Pulp Series

Sustainable Molded Pulp Products –

an Alternative for Plastic to Achieve a Decarbonized Society

The Pulp Series of Nissha ecosense is a range of sustainable packaging products that offers an eco-friendly alternative to traditional plastic packaging. The series primarily comprises of biobased materials, with pulp leading the way, and reflects Nissha's commitment to environmental responsibility.

This series leverages Nissha's injection molding and material technologies to provide various forming and molding packaging components that highlight the natural texture of paper. These versatile products are well-suited for packaging needs across a broad range of industries, including pharmaceuticals, medical devices, cosmetics, CPG, electronics, stationery, and more. Our offerings include trays, outer boxes, and other packaging materials to fulfill your specific packaging needs.

-

PaperFoam

- Pulp

- Foam molding

- Foam molding of pulp and starch

- High cushioning properties

- Securely fix products or components

High cushioning for product protection

Learn more

-

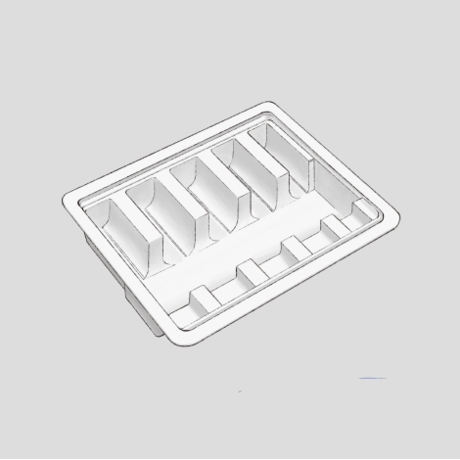

Pulp-Injection

- Pulp

- Injection molding

- Precise, thin and grid properties

- Premiun paper texure

- Complex shape by injection molding

Precise, thin and rigid properties

Learn more

-

Pulp-Molding

- Pulp

- Heat press molding

- Available in both wet and dry press process

- Various surface finishes – ranging from

smooth and luxurious to a rough texture.

Wet & Dry molded fiber technoligies

Learn more

Various applications and markets

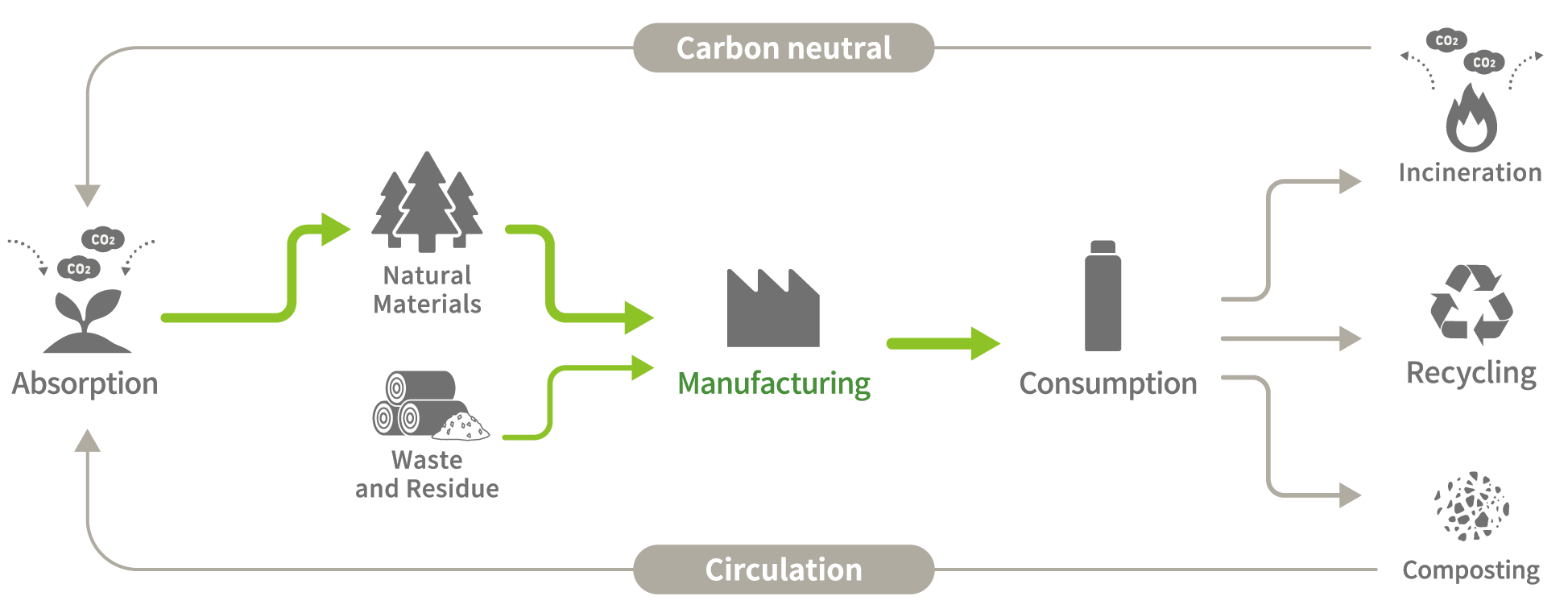

ApplicationsCircular Resources

The Pulp Series uses natural materials as its primary ingredient, making it a sustainable alternative to plastic that reduces the use of petroleum-derived materials. After use, the products can be recycled or circulated as a resource through incineration or composting.

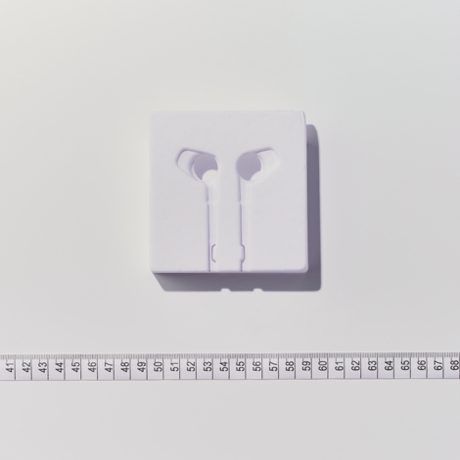

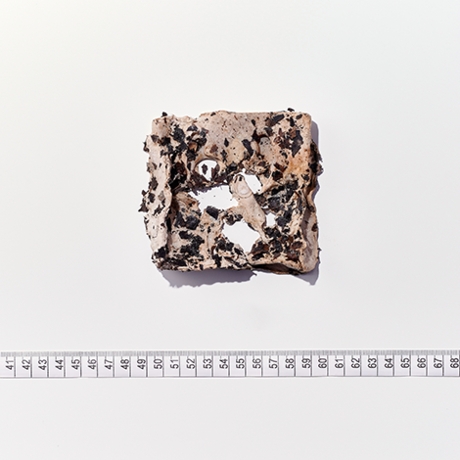

Mitigation of environmental pollution

The Pulp Series uses natural materials as its raw materials, which means it's biodegradable. By using composting facilities to break it down, we can reduce the amount of waste and prevent environmental pollution even if it ends up in nature. We conducted our own composting test and found that after six months, over 90% of molded products were decomposed and returned to the soil.

PaperFoam

1week

1week

2weeks

2weeks

1month

1month

Pulp-Injection

1month

1month

2months

2months

6months

6months

Pulp-Thermoforming

1week

1week

2weeks

2weeks

1month

1month