The diversification of electronic devices has led to a wide range of requirements for capacitive touch screens, including usage in harsh environments, compatibility with large displays, and adaptability to various shapes such as curved surfaces.

Touch screens for automotive applications require high reliability and durability.

Nissha’s touch screens enable long-term reliaibility and operation under high-temperature environments, utilizing anti-corrosion technology that protects the metal wiring. Furthermore, Nissha is certified for IATF 16949.

Technology details: Material technologies

Nissha’s touch screens utilize optically isotropic COP film, which minimizes the occurrence of rainbow and enhances visibility.

MidCell™ structure option utilizes polarizer film and minimizes reflections to maximize display clarity.

Technology details: Material technologies、MidCell™

Touch screen solutions tailor-made to meet customer’s specific needs, ensuring flexibility to accommodate customer’s preferences.

– Sensor

– Sensor + FPC + cover panel/glass (touch screen)

– Sensor + FPC + cover panel/glass + LCD (touch screen with LCD)

Technology details: Process Technology

| Product | Modue assembly options | Image |

|---|---|---|

| Sensor | Sensor |  |

| Sensor +FPC |

|

Touch screen | Sensor +FPC +Cover panel |

|

Touch screen with display |

Sensor +FPC +Cover panel +LCD/OLED |

|

Touch input with heavy gloves and water can cause touch input issues. Nissha touch screens can provide accurate touch input and can overcome these issues.

Technology details: Process Technology

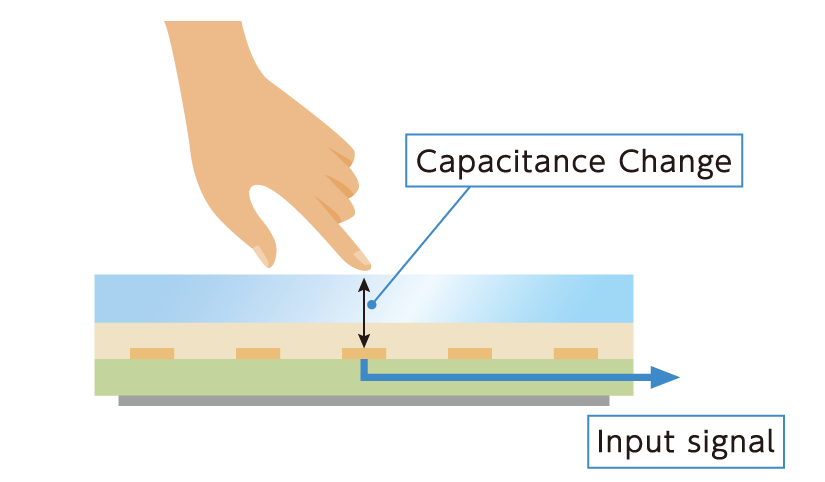

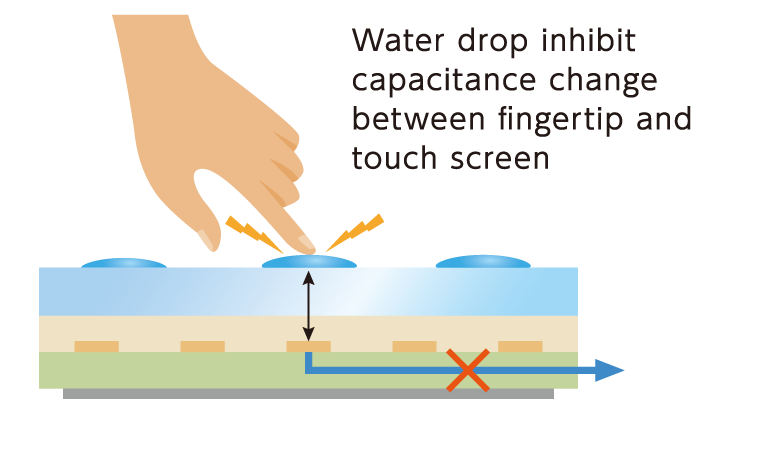

Capacitive touch screens operate by detecting changes in capacitance between the fingertip and the sensor. However, when the surface of the touch screen is wet with liquids such as water, noise can occur, leading to issues with signal detection.

The video below demonstrates test results showcasing the ability to prevent incorrect inputs and unintended reactions, even when water droplets are present on the touch screen’s surface.

