We always hear about “ISO13485” when we are involved in the manufacture, development, and sales of medical devices. ISO13485 is an international standard that stipulates the mechanisms necessary to ensure the quality of medical devices, such as “Medical Devices – Quality Management Systems – Requirements for Regulatory Purposes”. In this column, I will explain what a ISO13485 is.

What is ISO?

What exactly is “ISO”?

ISO is the abbreviation of “International Organization for Standardization,” a non-governmental organization in Switzerland that creates ISO standards for common use worldwide.

The standards created by the ISO are called the ISO standards. They allow smooth global business by ensuring that products of equivalent quality and level are provided all over the world.

They are international standards; the member countries (167 countries in the world including Japan [as of 2022]) vote for the creation and revision of the standards.

There are two major types of ISO standards. These are standards for the product itself, and those for the systems that manage the quality and environmental activities of the organization (management system). The ISO9001 quality standard is especially well known among the management system standards; it is a versatile standard to be applied to product control for a variety of products, but some parts of it could not cover all product fields.

Specific contents based on ISO9001 were thus added to create sector specifications. Among these standards, ISO13485 is specific to medical devices.

What is ISO13485?

ISO13485 is a sector specification for the quality management systems of medical devices among the abovementioned. The aim is to continuously ensure the safety, efficacy and stable quality of the medical devices.

This standard specifies the requirements of the quality management system that organizations related to one or more of the life cycle stages of the medical device, including design/development/manufacture, storage and distribution, installation, ancillary services and final discarding/disposal of the medical device as well as design/development and the provision of related activities.

The contents are based on ISO9001:2008, with the following seven items added as requirements for medical devices:

- Medical device file

- Cleanliness of product

- Installation activities

- Ancillary service activities

- Specific requirements for sterile medical devices

- Complaint handling

- Reporting to the regulatory authorities

Certification of ISO13485 requires the arrangement of an in-house system and the preparation of documents to achieve the requirements and internal audit for the operation in line with documents/retention of documents; and the applicant should undergo inspection by a supervisor, and then pass review by a third-party certification organization.

Certification takes some effort and time, but marketing authorization holders and manufacturers can definitely design, manufacture and launch medical devices that meet their intended use consistently by introducing ISO13485 and complying with the standard.

More and more countries have decided that ISO13485 should be certified when doing business with medical devices overseas, including Europe, and the importance of ISO13485 is increasing, especially for the business of medical devices associated with overseas exports.

Relationship with the QMS Ministerial Ordinance

In Japan, registration as a “manufacturer” is necessary to manufacture medical devices, and approval of the “manufacture and sales” is necessary to manufacture and sell medical devices. “QMS Ministerial Ordinance (Ministerial Ordinance on Standards for Manufacturing Control and Quality Control of Medical Devices and In-vitro Diagnostics)” describes matters to be observed for the registration or approval of these “businesses.” The “QMS Ministerial Ordinance” is for the addition of regulatory requirements for Japan to ISO13485:2016, and marketing authorization holders should undergo “QMS Compliance Inspection” to obtain approval and certification of their products. Certification of ISO13485 may be exempted from on-site inspections for QMS Compliance Inspections, etc. or from some of the inspections.

Just rely on Nissha with ISO13485 certification for the

manufacture of medical devices

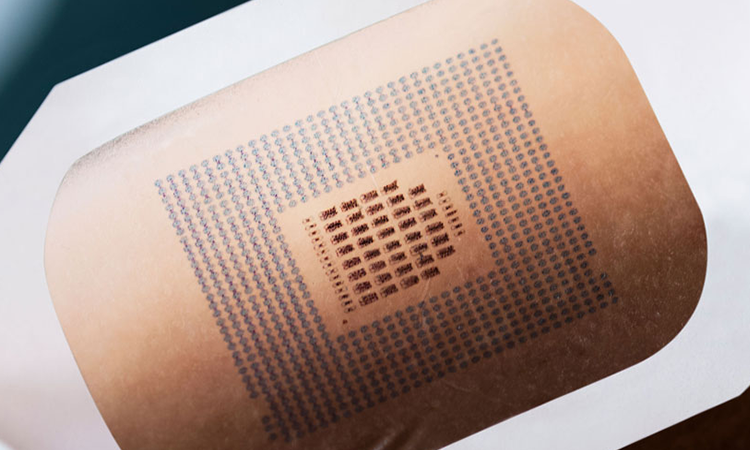

Nissha has manufacturing sites with ISO13485 certification in Kyoto, and overseas in the U.S., the Dominican Republic, France, the U.K., Malaysia, China, etc.

We can also respond to various needs of customers owing to the management of manufacturing environments suited for the characteristics of products, and our long-term processing achievements and the assembly of various materials in clean rooms.

Please contact NISSHA if you look for a manufacturer of medical devices.