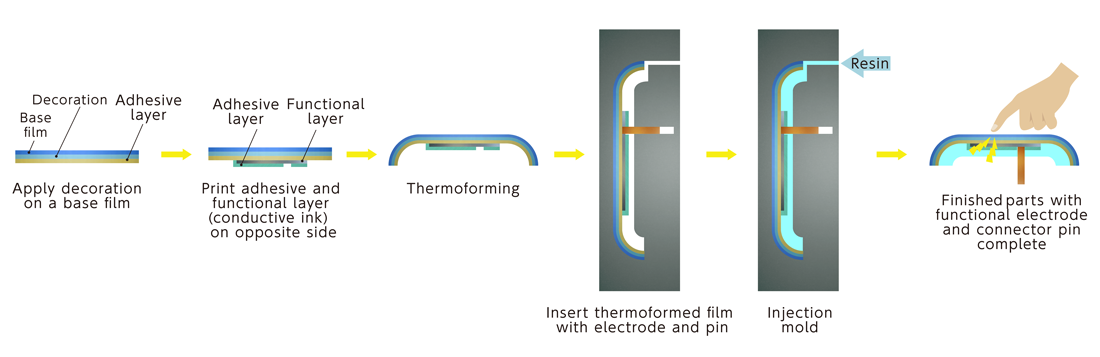

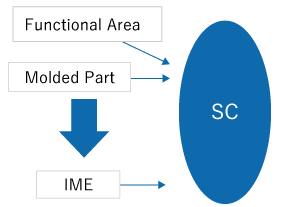

①Electrode placed on surface side of injection molded parts(Connection to electrode: Metallic pin)

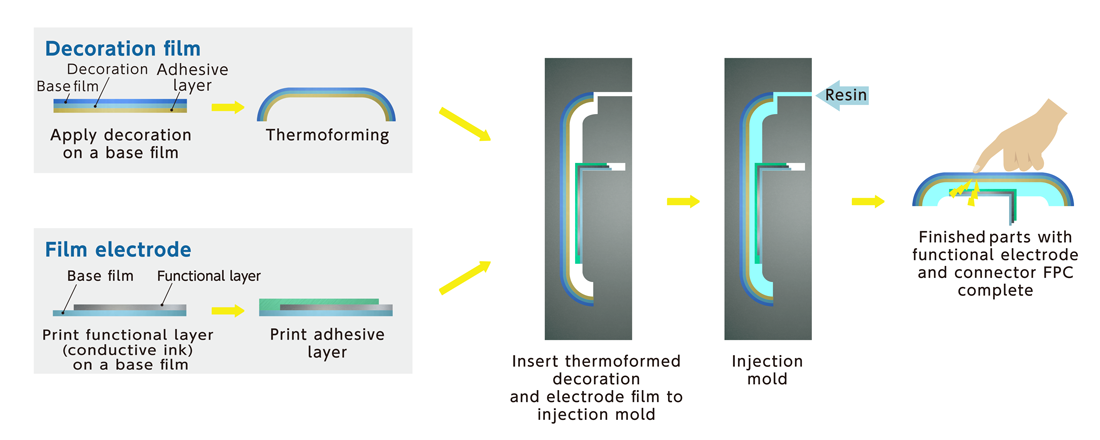

②Electrode placed on backside of injection molded parts(Connection to electrode : FPC)

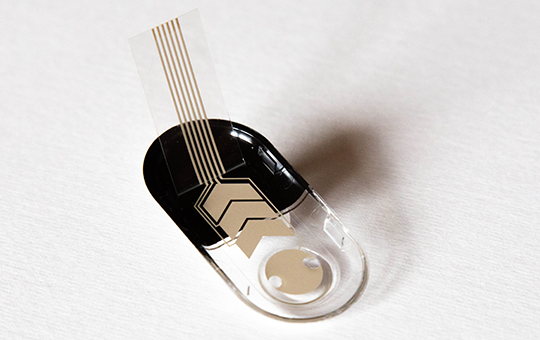

For more detail, actual samples are prepared, by multiple construction variations.

Please feel free to contact us for your interest.

In order to form electrodes and circuits on curved and uneven molded resin, the LDS method,

which is one of the MID technologies, and the method of attaching the electrode film and FPC using an adhesive such as double-sided tape have been used.

However, both methods have some weaknesses.

For example, there are problems such as restrictions on the shapes and electrode patterns that can be handled,

and increased labor and cost.

NISSHA IME solves these problems and is a technology that can be applied to a wider range of products.

