We can customize gauges tailored for your unique design.

Flexible design

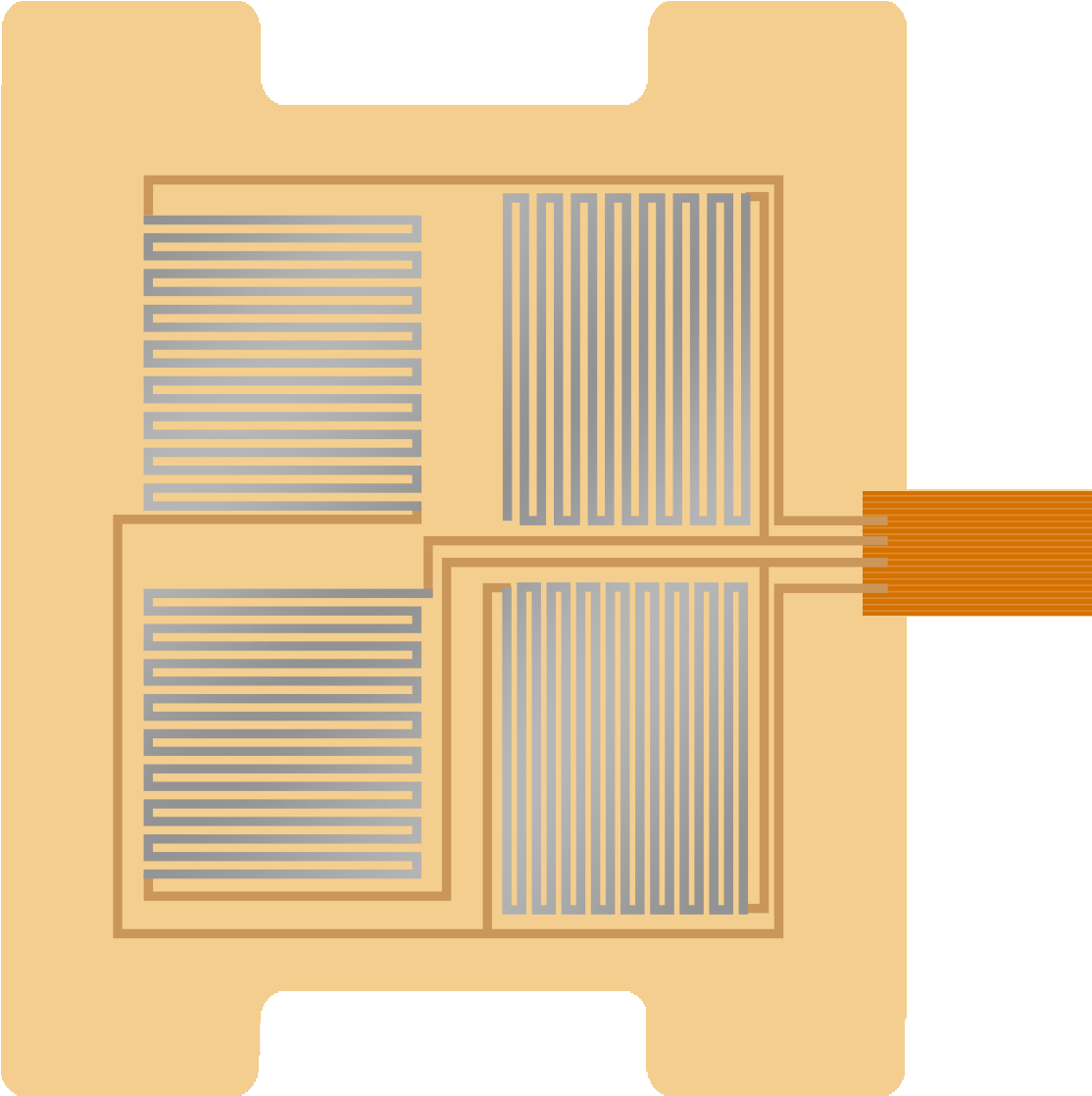

Special pattern geometries, trim dimensions, etc.

