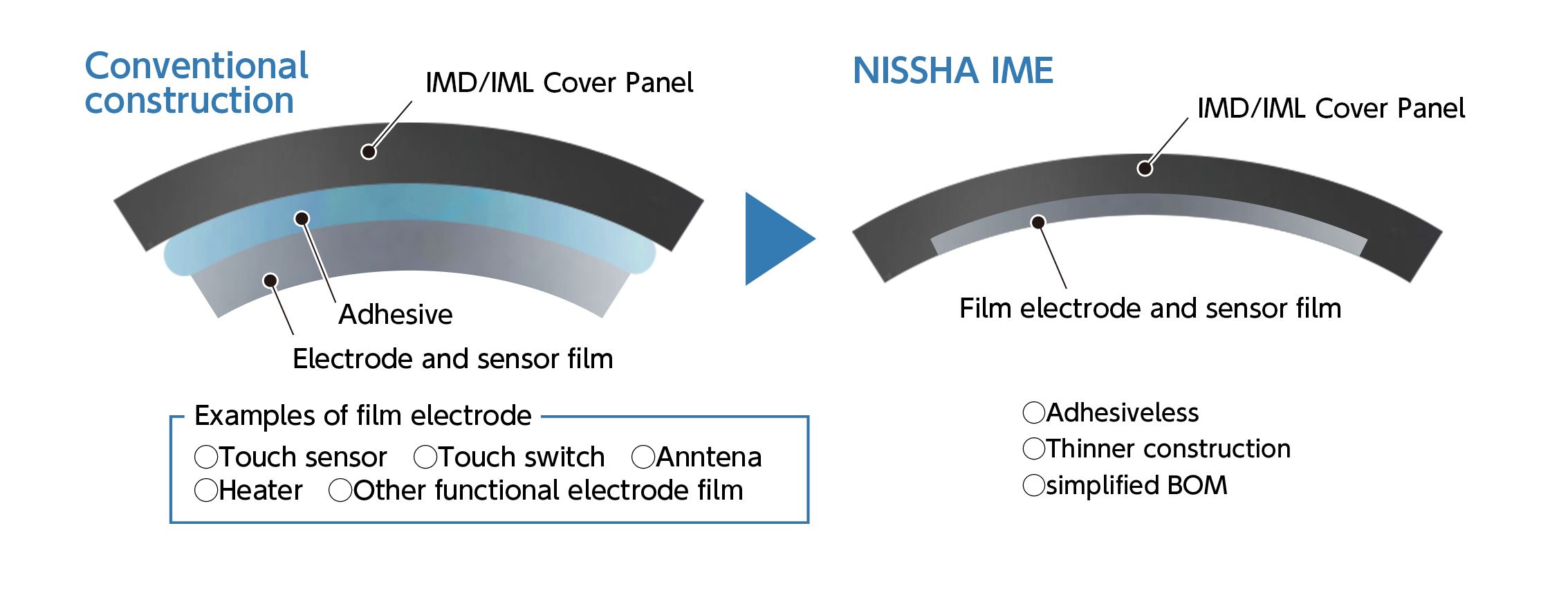

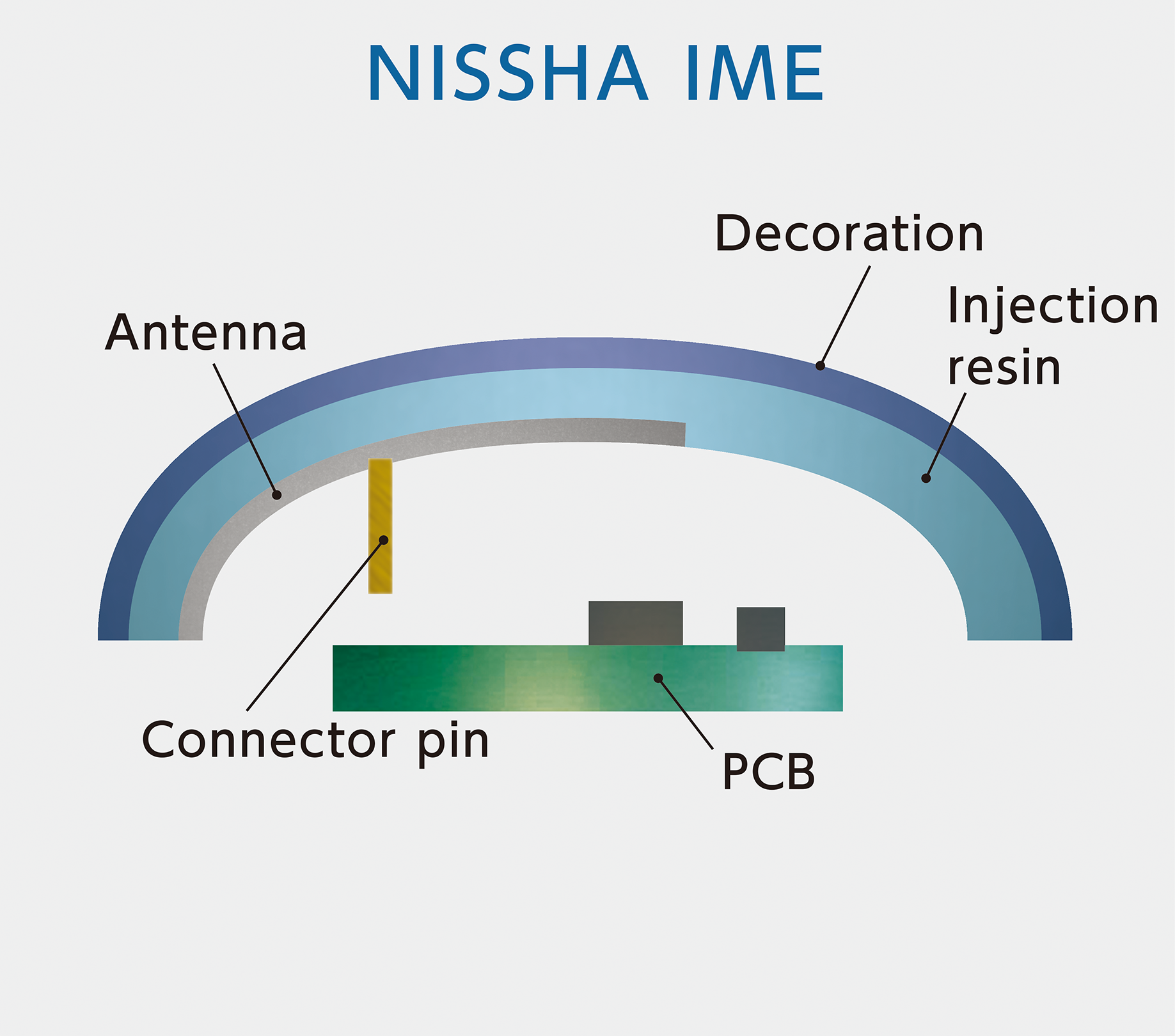

NISSHA IME is a technology of MID (Molded Interconnect Device). Film electrode is integrated on molded parts by insert molding, even on 3D or curvature, where conventional assembly method or plating technology such as LDS cannot. You can save some process steps. NISSHA can propose the most appropriate construction to customers including stack-up of film electrode and its output method.

NISSHA IME can integrate film electrode into complex shapes with curved surface and structures.

Not using adhesive layer, it works with thinner and complex construction, reduces components numbers and process steps and improve the quality.

