Nissha's six core technologies - printing, coating, lamination, molding, patterning and metal processing - are contributing for the manufacture of medical devices. These manufacturing technologies help to improve/advance QOL (quality of life) by realizing comfortable designs for users.

-

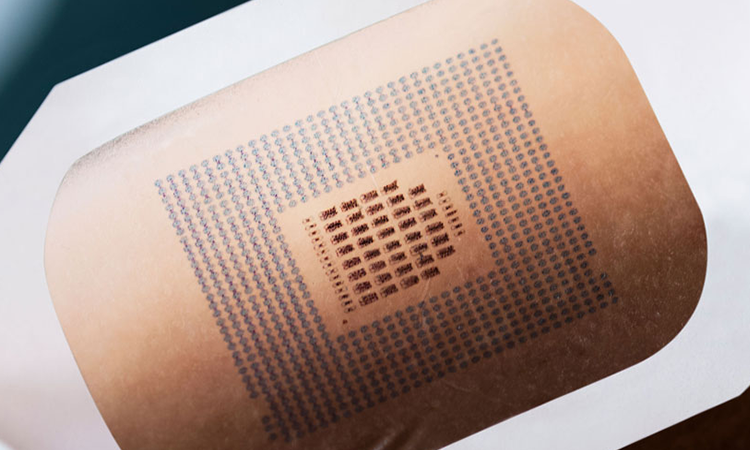

Micro Molding

As medical devices become smaller and medical robots evolve, there is an increasing demand for even smaller and more precise components. Isometric, a member of the Nissha Group, offers high-precision molded products through its unique mold and molding processing technology.

-

Bioabsorbable materials

Bioabsorbable materials that have been widely used in medical care in recent years. We have contracts of manufacturing/development of medical devices using bioabsorbable materials that help to improve/advance QOL.

-

Injection Molding for Medical Devices

NISSHA’s unique plastic injection molding technologies are able to use for medical devices. In-mold decoration and In-mold labeling provide various decorative and functional plastic molding components.