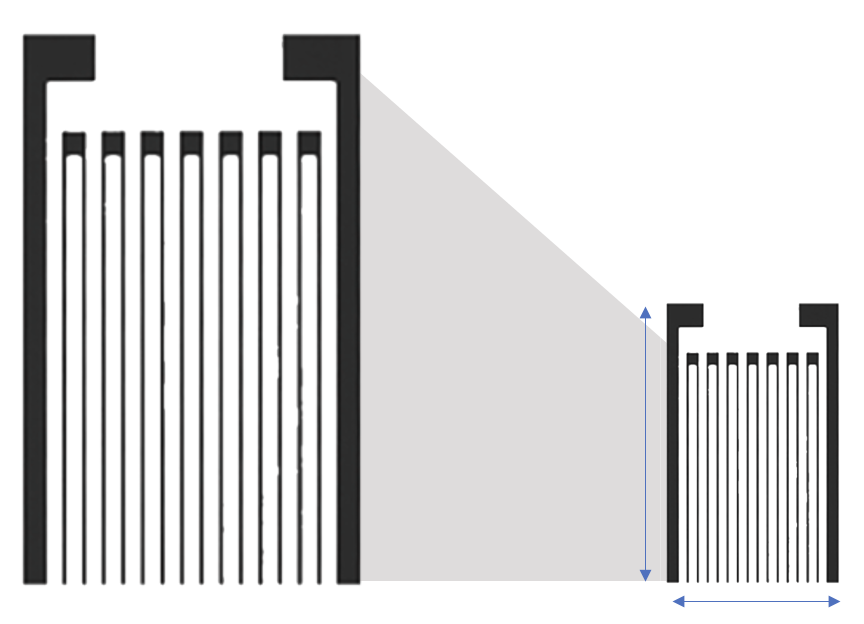

Gauge miniaturization

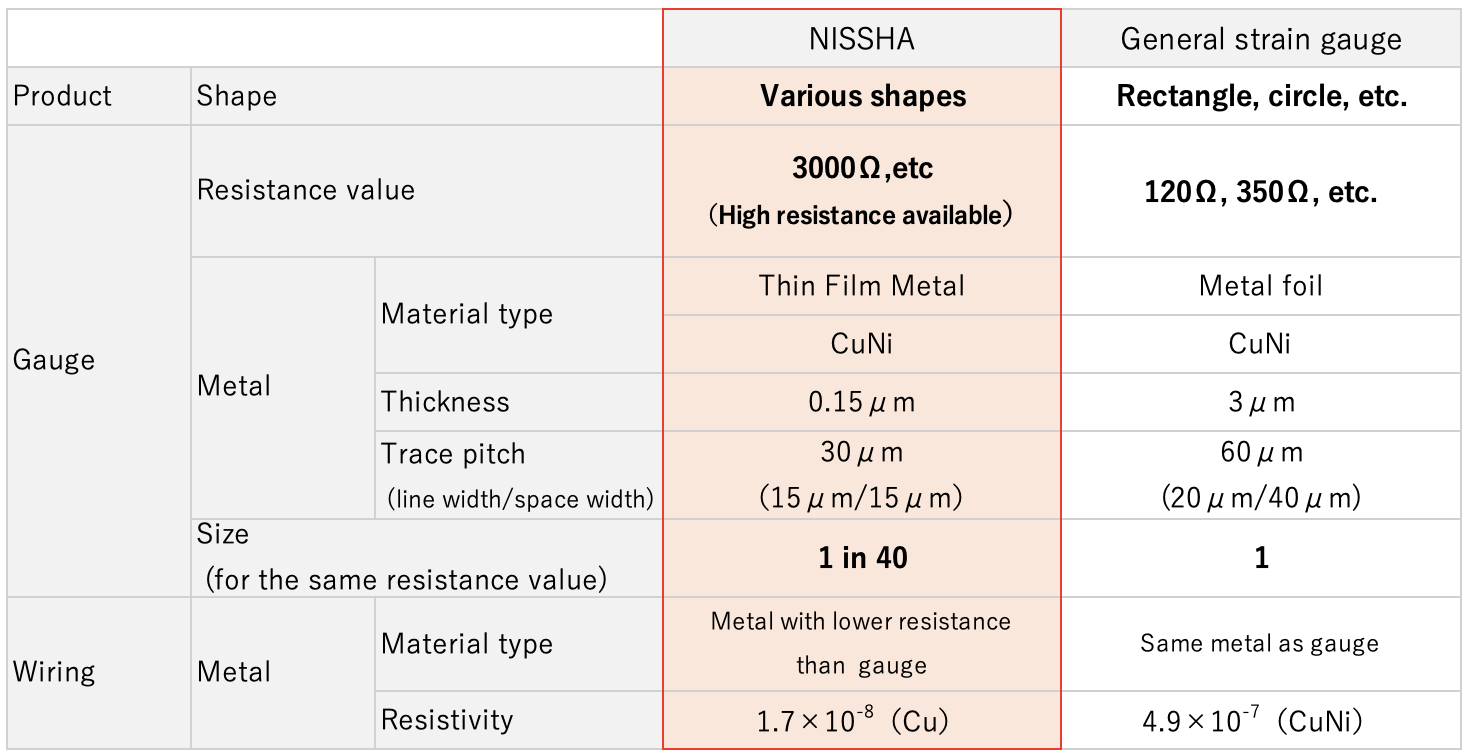

By replacing a metal foil with a sputtered thin film for the gauge, our fine etching process can be applied for miniaturization.