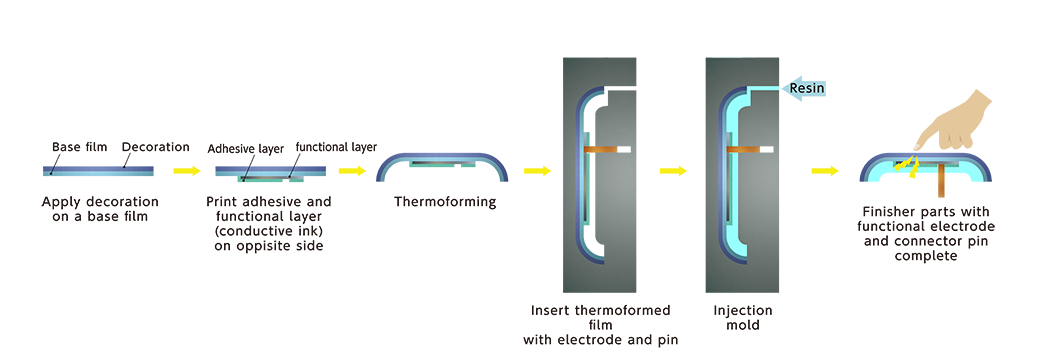

①Electrode placed on surface side of injection molded parts(Connection to electrode: Metallic pin)

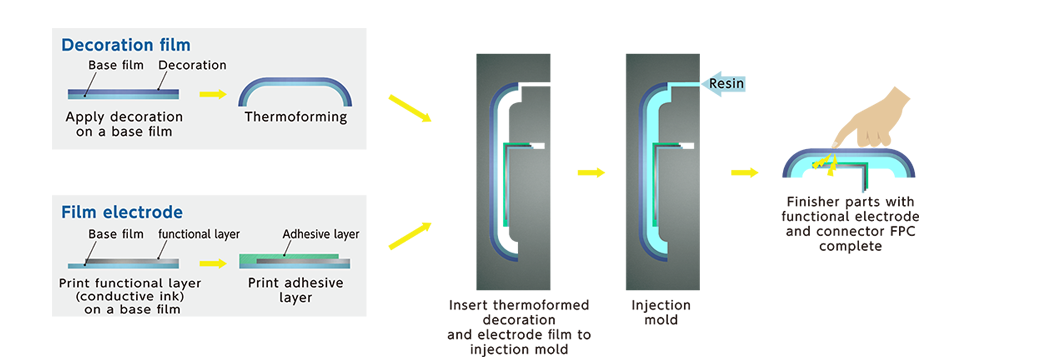

②Electrode placed on backside of injection molded parts(Connection to electrode : FPC)

NISSHA IME offers choices of film electrode position and circuit output way.

We offer most suitable proposal for your design and usage.

| PINS | FPC connectors |

PINS

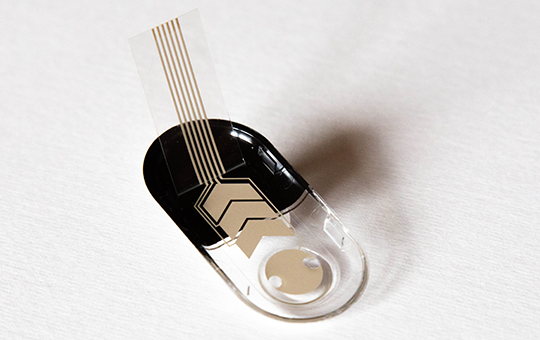

1 Electrode patterned on the back side of decoration film is put over the molded part.

Inserted pins connected to electrode work as circuit output.

FPC connectors

2 Electrode patterned on the back side of decoration film is put over the molded part.

Extended circuit from film electrode work as circuit output.

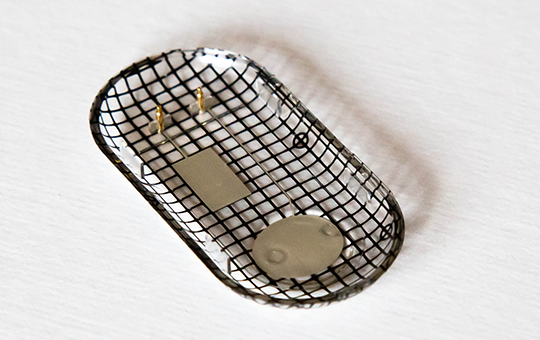

FPC connectors

2 Electrode patterned on the back side of decoration film is put behind the molded part.

Extended circuit from film electrode work as circuit output.