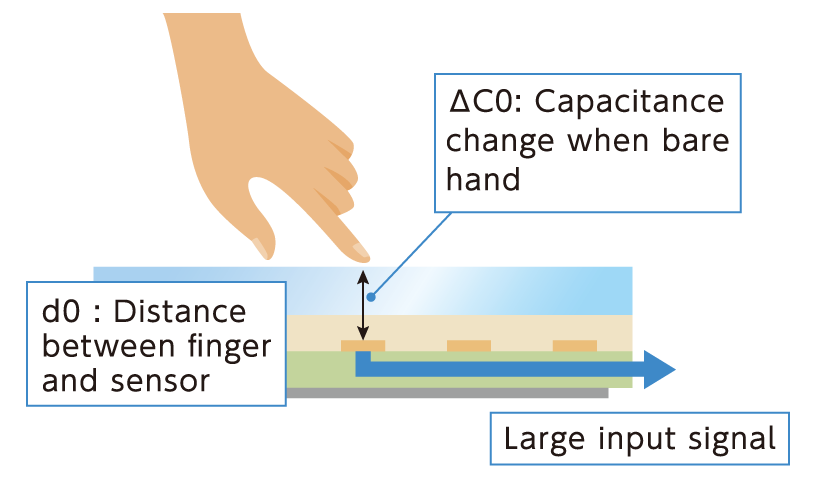

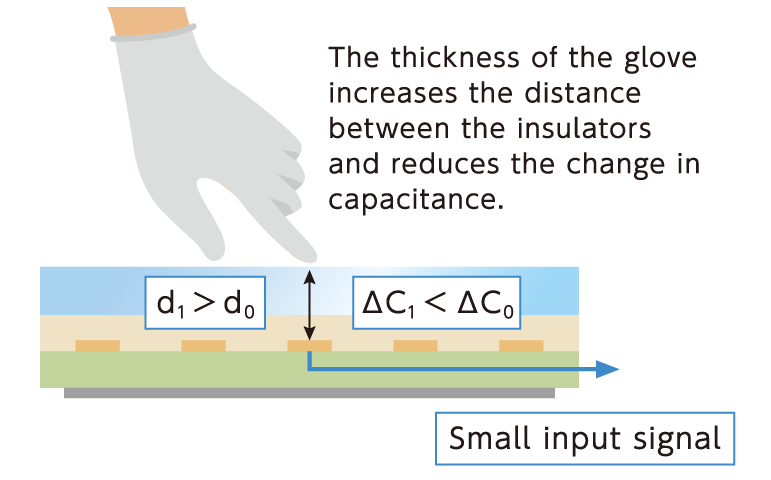

Gloves are made of insulating materials such as rubber or textile fabrics. When touch screens are input while wearing gloves, the distance of the insulator between the finger and the sensor increases, resulting in a weaker input signal.

The following video presents test results showing that input is possible even while wearing rubber gloves with a thickness of 2 mm or cloth gloves with a thickness of 1.5 mm. This technology ensures operation not only in industrial settings but also in medical applications and cold regions.

Examples of Use:

– Use in Medical Settings: Operating medical equipment while wearing rubber gloves

– Industrial Applications: Operating machinery in manufacturing sites or handling information terminals in cold storage warehouses.

– Outdoor Use in Cold Regions: Operating information terminals while wearing gloves in cold outdoor environments

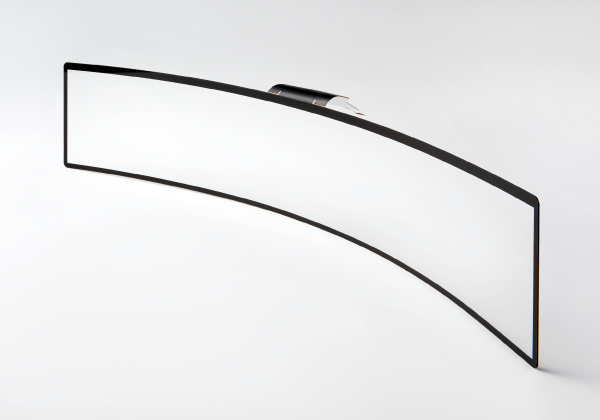

Glass touch screens had the drawback of being unsuitable for use on curved surfaces. However, Nissha’s touch screens, being film-based and flexible, can be laminated onto 2.5D curved displays.

