IMD and IML can add to your products various designs in terms of colors, patterns, and surface finishes.

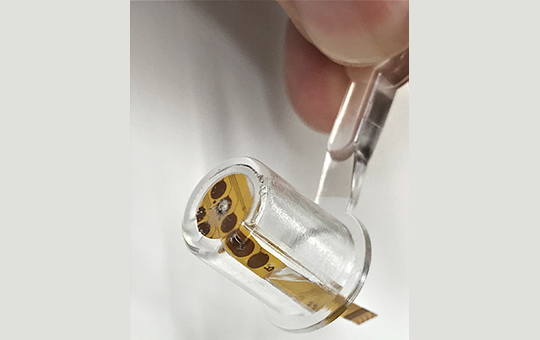

Moreover, electric functions, such as touch sensor, button, and LED, can be integrated into your product surface with Nissha IME.

This integration of aesthetic design and electrical function enables thinner and lighter product design as well as efficiencies in assembly process or supply chain.

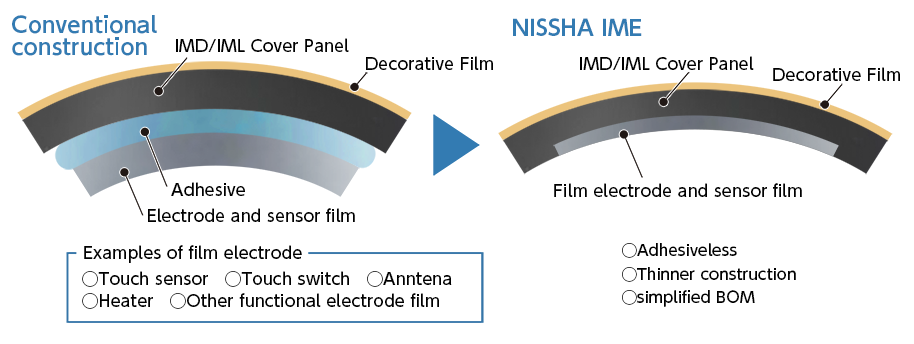

Conventional way of adding electric functions such as touch sensor, button, and LED to a product enclosure panel is to separately attach functional components (e.g. electrode film, FPC, etc.) behind the housing panel with adhesive tape or dedicated assembly process.

With Nissha IME, this integration becomes more seamless both in terms of product design and manufacturing process.

Typically, dedicated process is required to add functions such as touch sensors and buttons onto an inejction molded plastic part; electrode film or FPC needs to be attached by adhesive materials post molding.

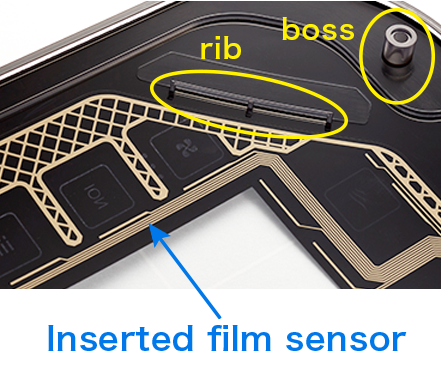

However, this type of conventional process is not feasible or becomes very cumbersome when part surface is curved or has ribs and bosses.

Nissha IME addresses such challenges by streamlining the manufacturing process to integrate electrode film or FPC with molded plastic part.

Consumer electronics industry relentlessly has been striving to achieve reduction in overall product thickness and weight, and the importance of this requirement only continues to increase as “sustainability” takes a center stage globally.

Nissha IME tackles this challenge by integrating functional electrodes into molded parts without the use of adhesive tapes or dedicated process, thereby contributing to thinner and lighter product design.

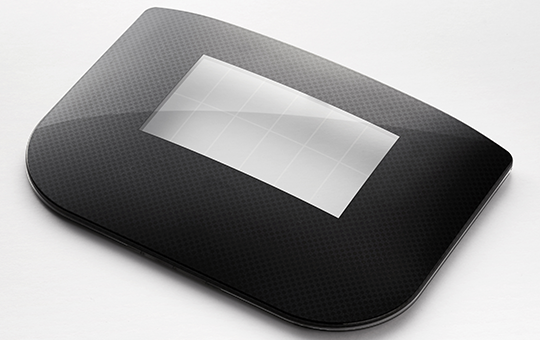

Seamless and smooth product surface is possible with the use of Nissha IME solution as it integrates touch sensors and buttons behind aesthetically pleasing UI panels.

While achieving sleek appearance and feel, it also provides enhanced reliability thanks to the improved waterproof and dust-proof performances.

“Hidden-till-lit” effect, also known as “dead front” effect, is a design feature where certain icons and texts are made to be invisible to an user when not activated and only show up when activated, typically with a touch input by the user, blending your product into surrounding environment.

Nissha IME can help you accomplish this type of effect for your product as we have ideas, know-how, and experience in both sides of aesthetic design and electrical function as well as the integration of those.

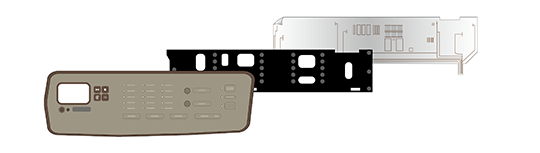

Nissha IME can be used for small to large size applications; maximum size it can accommodate is approximately 800 mm.

Wide variety of products can benefit from Nissha IME because of our flexibility to accommodate different sizes.

Your choice of material should not be limited to plastic only. Other materials such as real wood veneer, fabric, or artificial leather deliver natural warmth and intrinsic feel indifferent ways.

By utlizing Nissha IME and seamlessly integrating electrical function to authentic materials, we can be delivering products that exude natural feel, blend into ambient settings, and coexist with users in non-intrusive and sustainable manner.

Nissha CMF designers can propose various design ideas for you.

Seamless and smooth product surface is possible with the use of Nissha IME solution as it integrates touch sensors and buttons behind aesthetically pleasing UI panels.

While achieving sleek appearance and feel, it also provides enhanced reliability thanks to the improved waterproof and dust-proof performances.

Please feel free to contact us.

CLICK