①An electrode placed right beneath surface decoration film

②An electrode placed on backside of panel

③An electrode placed right beneath surface decoration film and An electrode placed on backside of panel

For more detail, actual samples are prepared, by multiple construction variations.

Please feel free to contact us for your interest.

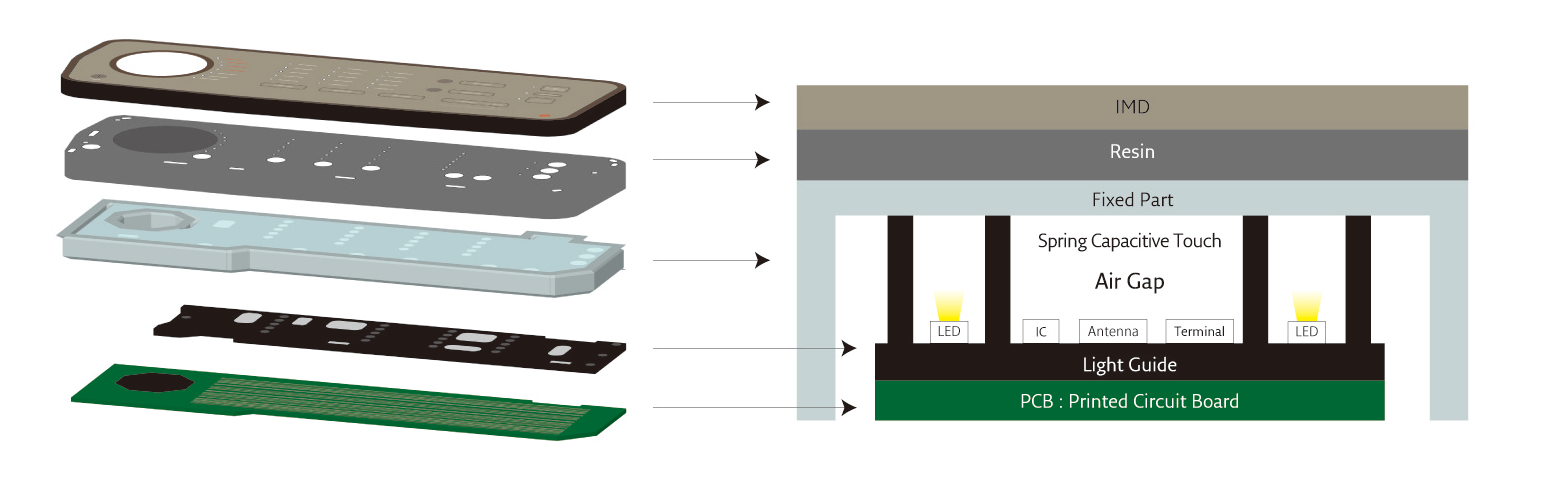

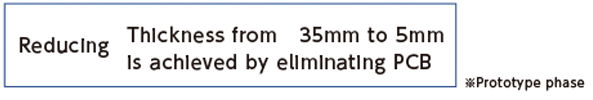

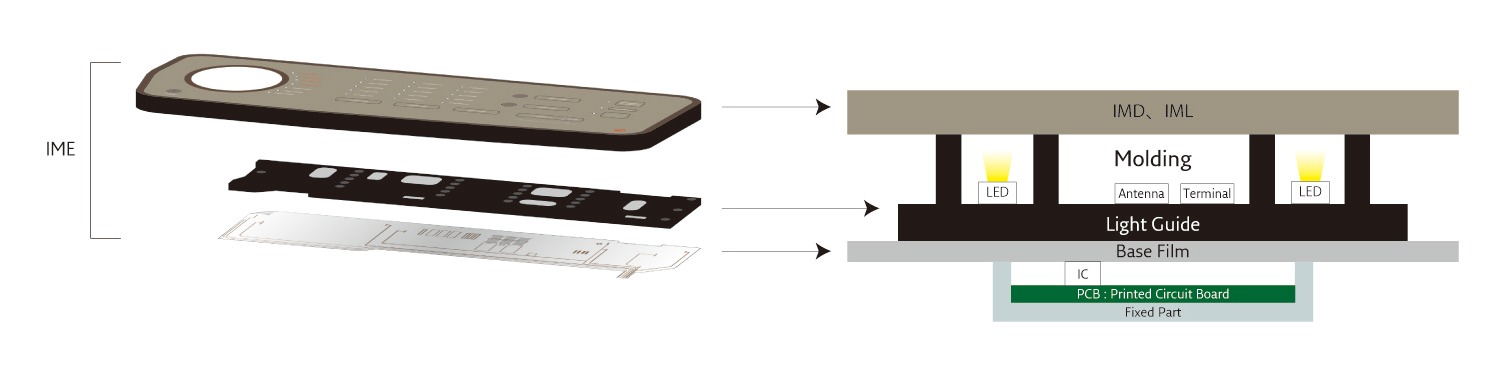

By Integration of film electrode and functional parts such as LED to cover parts, NISSHA IME do not need adhesive layer and cuircuit board for sensor. It enables simpler assembly and reduces component and process numbers, and improvement of reliability.

NISSHA IME can integrate LEDs on film electrodes by insert molding. And contribute to reduce number of components and achieve smaller PCB or thinner products

