NISSHA has accumulated various process know-how for punching film elements patterned by roll-to-roll method into individual pieces and processing them into modules that can be mounted on final products.

We will deliver products in a form that meets the needs of our customers. We are good at finishing with high dimensional accuracy.

Laminates multiple film elements and functional films. Various types of film materials can be attached.

Die cutting and laser cutting support punching into individual pieces.

* Laser cutting is a technology under development.

Processing with punching position accuracy of ± 150um is possible.

We have a proven track record in punching difficult-to-handle film substrates such as COP.

In addition, half cut is also supported.

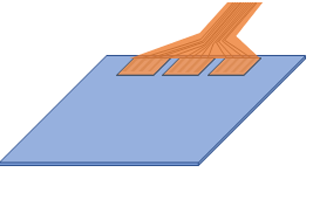

One side

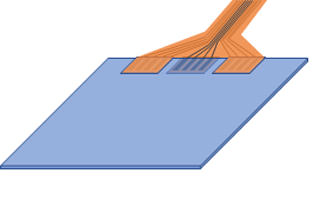

Both sides

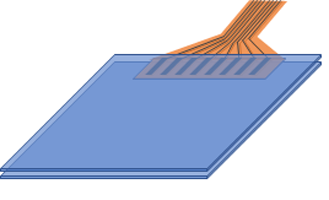

Upper and lower film sandwich

This is the process of bonding FPC on film element. Since FPC bonding is performed at the same time as electrical inspection, a high yield is achieved.

Single-sided, double-sided, sandwiching between films, and special FPC bonding are also available.

It can be bonded to polarizing plates, shielding materials, LCD modules, etc., and also to the housing on which film elements are mounted.

In addition to bonding with flat plates such as glass and plastic sheet materials, it also supports bonding with special parts such as curved cover parts and large plastic molded products.

Delivery of film element alone

Delivery with film element with FPC

Delivered as a bonded product with other functional parts

Cover module

LCD module

We support your consideration through various communications.

– We will contact you quickly by e-mail, telephone, Skype.

– We will prepare samples and data according to the contents and visit.

* Please note that it may not be possible to respond depending on conditions such as remote locations.

The Nissha Gallery at the Kyoto headquarters offers a wide range of products.

Please feel free to apply for a tour.

* We do not open to the public.

Please feel free to contact us for any questions or consultations on film devices, including consultation on development, trial production, mass production consignment, etc.

CLICK