Customizable Touch Screen

Nissha Touch Screen TechnologiesNissha utilizes diverse technologies to provide touch screens tailored to our customers’ needs.

Nissha uses COP (cycloolefin polymer) as the base film for transparent electrodes.

COP material has high transparency and excellent visibility. Phenomenon such as rainbow under polarized sunglasses can be prevented due to isotropic material characteristics.

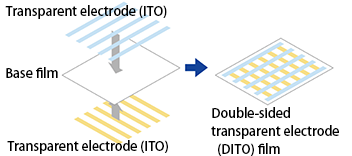

A conventional capacitive touch screen typically consists of two transparent electrode films (ITO films). In contrast, Nissha achieves a thinner and lighter touch screen design by utilizing a single “DITO film,” which has transparent electrodes formed on both sides.

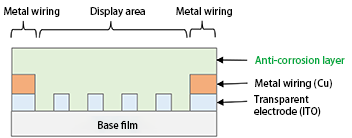

Nissha touch screens feature a corrosion-resistant layer that covers the metal wiring, to endure high-temperature and high-humidity environments. This corrosion-resistant layer is designed with optimal optical properties for touch screens, ensuring high reliability and delivering clear, vivid display quality.

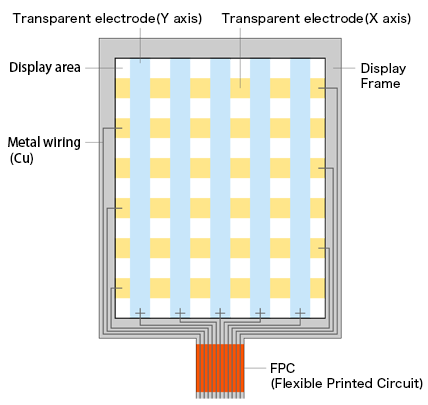

In general, touch screens are constructed by laminating two conductive films, each patterned with a transparent electrode (ITO) and a metal wiring(Cu) layer on one side. In contrast, Nissha touch screens utilize a single film with transparent electrodes (ITO) and metal wiring (Cu) layered on both sides. By performing the patterning process in a single step, we achieve high positional accuracy for both the electrodes, metal wiring, and top/bottom patterns.

This high positional accuracy maximizes the performance of the IC chip, enabling input under harsh environments (wet hands or heavy gloves). Additionally, improved alignment precision during processing allows for the creation of narrower bezels.

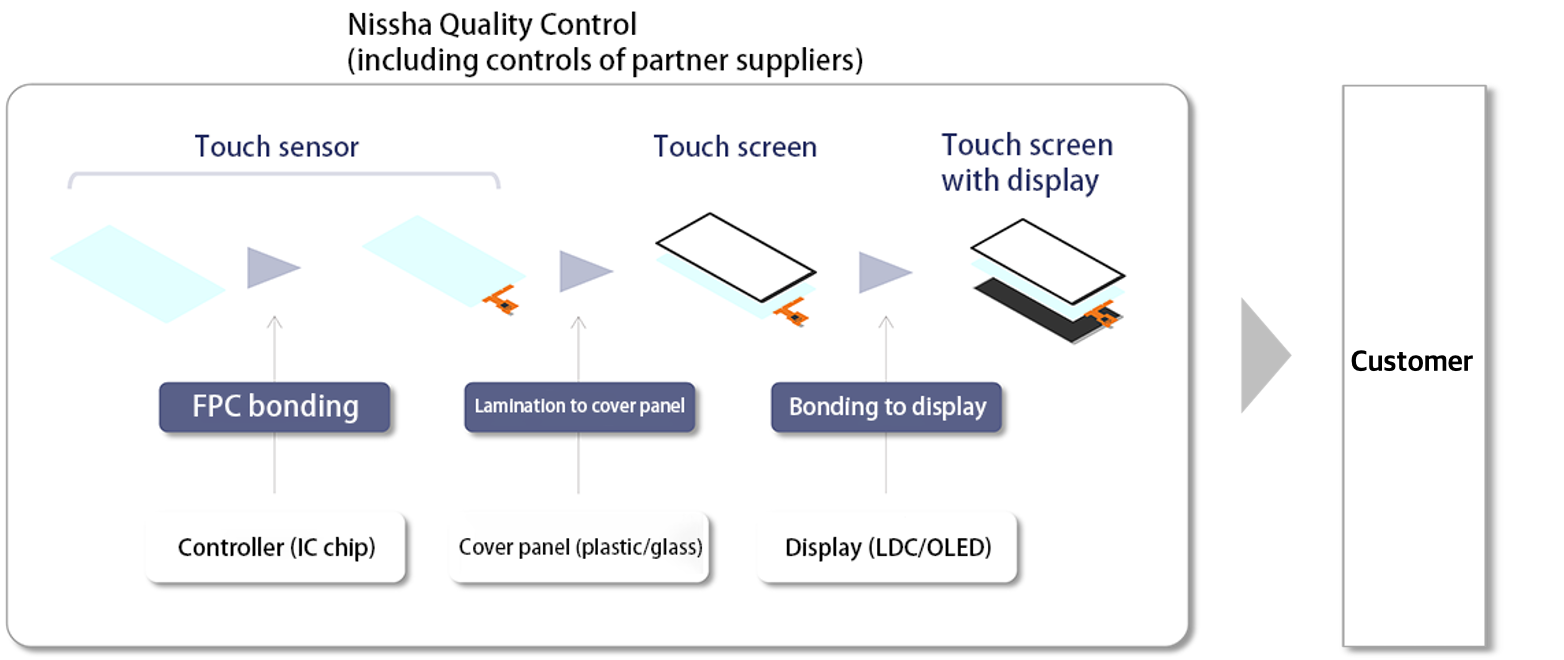

Nissha can provide the following processing options for sensors, offering flexible customization to meet customers’ requirements.

– FPC bonding

– Lamination to polarizers, glass panels, or plastic panels (also to 2.5D curved cover panels)

– Direct bonding to displays

Please feel free to contact us for any questions or consultations on film devices, including consultation on development, trial production, mass production consignment, etc.

CLICK