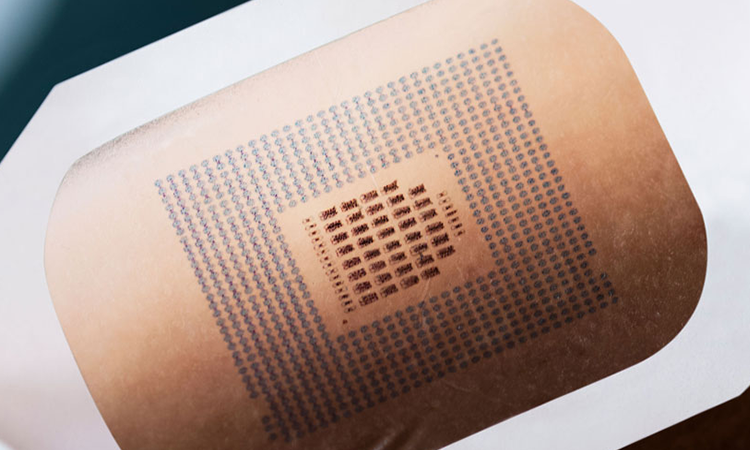

We have various track records of transactions with top global medical device makers,

and keep being selected as a partner in the development and manufacture of medical devices.

Our advantages

-

- World-class creative technical capabilities

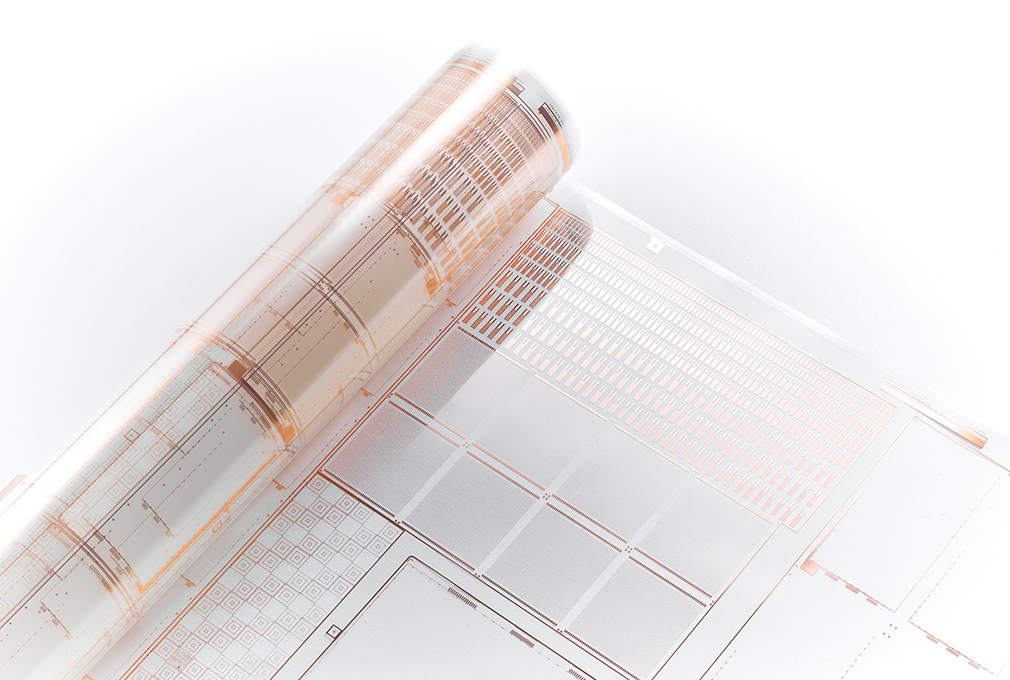

- We have technical capabilities to promote the development of devices leading the world. For example, our advanced sophisticated film technology has been expanding a strong share in the IT prducts market. We can stably provide high-performance/sophisticated products with our innovative “six core technologies”.

“Six core technologies” of Nissha

-

- R&D system at the Innovation Center

- Nissha Innovation Center KYOTO (NICK) is an R&D facility on the premises of the Kyoto Headquarters. NICK has a cross-functional R&D system integrating experienced engineers and the latest prototype/analysis equipment.

We propose development programs corresponding to projects, such as linkage with external organizations and use of public business support funds.

A manufacturing site is also attached to the premises of the Kyoto Headquarters (in accordance with ISO13485), which enables smooth transfer to mass production.

-

- Support for overseas expansion

- We have 11 manufacturing sites of medical devices in Japan, Europe and the U.S., and can propose global supply chains when requested by customers. Especially for the U.S. market, the factory in the Dominican Republic takes the role of mass production, with two factory buildings (a total area of 9,800m2) and 400 or more workers, which is highly competitive on the international market in both quality and costs. We can also make proposals in regions not covered by our affiliates, through alliances with partners in Japan and overseas (Ex.: making alliances with partner companies for manufacturing in Southeast Asia and selecting partners for regulatory affairs applications).

Medical device

manufacturing site