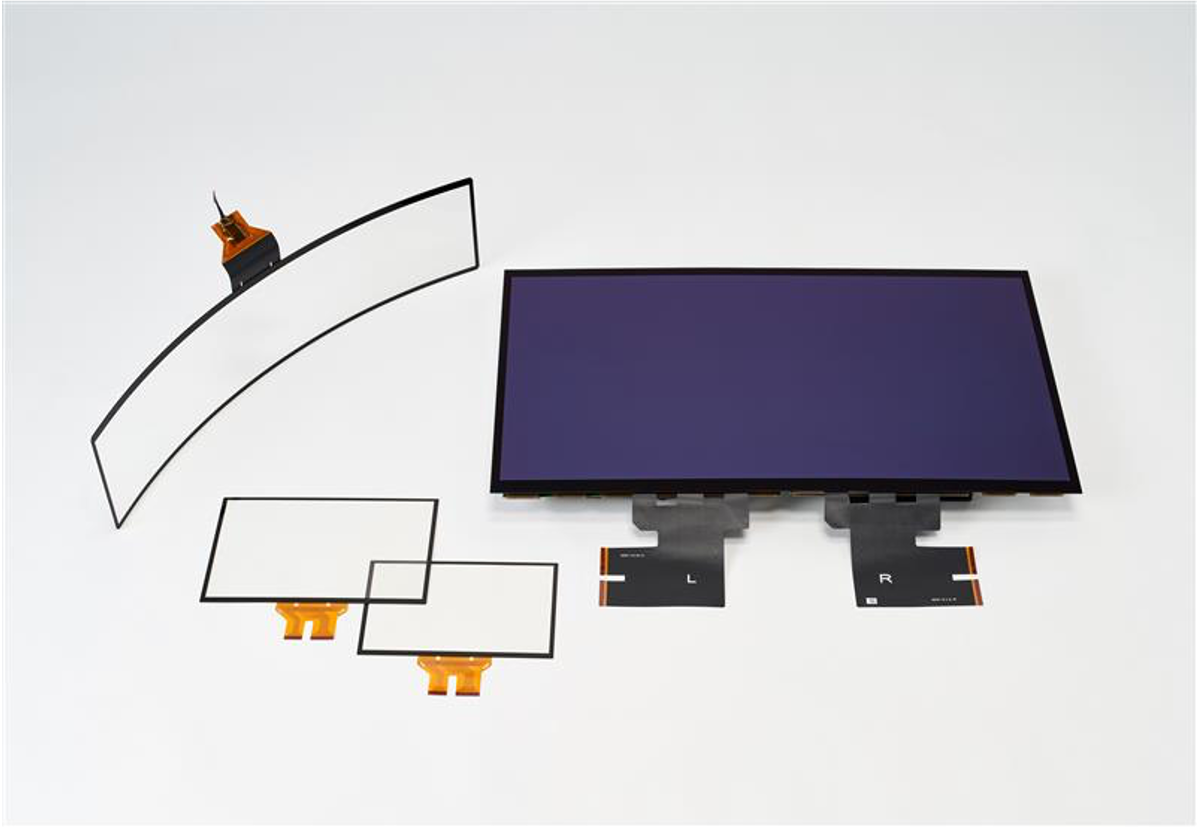

Nissha’s film touch screens offer high reliability and excellent optical properties. We have roll-to-roll manufacturing capabilities and production capacity to support high-volume output.

We supply touch screens for automobile displays, industrial devices, tablets, game consoles, and other industries. We also provide module integration services by laminating our touch screens to cover panels, displays, etc., tailored to meet customer requirements.

Please feel free to contact us with any inquiries or consultations on touch screens, including development, prototyping, and mass production arrangements.

– Passes automotive/industrial grade reliability

Support from cradle to grave with dedicated project team

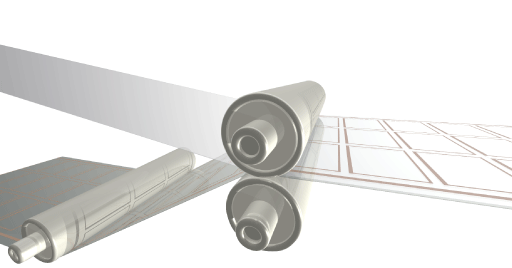

Mass production technology

Stable production with high processing accuracy and minimal quality variation achieved through roll-to-roll mass production technology

Procject management

Dedicated project team to provide seamless support from design review and prototyping to mass production

Prompt support

Prompt support to meet meet automotive and mobile industry requirements

Please feel free to contact us for any questions or consultations on film devices, including consultation on development, trial production, mass production consignment, etc.

CLICK