Friction/shear force sensor

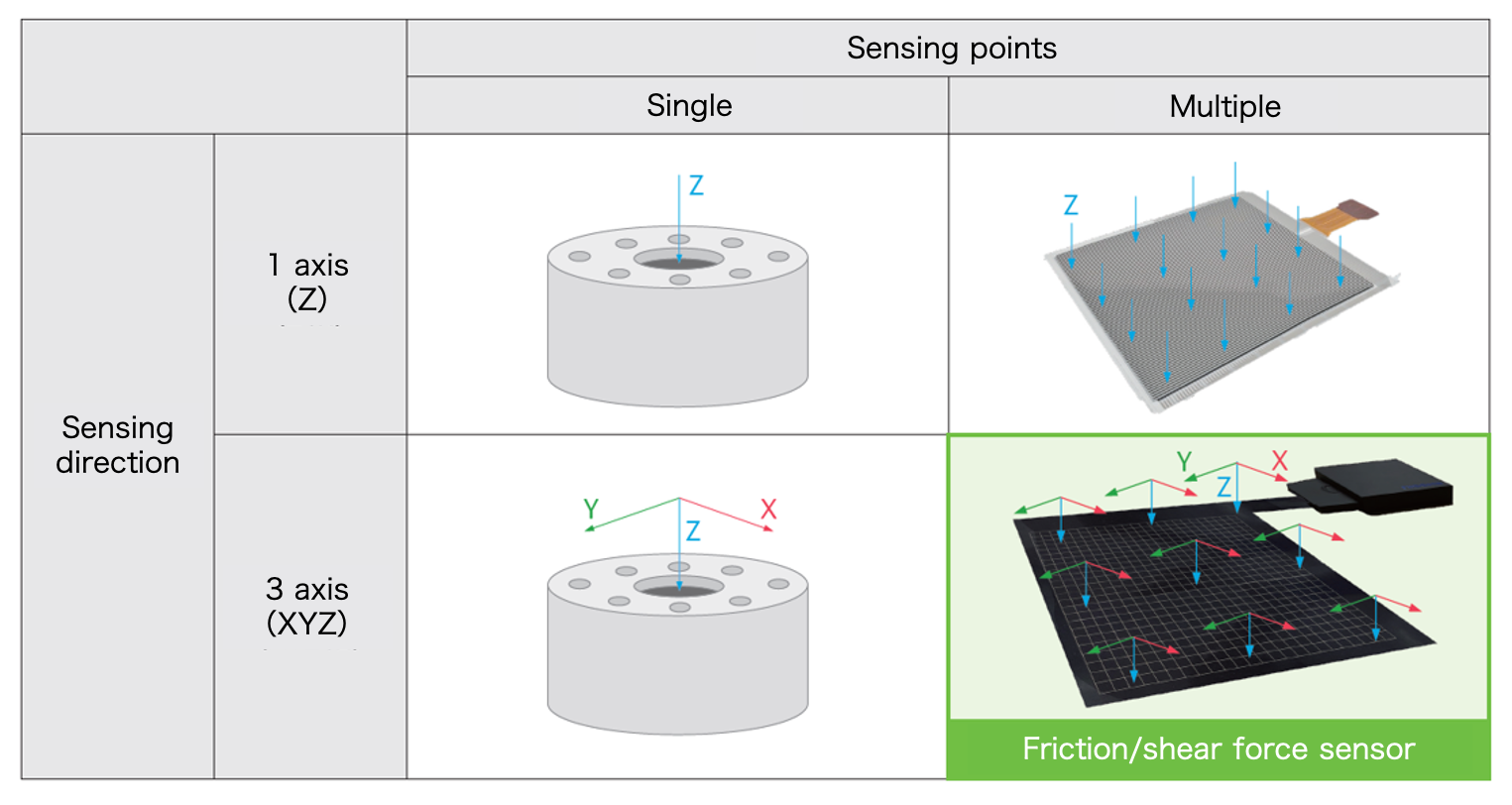

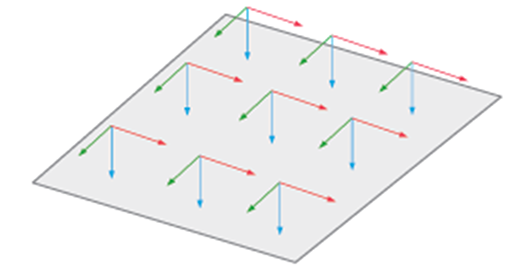

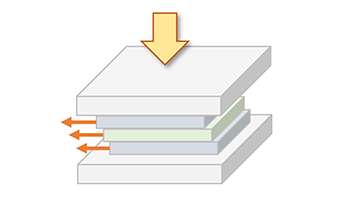

Nissha has developed the sheet -type sensor that maps the in-plane distribution of friction and shear force by detecting deformation of the sensor surface.

The sensor delivers solutions to users in the following needs;

・Multi-location pressure mapping

・3-axis pressure mapping

・Quantification of tactile sensation

The array sensing elements on the sensor substrate enables multi-location detection at the same time. The sensor measures not only Z-axis pressure but also X-axis and Y-axis pressure.

The film sensor is thinner and lighter than load-cells. It is also flexible and applicable to curved surfaces.

The sheet-type sensor provides a flat surface while placing multiple load-cells provides a irregular and bumpy surface.

