Pulp-Injection

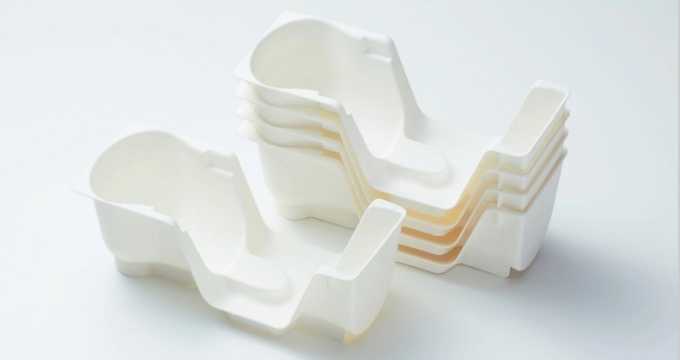

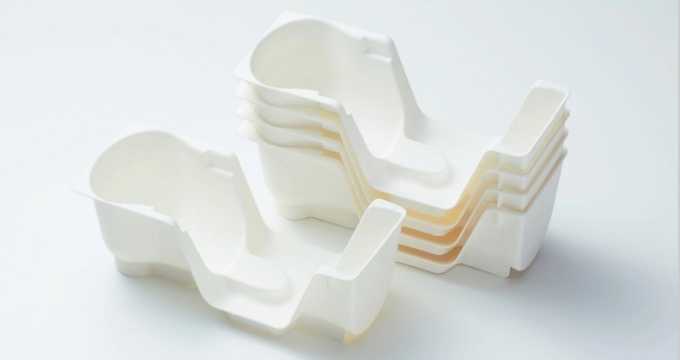

Injection Molded Pulp – Achieving Precision, Thinness, and Rigidity

- Environmentally friendly injection molded products made from pulp and starch

- Extensive design freedom in shape achieved through molding process – Feasible boss, rib, and flange shape

- Precise, thin and rigid material property

- Premium paper texture

- Recyclable as paper*

*Depending on the regulations and guidelines of each country or region.

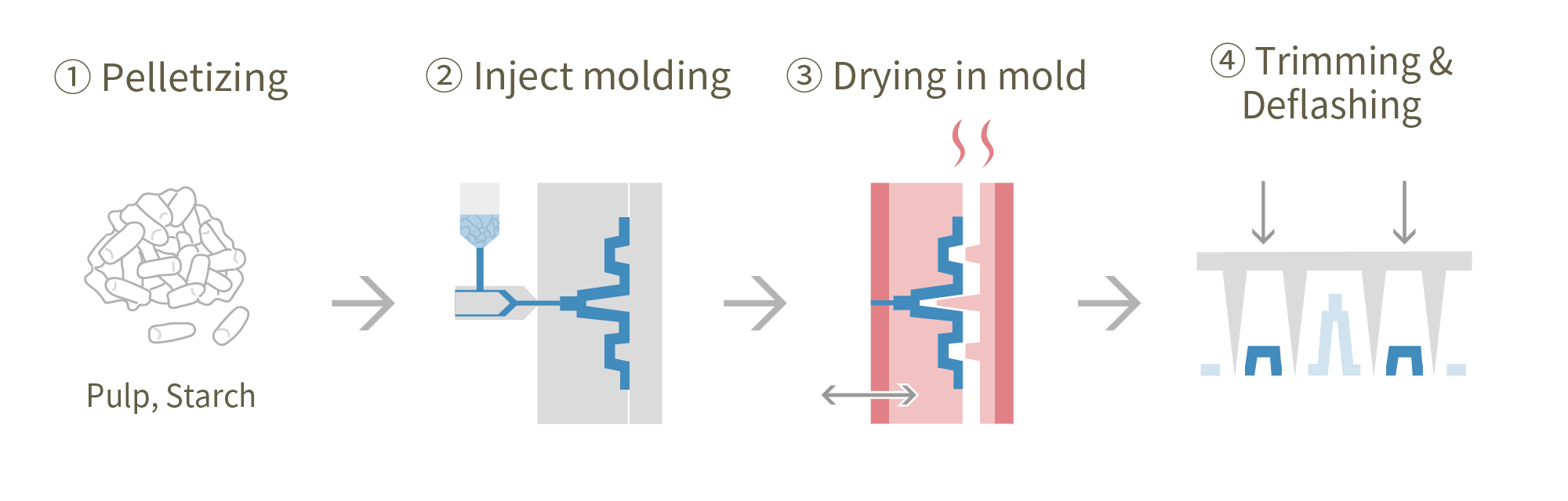

Process

- Specialized pellets made from pulp and starch as the main ingredient.

- The process involves mixing pellets with water and injecting the mixture into the mold.

- The mixture is heated to remove moisture in the mold.

- After molding, the products are trimmed to remove excess material and eliminate any burrs.

Key Features

- Thin and high rigidity

- Despite being thin with a thickness of around 1mm, it possesses strength equivalent to that of plastic, providing protection for the product against impacts during transportation.

- Premium paper texture

- The surface has a texture reminiscent of traditional Japanese paper, exhibiting minimal paper dust and a clean look.

- Extensive design freedom in shape

- Equivalent moldability to injection molded plastic, allowing for functional and versatile designs with the addition of ribs and flanges.

Applications

-

Pharmaceutical

Self injector tray -

Ampule

tray

Specification

| Max. parts size(mm) | 300 × 300 × 50 |

|---|

| Parts thickness(mm) | 0.6 〜 1.0 |

|---|

| Minimum radius(mm) | 0.5 |

|---|

| Typical production volume(annually)(pcs) | 200,000 〜 |

|---|