PaperFoam®

Foam Molded Products -

Lightweight and Cushioning

- Foam molding of pulp and starch

- Lightweight but high cushioning properties

- Securely fix products or components

- Lightweight compared to plastic

(specific gravity: approx. 0.2) - Extensive design freedom in shape achieved through molding process

- Various colors, textures, embossing options

- Recyclable as paper*

*It depends on the regulations and guidelines of each country or region.

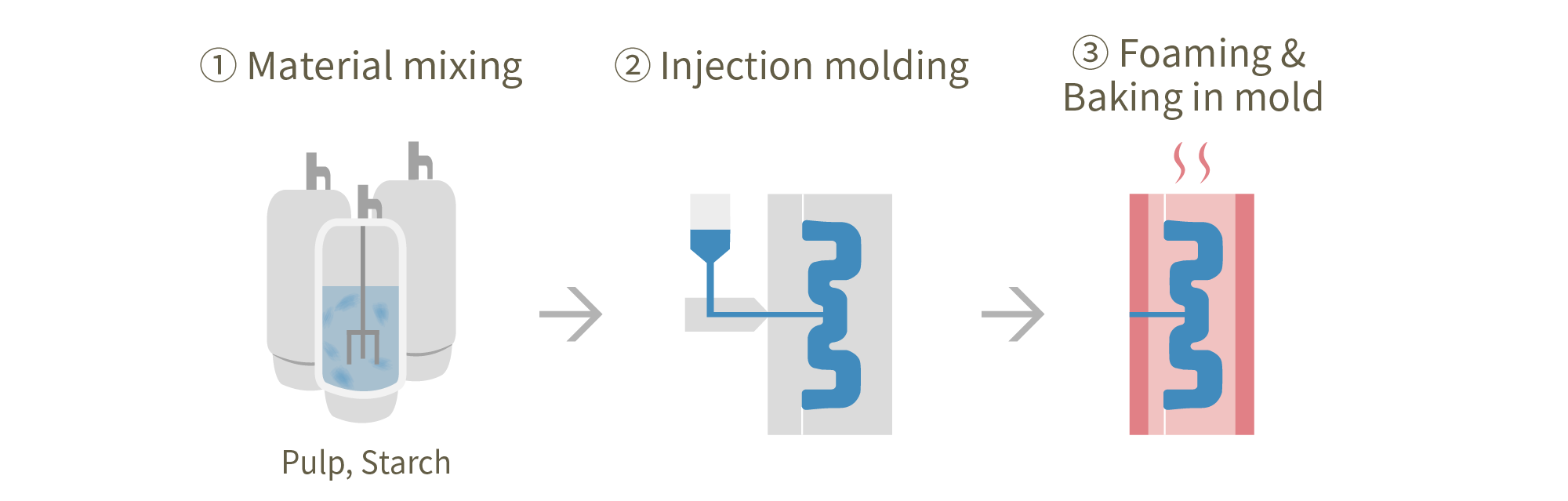

Process

- The main ingredients, starch and pulp, are mixed with water and injected into the mold.

- Heat is applied simultaneously during molding to cause foaming and create a 3D shape.

- At the same time, the moisture inside the material is evaporated, drying the product and completing the manufacturing process.

Key Features

- Lightweight and Cushioning properties

- PaperFoam® has excellent cushioning properties due to its foaming process. Additionally, its lightweight material properties (specific gravity is approx. 0.2) contribute to total weight reduction of packaging.

- Securely fix products or components

- Thanks to the molding process, PaperFoam® is capable of taking on a shape that perfectly fits to the product, providing a secure fit and effectively safeguarding it against shakings and vibrations during transportation.

- Precise dimensional accuracy

- It is possible to design an integrated tray by combining several packaging parts made of PaperFoam®, such as the lid and body, thanks to its precise dimensional accuracy.

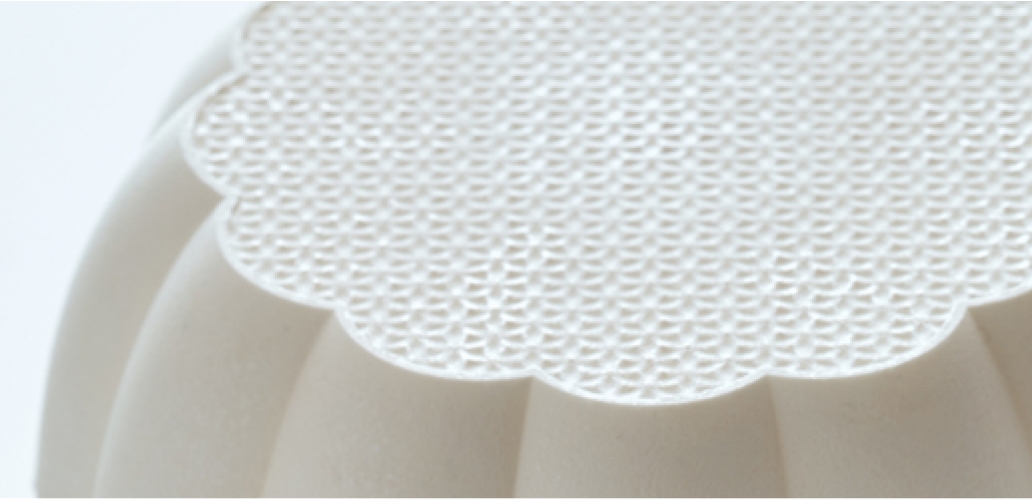

- Customized textures and colors

- Products can be colored, textured and embossed in a wide range of designs.

Applications

-

Mobile battery

case -

Cosmetics

Set box inner tray -

CPG (Earplug)

Inner tray

Certification

TUV Austria OK biobased (4 stars)

TUV Austria OK compost Home & Industrial

UL Validated: 99% recovery rate of available fibers

Specification

| Max. parts size(mm) | 200 × 300 × 150 |

|---|

| Parts thickness(mm) | 2.2 〜 3.0 |

|---|

| Minimum radius(mm) | 2.0 |

|---|

| Typical production volume (annually)(pcs) | 100,000 〜 |

|---|