Pulp-Molding

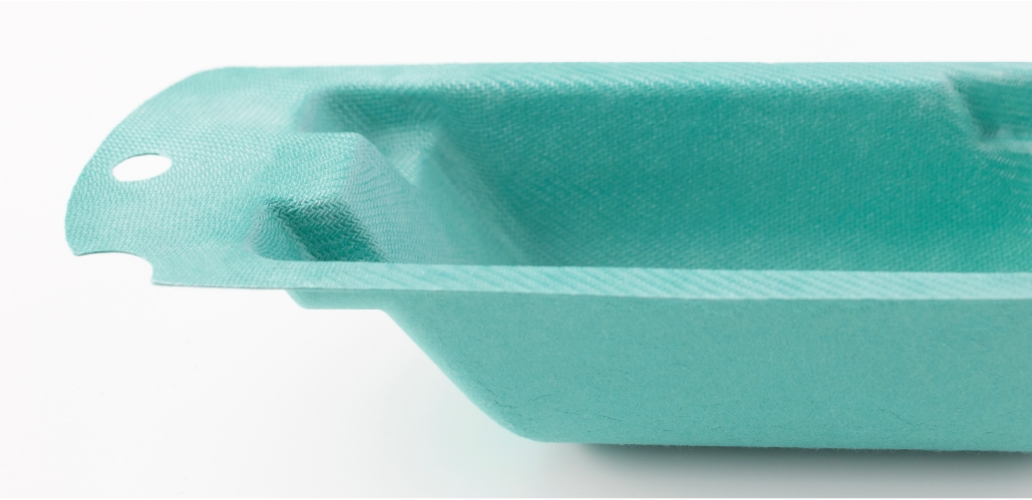

Mature fiber technology with beautiful, luxurious smooth texture

- Various surface finishes – ranging from smooth and luxurious to a rough texture reminiscent of paper.

- Precise accuracy of fit ensures a snug fit between the body and lid.

- Mold technology with minimal draft angles.

- Available in both wet and dry press process.

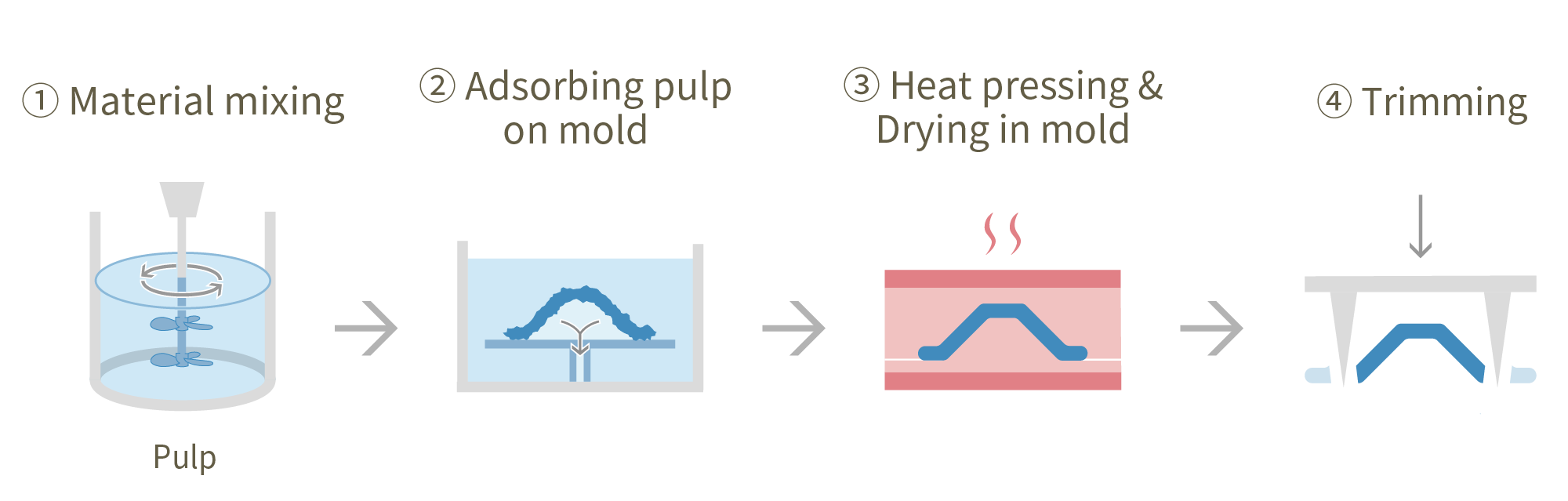

Process( wet mold )

- Pulp is mixed with water.

- Pulp is applied to a mesh-covered mold and formed.

- A press mold is utilized to clamp the material from the top and bottom, while heat and pressure is applied to press it and remove moisture.

- After molding, the products are trimmed to remove excess material.

Key Features

- Smooth and luxurious surface texture

- It features a smooth surface achieved through wet press process, providing a soft and gentle texture. It is suitable for products that require beauty and a sense of luxury.

- Thinness

- The standard wall thickness is 0.7 to 1.5 mm and can be changed freely. This construction method works with lightweight and design-oriented designs.

- Precise accuracy of fit

- It allows for the design of steep draft angles and minimal taper, enabling precise fitting of the body and lid.

- A wide variety of textures available

- Coloring and engraving can be applied. The surface of molded products can be freely textured, to blend seamlessly with a wide range of products.

Applications

-

Food

Display/package case -

Cosmetics

Mascara blister -

Cosmetics

SoftLock® Box

Specification

| Max. parts size(mm) | 960 × 800 × 80 |

|---|

| Parts thickness(mm) | 0.7 ~ 5.0* *Thick-wall parts is only available by dry process |

|---|

| Minimum radius(mm) | 1.0 ~ 2.0 |

|---|

| Typical production volume(annually)(pcs) | 200,000 〜 |

|---|