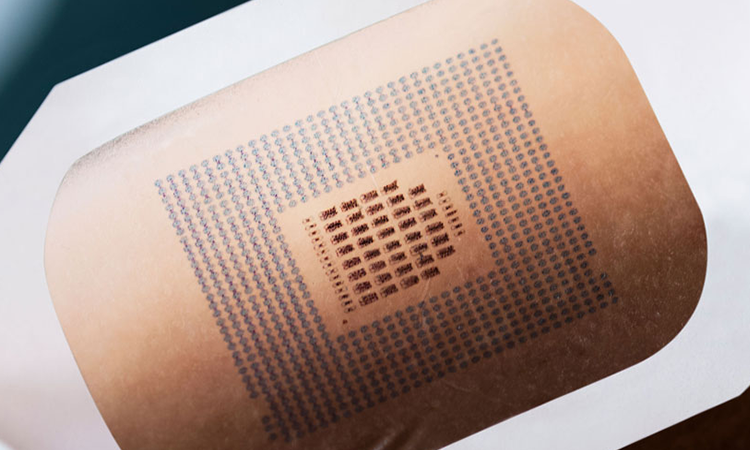

Leveraging our ISO 13485 based quality systems and expertise in processing techniques and strong capabilities in quality control, we support the development and manufacturing of endoscopic instruments used for minimally invasive treatment, biocompatible medical devices (both bioabsorbable and non-bioabsorbable), and biosensors.

Services

By bringing together Nissha Group’s technologies, we provide integrated design,

development, and manufacturing services for the medical device field.

Contract Manufacturing Service

- Outsourcing manufacturing to focus internal resources on R&D

- Building a globally competitive mass production system

- Strengthening the supply chain to ensure stable product supply

Our Kyoto facility is equipped with Class 10,000 cleanrooms and operates under ISO 13485. In addition, our on‑site Innovation Center enables a seamless transition from engineering to manufacturing.

We also operate multiple manufacturing sites globally, supporting medical device production for international markets.

Contract Development and Manufacturing Service

- Proposing optimal processing methods

- Recommending optimal materials and material combinations

- Establishing manufacturing system that supports global market expansion

We manage cost and schedule with regulatory requirements in mind to ensure a smooth approval process.

Solutions

- Providing cutting-edge technology

- Handling a wide range of materials, including plastics, rubbers, metals and biomaterials

- Contributing to improving the quality of life (QOL)

At Nissha, our dedication to design and user experience allows us to deliver functional medical devices with exceptional attention to details.