In recent years, materials that are degraded and absorbed in the living body, so-called “bioabsorbable materials,” have attracted attention in the medical field, and are widely used. Bioabsorbable materials that enhance the quality of medical care and contribute much to improve the QOL (quality of life) of patients. In this column, we will discuss what bioabsorbable materials are, and for which devices these materials are used.

A "bioabsorbable material" type of biocompatible material

Materials as components of medical devices that are in contact with the skin or inserted into the body in the medical field are required to be “biocompatible.”

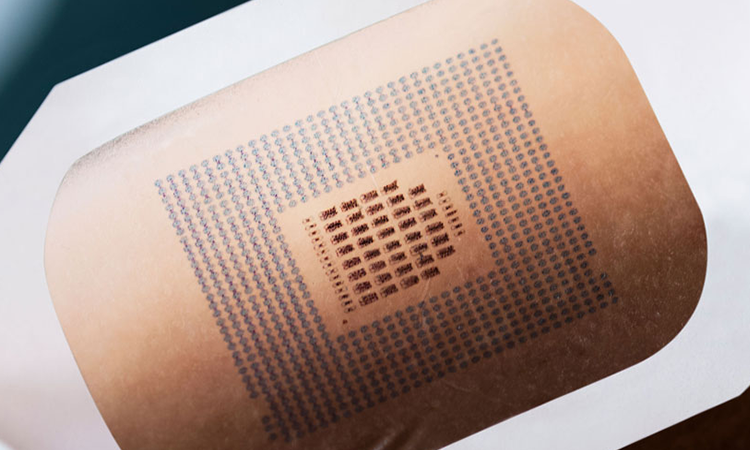

Nissha is also engaged in contract manufacturing and contract manufacturing and development of medical devices that use bioabsorbable materials as one of the biocompatible materials.

Here, we briefly explain the nature of biocompatibility and the biocompatible materials.

What is biocompatibility?

Biocompatibility is “the nature of being not recognized as a foreign body by the living body, and not be rejected, and then existing in harmony with the living body when being attached or implanted.” Materials with low biocompatibility are recognized as a foreign body, resulting in foreign body reactions and rejection reactions.

Since foreign body and rejection reactions may cause thrombus-formation or inflammation, and some of these reactions may be carcinogenic, biocompatibility is very important, especially for medical devices that will be implanted in the body.

What are bioabsorbable materials?

Biocompatible materials that are degraded and absorbed in the body are called “bioabsorbable materials.” Since such materials are often used for medical devices to be implanted into the body for their characteristics, and have the following advantages, they contribute to improvement in QOL.

- No need for measures to remove the product after surgery, and can reduce the pain of the patient

- Not implanted in the body for a long period, and highly safe

- Can adapt to the growth of a child whose body size is changing

- etc

Bioabsorbable materials are subject to more stringent conditions because they should be biocompatible before degradation and their degradation products should be safe as well.

Requirements for bioabsorbable materials

Materials that are used as a bioabsorbable material should pass the following conditions:

- Materials before degradation should have superior biocompatibility

- Degradation products are non-toxic,and are metabolized/excreted

- Have adequate mechanical properties

- Degraded and absorbed at appropriate timing

- Can be molded to any shape

Types of bioabsorbable materials

There are mainly three types of bioabsorbable materials.

These are selected according to the intended use of the medical device.

Natural polymers

While these are polymers derived from humans and animals, and are highly biocompatible and absorbable, they may cause antigenic anaphylaxis or infections.

Main natural polymers

Collagen, hyaluronic acid, alginic acid, gelatin, chitin, chitosan, carboxymethylcellulose (CMC), glycosaminoglycan, fibrinogen, etc.

Synthetic polymers

Artificially-made synthetic polymers had issues with absorption and compatibility compared to naturel polymers. Recently, materials to solve these issues have been developed, and have been widely used for medical devices.

Main synthetic polymers

Polylactic acid, polyglycolic acid, polycaprolactone, polydioxanone, L-lactide-ε-caprolactone copolymer, lactic acid/glycolic acid copolymer, etc.

Inorganic materials

Mainly used for the treatments of bone and tooth defects.

Main inorganic materials

Tricalcium phosphate, carbonate apatite, etc.

Magnesium has been noteworthy as a bioabsorbable metal recently, and the R&D for this metal has been advanced.

Magnesium has bioabsorbable properties, but is also a metal, so it is characterized by higher strength than resin.

There are high expectations of its application to the fixation of bones and joints, suturing equipment, and stents.

Please leave the processing of bioabsorbable materials up to Nissha

Nissha is engaged in the manufacture/development of medical devices using bioabsorbable materials that are helpful to improve QOL.

We can help with requests from doctors. If there is, for example, a problem with an existing medical device and the doctor wants to improve it, has an idea what needs to be done, but does not know how to realize it practically, you can depend on us to help.

Examples

Feel free to ask us about medical injection molding.