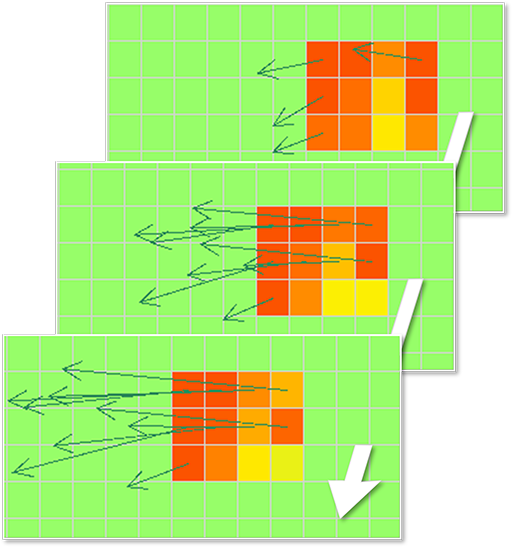

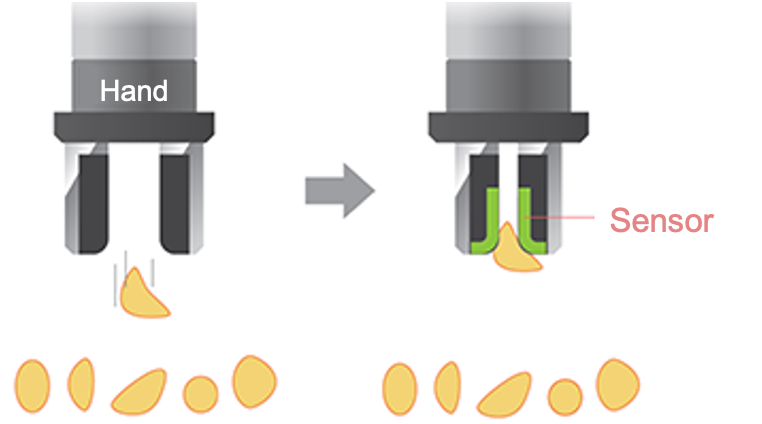

The sensor embedded in the robot hand prevents an object from slipping out.

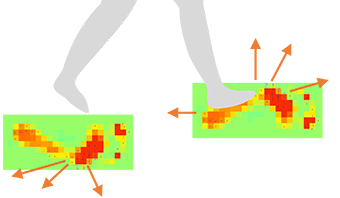

Change in direction and magnitude of friction can be observed when the foot hits the floor or the ground.

The shear force measurement may help visualize the cause of manufacturing process defects and tacit knowledge of skilled workers, leading to process improvements and automation, respectively.

Pressure mapping in various scenes, such as tire contact and seating.

3-axis input device as a new user interface.

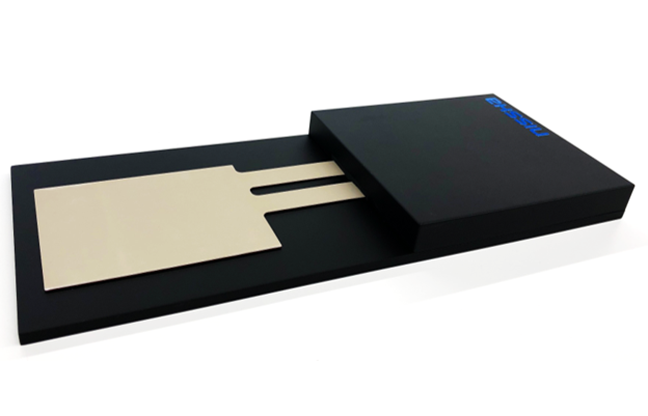

| Friction/shear force mapping system RK1A (Small) |

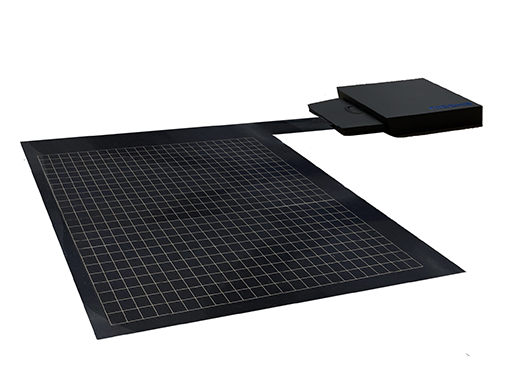

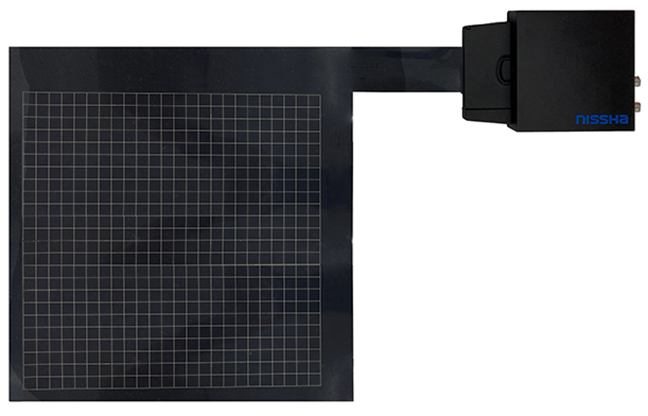

Friction/shear force mapping system 310S (Large) |

|

|---|---|---|

| Product image |

|

|

| Sensing area size | 44 ✕ 66mm | 312 ✕ 312mm |

| Availability | Rental & for sale | Market release in Dec. 2024 |

| Page |

Please feel free to contact us for any questions or concerns.

InquiryCompared to conventional sensors, it can measure friction and shear force at multiple locations at once.