Conventional Construction

Nissha IME

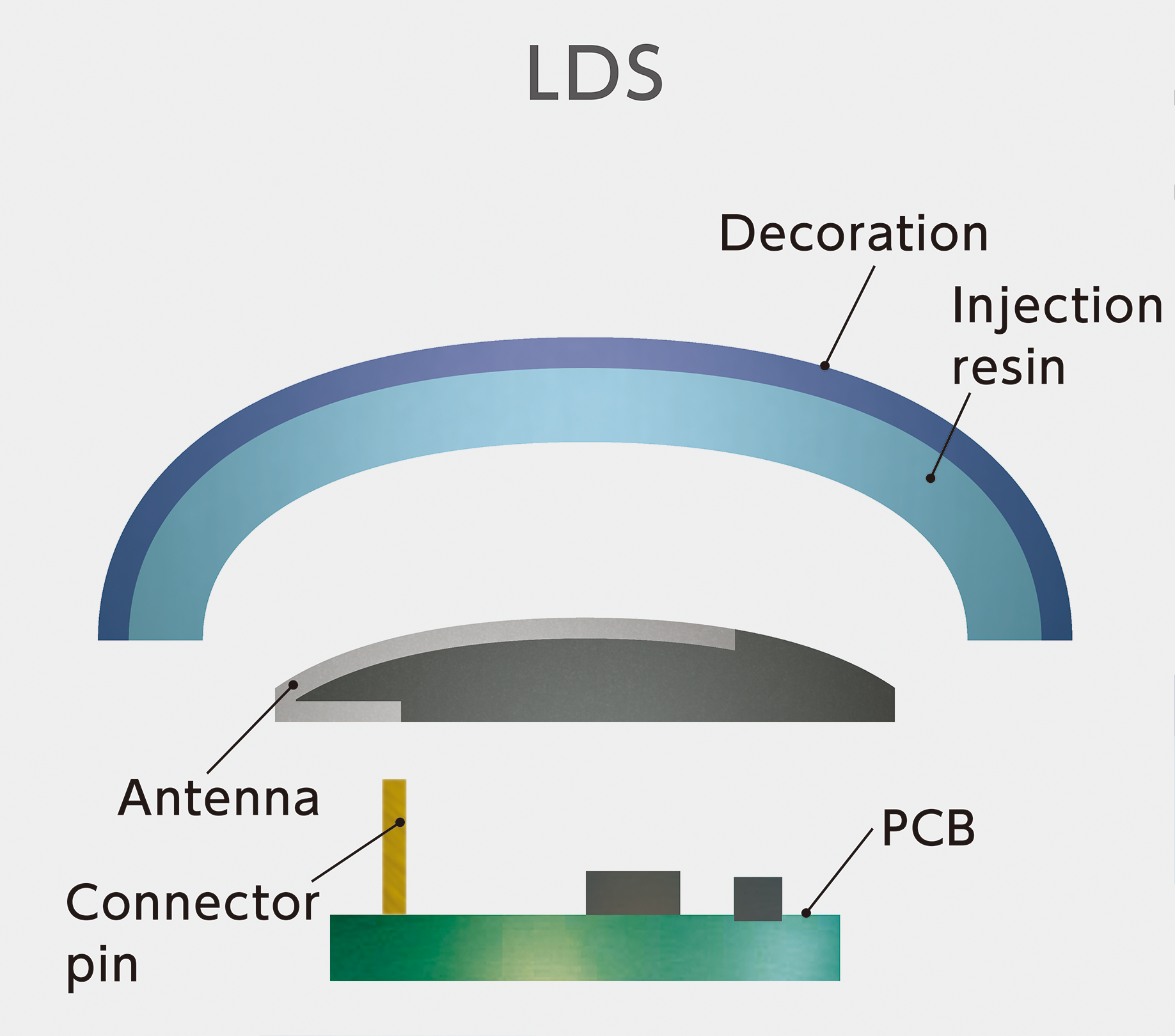

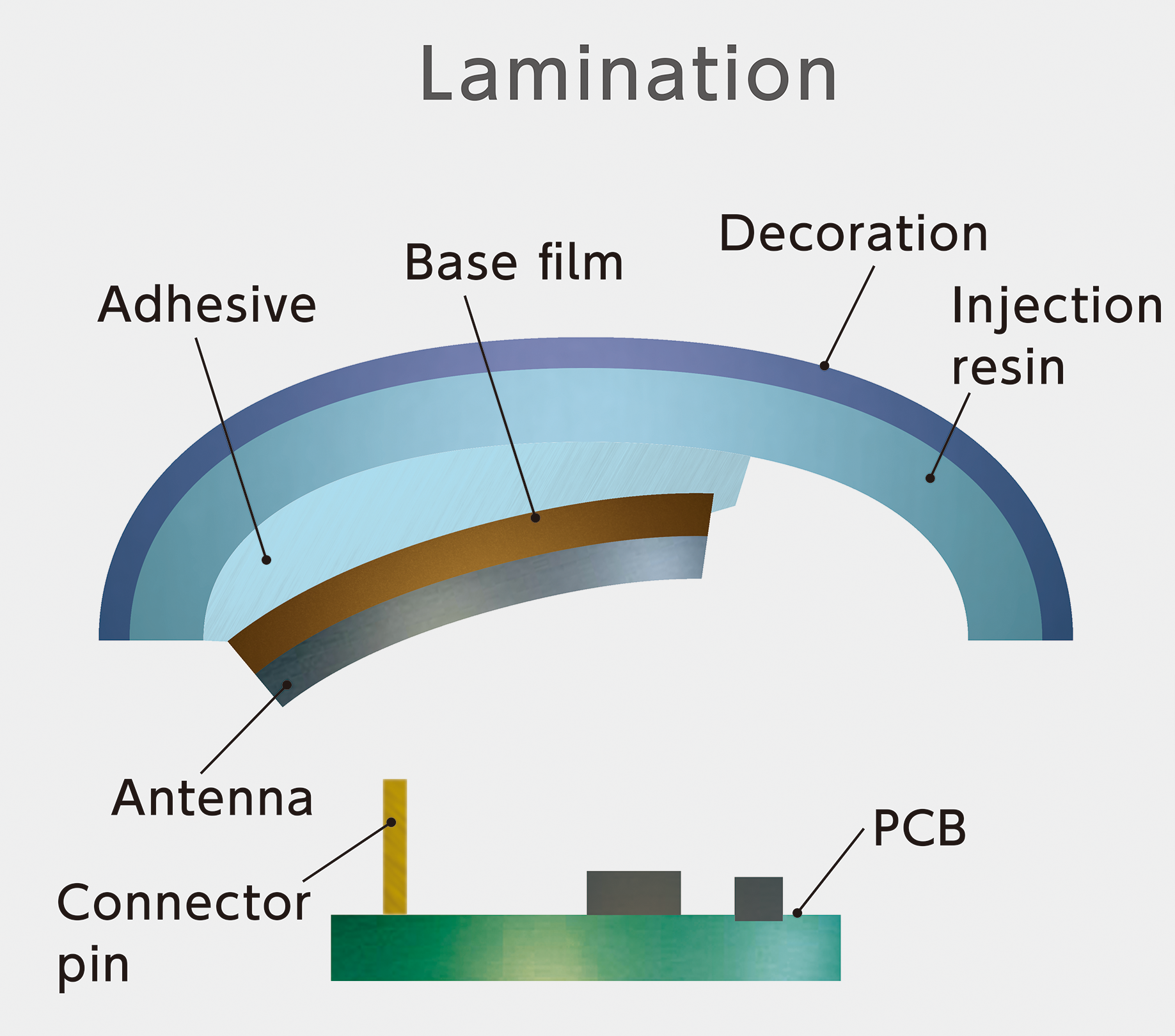

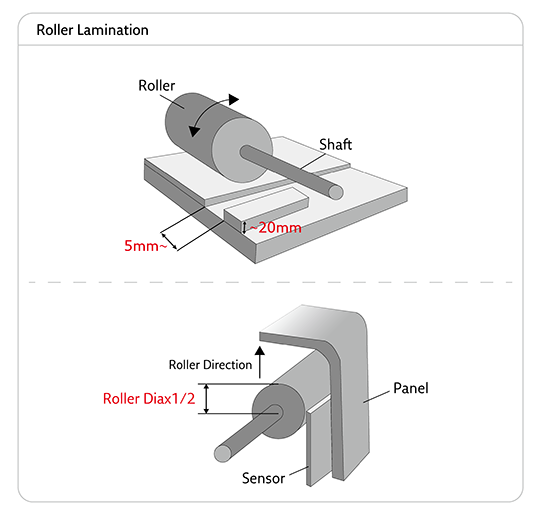

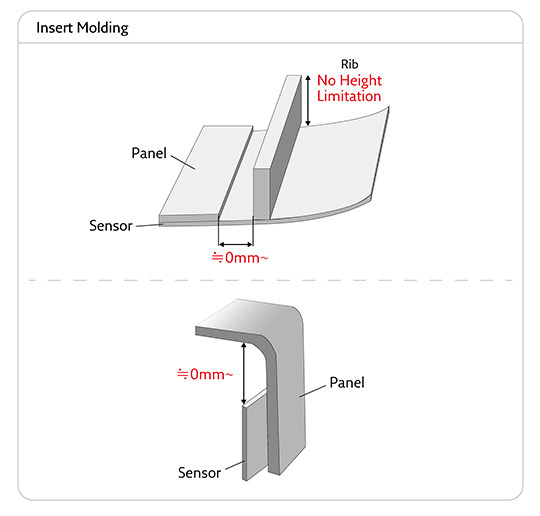

In order to laminate thin film shaped sensors or electrodes to plastic molded parts, it is necessary to apply roller lamination method by elastic plastic based or double sided tape type of adhevsives.

It is necessary to apply adequate pressure by roller to laminate, therefore roller lamination process is unable to apply to cases such as to laminate near obstacles like libs, or concave surface a uniform pressure is unable to be applied.

On the other hand, as NISSHA IMD integrates film sensors or electrodes by insert molding process, it is possible to apply to such a complex geometry.

| Roller Lamination | IME | |

|---|---|---|

| curved surface | Up to 2D geometry | 3D surface is feasible (MAX:R500xR700) |

| No backside feature in specific area | Restricted (Due to a range lamination roller motion) |

Free from roller dia. restriction |

NISSHA have CMF designers internally. With full knowledge of Nissha’s technology, production cost and productivity, they can offer the design most appropriate to customer from concept stage.

Please feel free to contact us.

CLICK