Technology details: Process Technology

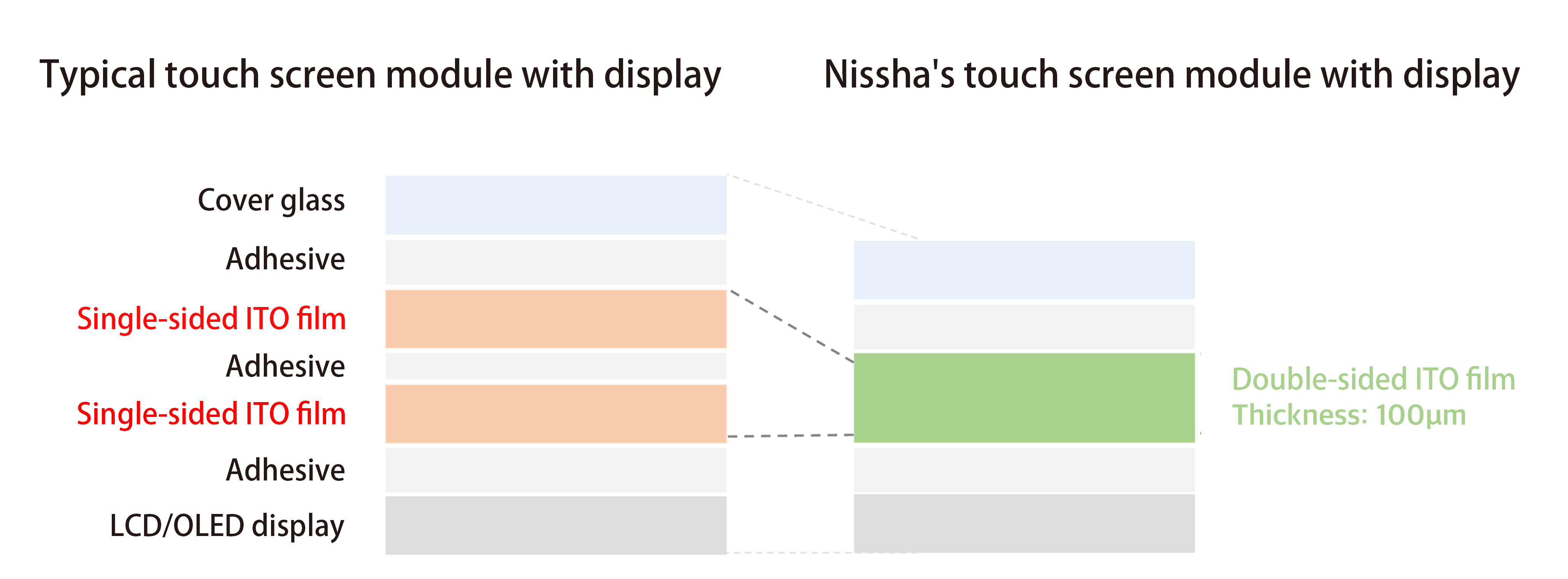

In a typical capacitive touch screen, the sensor is formed using two transparent electrode films, one for the X-axis and one for the Y-axis. Nissha has developed technology to form transparent electrodes on both sides of an extremely thin film with a thickness of just 100 μm. This allows us to introduce a touch screen that is thinner and lighter than conventional capacitive touch screens.

Technology details: Process Technology

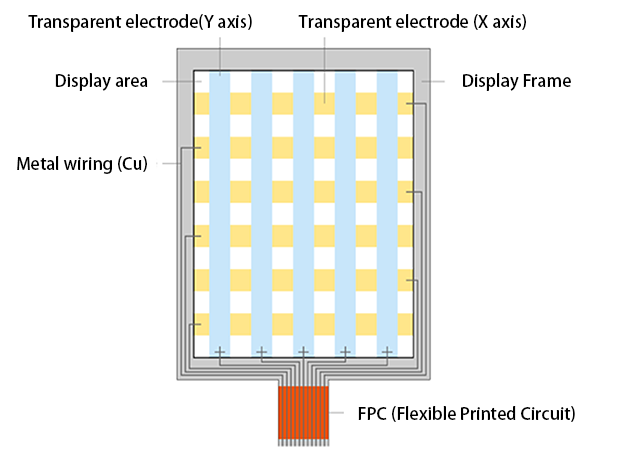

By narrowing the bezel of the touch screen, we contribute to maximizing the display area. Nissha achieves a narrower bezel for metal wiring (Cu) using advanced photolithography technology, enabling fine patterning with a Line/Space ratio of 10/10 μm. Furthermore, by patterning the transparent electrode (ITO) and the metal wiring (Cu) in a single process, it is possible to align them with high positional accuracy, allowing for even narrower bezels.

Technology details: Material technologies、Process Technology

Please feel free to contact us for any questions or consultations on film devices, including consultation on development, trial production, mass production consignment, etc.

CLICK