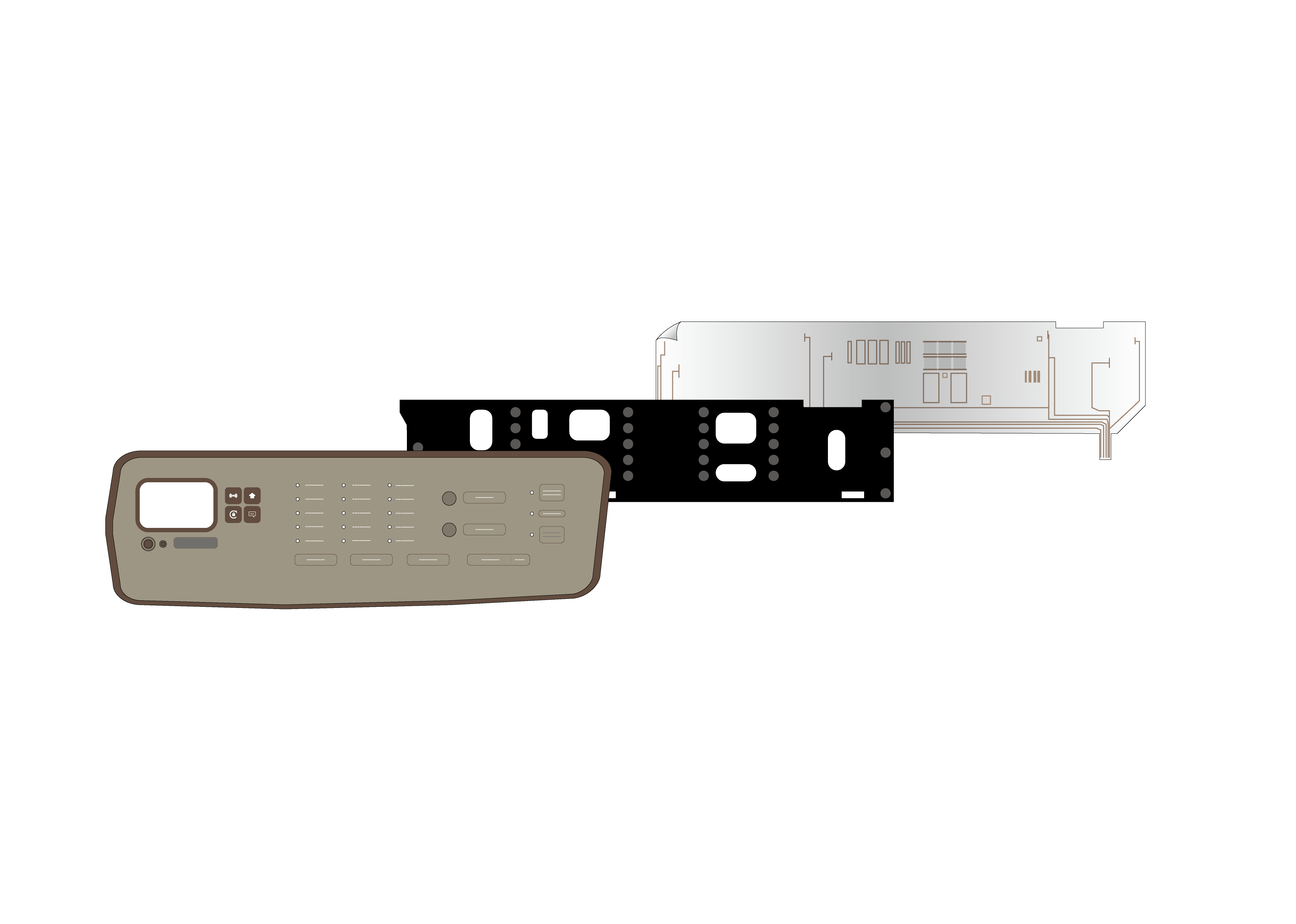

With Nissha IME, functional parts such as electrode film and FPC are integrated with resin parts by insert molding.

●Achieving Thin and Lightweight Products

With Nissha IME, functional electrodes can be integrated into parts without using adhesives such as double-sided tape. This makes it an ideal technology for creating thinner and lighter products.