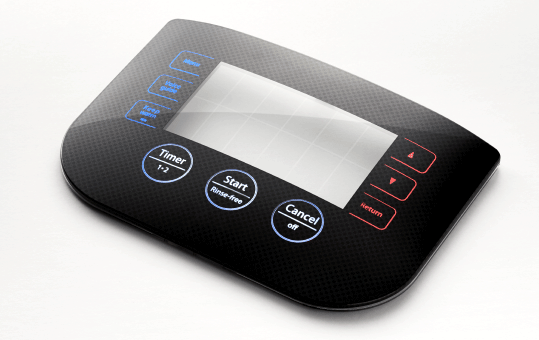

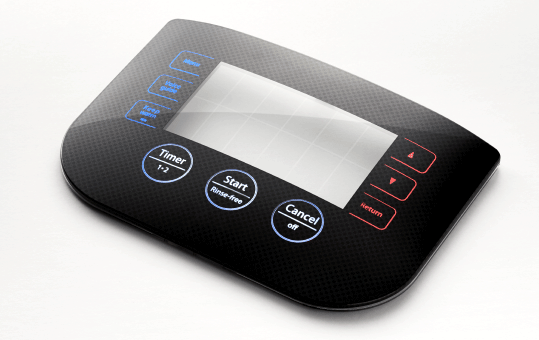

NISSHA IME can integrate not only functional electrodes.

By insert-molding a wide variety of design films at the same time, it is possible to achieve a highly designed appearance.

In addition, since transparent resin can be used,

it is possible to realize a Hidden-lit design that makes display part stand out beautifully.

Additionally, it is possible to add functions that match the customer’s product application,

such as adding a tactile sensation and giving the surface an antibacterial function.

You can achieve multiple colors, patterns, and different material look, which painting hardly achieve.

Nissha IMD have strengths in backlit expression

using transparent resin.

With LED, it is also possible to realize a Hidden-lit design.

Nissha IMD can provide you design with touch feelings,

like “Soft”, “Smooth” and “Grippy” feels.

A functional layer with anti-bacterial property can be added to the product surface.

With Nissha’s reliable anti-bacterial performance, it acheaves clean and safe user interface.

"Module" IME part can save assembly steps at customer.

You can save the trouble of procuring parts that were arranged separately.

IME is more environmental friendly process than painting, using less volatile solvent.

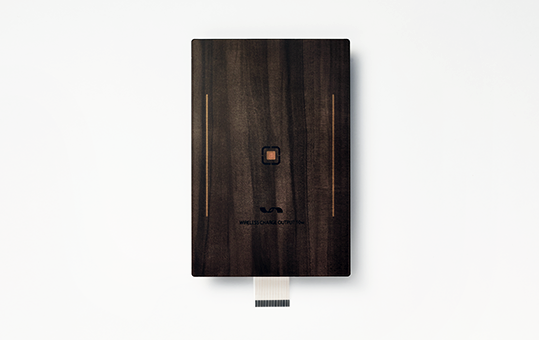

NISSHA IME can realize various electrical functions by integrating resin parts and a board on which electrical parts are mounted.

NISSHA IME is ideal for wearable devices that require miniaturization and weight reduction.

For example, communication quality can be improved by forming sensors on the product surface.

NISSHA IME is ideal for in-vehicle devices that require strict reliability characteristics such as high temperature, low temperature, and vibration.In sddition, it can be applied even to large size parts.

NISSHA IME’s adhesive-less structure solves the problem of leaching and peeling of adhesive components. In addition, the seamless structure can improve waterproof, dustproof, and sweat resistance.

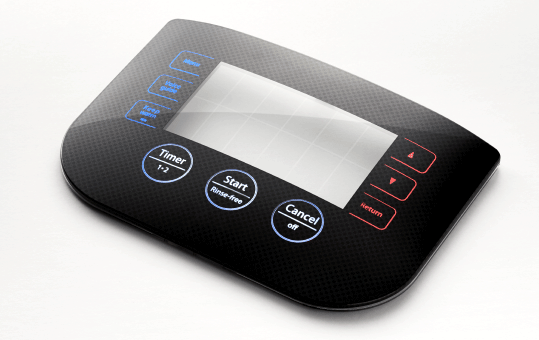

By combining NISSHA IME and various design expressions, we realize high functionality and stylish design that blends into the interior.

NISSHA IME is ideal for mobile devices that require smaller size and lighter weight as well as wearable devices. Sensors, etc. can be placed in a limited space.

NISSHA IME also supports large size.For example, the seamless design that integrates the operation panel with sensors and switches improves waterproof performance.

NISSHA have global production sites and can supply products quickly.

Please feel free to contact us.

CLICK