Quality control and manual task automation

Finding the cause of defects in manufacturing process, quantifying and visualizing the skilled techniques, and automation of manual processes.

Application scenarios

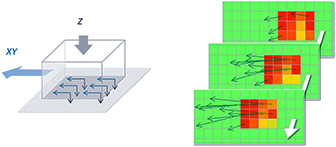

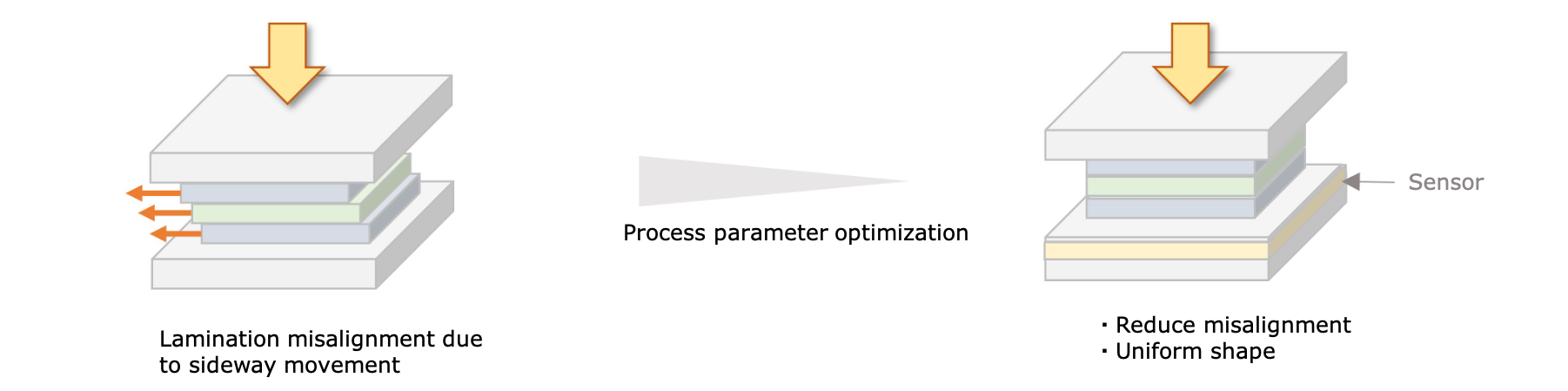

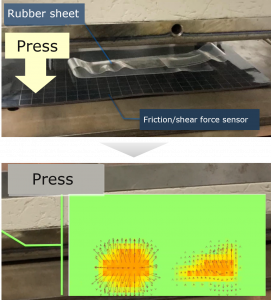

Visualization of misalignment during press lamination

Measure grindig shear/friction force

Measure grindig shear/friction force

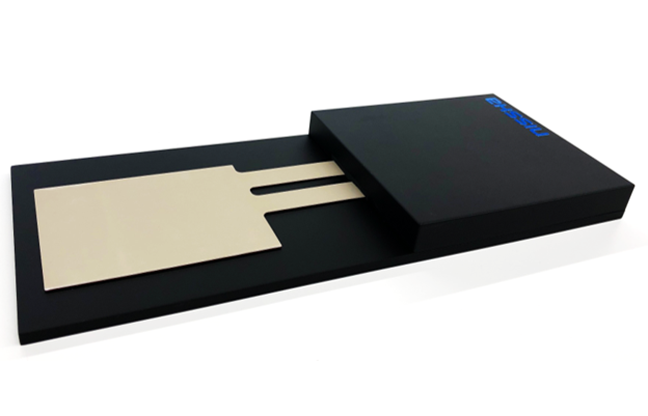

| Friction/shear force mapping system RK1A (Small) |

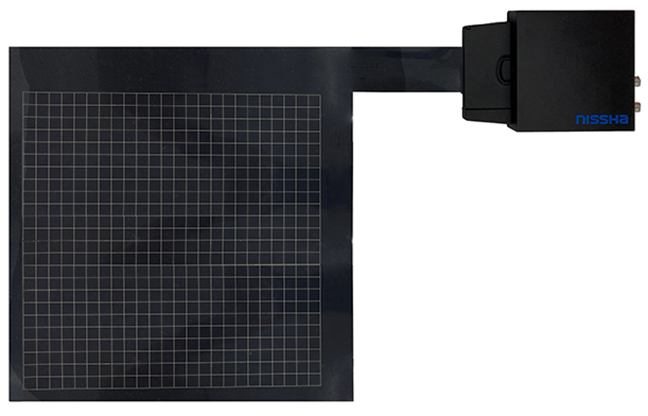

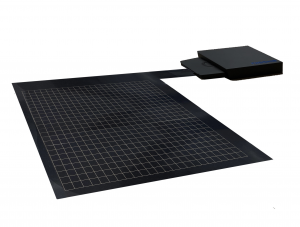

Friction/shear force mapping system 310S (Large) |

|

|---|---|---|

| Product image |

|

|

| Sensing area size | 44 ✕ 66mm | 312 ✕ 312mm |

| Availability | Rental & for sale | Market release in Dec. 2024 |

| Page |

This product is a measuring device and is not classified as a medical device.

Real-time visualization of shear force occured in manual processes such as polishing and sewing for your processes automation. Data acquired during press and roll processes would help us find the root cause of misalignment.

Measuring 3-axis force distribution helps us identify subtle abnormalities contributing to the processes automatio and the process quality improvement.

The film-based sensor is thin and lightweight that can be applied not only to flat surfaces but also to curved surfaces.