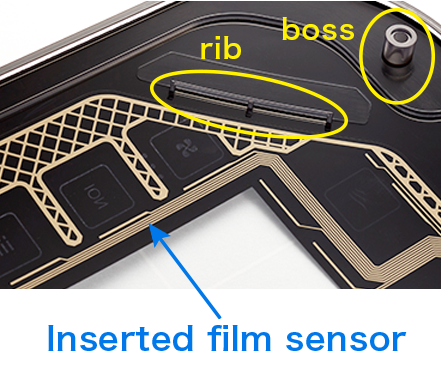

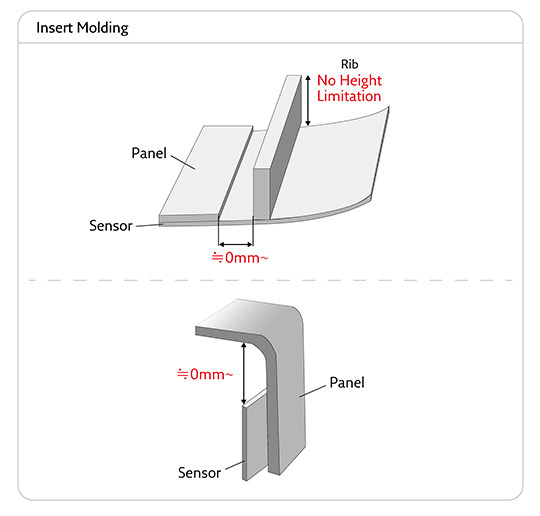

●Integration of Electrodes Even in Parts with Concave Shapes and Ribs/Bosses

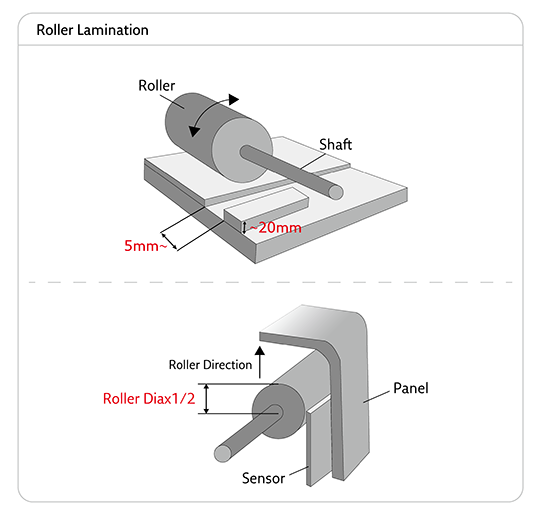

When fixing electrode films or FPCs with double-sided tape, manual bonding by hand or roller is required, which incurs significant labor costs and time. The roller bonding method cannot handle curved surfaces with ribs or bosses that interfere with the rollers or where pressure cannot be evenly applied. With Nissha IME, FPCs and electrode films are integrated through insert molding, eliminating these issues.

