At NISSHA, we recognize the need to evaluate using LCA and CFP in methods other than Sulapac®