We support the production of sensor modules that customers want to realize.

Sensor modules such as strain gauges and temperature sensors are generally sold as standard products.

However, there are many cases where the specifications of such off-the-shelf products limit the design in developing new products.

NISSHA is capable of patterning Cu alloy thin films used in such sensors. We support customers’ product development with wiring narrowing technology that can be realized only by processing thin films with a thickness of 1 μm or less.

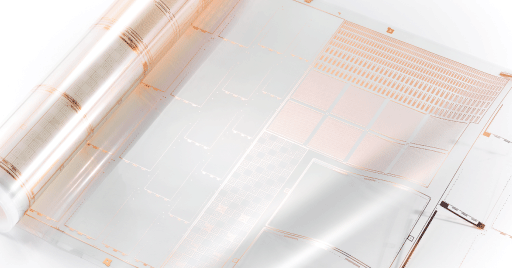

The Cu alloy thin film sputtered on PET film is patterned by photo-etching.

Compared with general alloy foil, the metal thickness is about 1/20, and a higher resistance pattern can be formed.

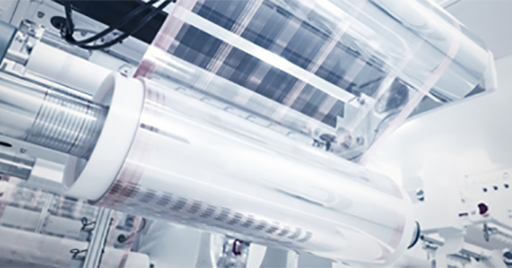

We mass-produce patterns on a roll film with a film width of 500mm.

Therefore, you can manufacture not only individual sensor parts, but you can also design more freely by laying out multiple sensors on one sheet.

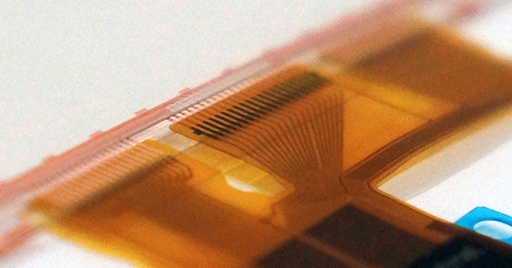

We will undertake not only patterning but also various processes to complete the sensor module.

-Insulation coating of patterning layer

-Printing of Ag circuit

-FPC bonding

-Bonding with housing parts

Copper-nickel alloys containing approximately 50% Ni are called constantan.

Constantan has a higher resistivity than copper and has a smaller temperature dependence of resistance, so it is used for products that require precise resistance characteristics such as strain gauges. Constantan is also known as a thermocouple electrode material combined with a copper electrode.

Resistivity of wiring alloy

| Resistivity(Ωm) | |

|---|---|

| Copper(Cu) | 1.7*10-8 |

| Constantan(Cu:Ni=55:45) | 4.9*10-7 |

| Nichrome(Ni:Cr:Mn=77.5:20:2.5) | 1.5*10-6 |

A CuNi thin metal with a thickness of 0.1 to 0.2 μm is a material with higher resistance than a general copper alloy foil with a thickness of about 3 μm.

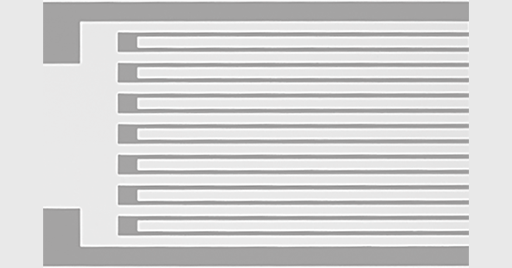

For example, the resistance of a 0.15-μm-thick CuNi thin metal is 20 times that of a 3-μm-thick CuNi foil. In addition, Nissha’s processing process enables line / space = 20 / 20μm fine line patterning.

Using a high-resistance thin metal and narrowing the line width shortens the wiring distance between terminals of the strain gauge. The gauge can be narrowed.

| Setting conditions | Required terminal distance | |||

|---|---|---|---|---|

| Film thickness | Set resistance value | Line width | ||

| CuNi foil pattern | 3µm | 120Ω | 100µm | 73mm |

| NISSHA CuNi thin film pattern | 0.15µm | 120Ω | 20µm | 0.7mm |

It has been used as a pressure sensor for mobile terminals.

It can also be used for displays with touch panels, information devices, and game consoles.

Supports sensor customization for applications such as infrastructure deterioration diagnosis, load monitoring of cars and bicycles, and load cells.

Please feel free to contact us for any questions or consultations on film devices, including consultation on development, trial production, mass production consignment, etc.

CLICK