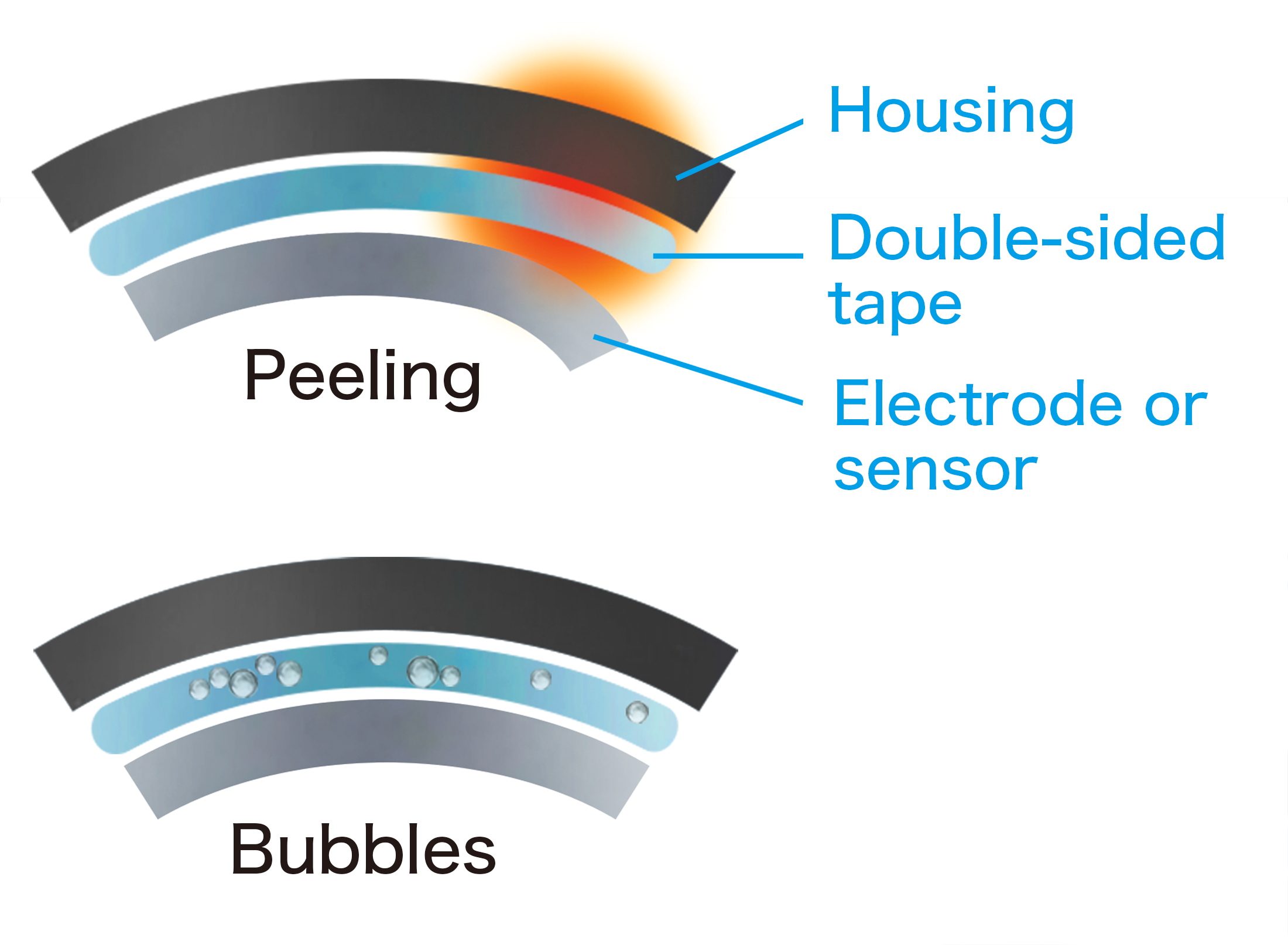

●Enhanced Reliablity

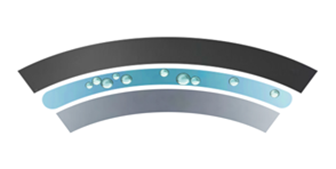

Adhesives like double-sided tape are susceptible to deterioration due to environmental factors such as vibration, UV rays, temperature, and humidity. This can lead to reduced adhesive strength, bubble formation, and discoloration (yellowing). With Nissha IME, the resin and film are bonded by the heat of molding, eliminating the need for adhesives and resolving these reliability issues. Additionally, it creates a seamless shape, providing excellent waterproof and dustproof properties.

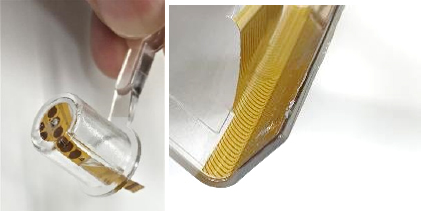

●Support for Minute Spaces That Are Difficult to Bond

As electrical appliances become smaller and thinner, there is an increasing need to place electrodes and sensors in very small spaces. The strength of adhesives like double-sided tape decreases as the bonding area becomes smaller. Bonding in small spaces requires laborious manual work, which is costly and time-consuming. With Nissha IME, electrodes and sensors can be securely fixed by insert molding even in such small spaces.

This section describes the layer structure when electrodes are inserted using Nissha IME. For the electrical connection method between the electrode and the board, you can select either an FPC connector or a spring terminal/pin mounted on the board.

| Roller Lamination | IME | |

|---|---|---|

| curved surface | Up to 2D geometry | 3D surface is feasible (MAX:R500xR700) |

| Backside Feature in Specific Area | Restricted (Due to the range of the lamination roller motion) | Free from roller dia. restriction |

Adhesives can experience various issues due to aging, environmental influences such as high temperature, high humidity, and vibrations. Adhesive-Related Quality Issues

Bubbles can form during the lamination process or under certain environmental conditions, potentially altering sensor properties and causing visual defects on displays.

Delamination can occur due to aging or vibration, which may change sensor properties and cause visual defects on displays.

Yellowing can result from aging or specific environmental conditions, leading to visual defects on displays.

Adhesives can absorb moisture, which may change dielectric constants and alter sensor properties.

High-temperature environments can cause delamination, leading to changes in sensor properties.

Low-temperature conditions can alter adhesive dielectric constants, affecting sensor properties.

Nissha has various testing facilities.

Here are examples of reliability test specifications applied to Nissha IME for home appliance applications. We can perform reliability tests in our in-house testing environment, provide feedback to the design team, and propose the most appropriate design to customers.

| High temperature storage | Low temperature storage | High temperature high humidity storage | Heat cycle | UV resistance |

|---|---|---|---|---|

| +70°C 240Hrs |

-40°C 240Hrs |

+60°C/93%Rh 240Hrs |

-25°C/1Hrs ⇔+60°C/1Hrs 10cyc. |

Xenon weathermeter |

Please feel free to contact us.

CLICK