For example, a full bridge circuit can be fabricated on a small piece of a substrate.

A copper thin film on the grid material (ex. CuNi) drastically reduces the electrical resistance of routing traces.

Comparison with general strain gauges† †CuNi foil

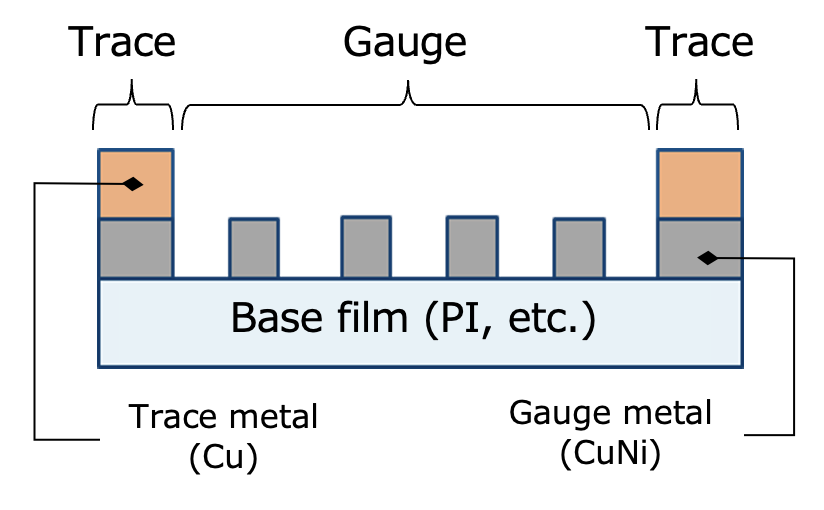

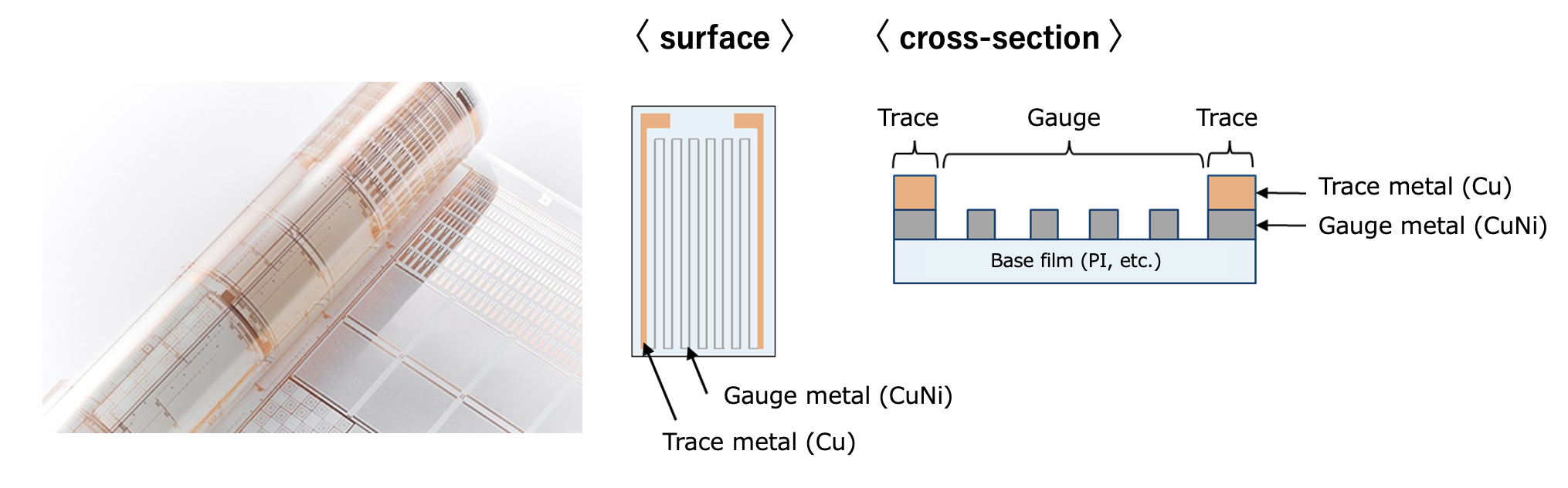

High precision patterning of multi-layered thin film metals.

Multi-layered thin film metals are selectively patterned by our photo-etching process.

CuNi for the gauge grid and Cu for the routing traces.

Customization can also be provided, for example, FPC bonding instead of leading wire soldering and adding temperature sensing elements on the same substrate.

Customized strain gauges can be applied to a wide range of applications and fields including machining tools, industrial robots and medical healthcare for the following measurements;

・Load

・Pressure

・Vibration

・Acceleration

・Torque

・Machine Tools

・Industrial Robots

・Medical&Healthcare

Please feel free to contact us for any questions or concerns.

CLICK