The characteristics of this case are as follows.

- In-mold decoration : molding and design printing

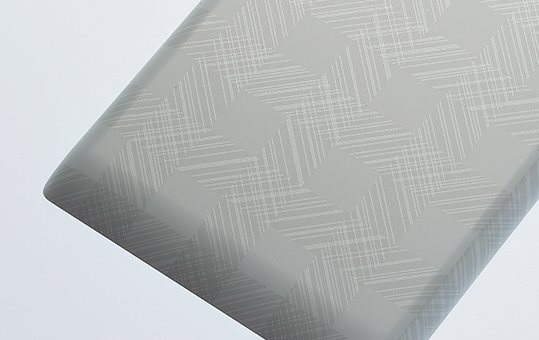

- Various graphic design by transfer foils

- Clear plastic molding for display

Various graphic design by transfer foils

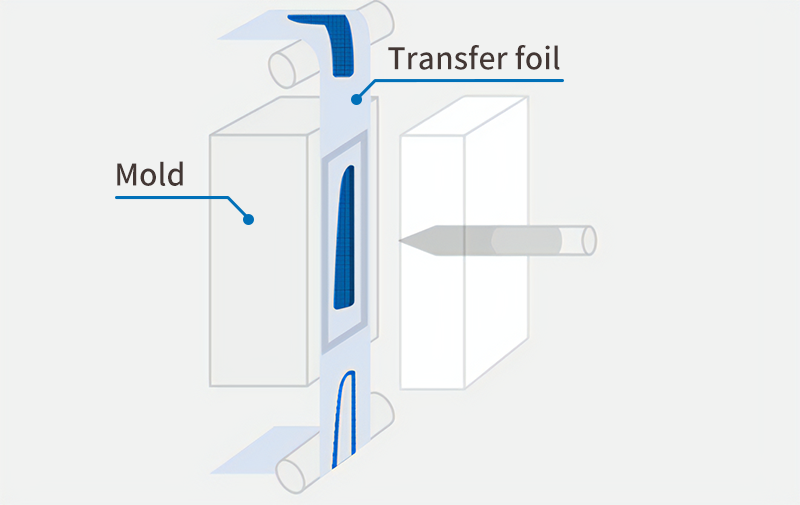

IMD (In-Mold Decoration) is a technique where a design printed transfer foil film is loaded into a mold, and the design is transferred onto the surface of the molded product during injection molding.

Transfer foils are manufactured through multicolor printing using gravure printing. Also, metallic gloss colors can be processed using aluminum vapor deposition. With such multicolor processing technology, the range of design possibilities greatly expands.

- Geometric patterns

- abstract designs

- metallic hairlines

- metallic colors such as gold and silver

IMD (In-Mold Decoration) technology is suitable for the production of a variety of cover panels.

Furthermore, it is also possible to achieve surface designs that incorporate tactile sensations such as “smoothness,” “moisture,” and “softness.”

Additionally, at Nissha, we have an in-house design department and a system in place to propose original designs that reflect our customers' voices.

-

Metallic hairlines -

Metallic gross -

Abstract design -

Carbon design -

Softness tactile -

Smoothness tactile

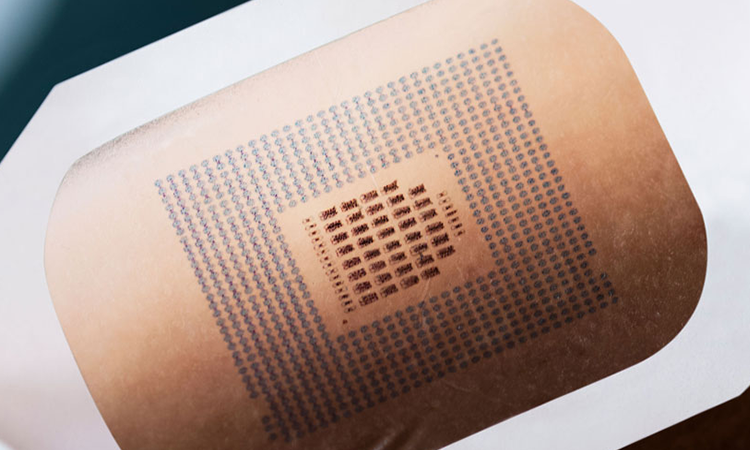

IMD (In-Mold Decoration) realises one-stop manufacturing of decorated molded products

IMD (In-Mold Decoration) is a technology that provides molding and printing in one stop.

Not only the graphic patterns of the display window frame, but also product logos and button marks can be transferred at the same time as molding.

In addition, by printing the frame part on the molded product surface, a seamless shape without steps can be achieved. As a result, it has become possible to provide hygienic products without dust accumulating in the steps.

Clear plastic molding for display

In IMD (In-Mold Decoration), by combining transparent resin molding and decorative transfer, display window frame parts can be manufactured in a single process. In other words, display panels can be manufactured with a simpler process than two-color molding.

Additionally, a hard coat layer is provided on the transfer foil surface, allowing us to offer display panels with excellent scratch resistance.

Furthermore, the transparent window part is manufactured considering optical characteristics. Optical specs required as display characteristics, such as welds and retardation, are quality checked during the design and manufacturing stages to meet customer requirements.

Contract manufacturing supplier of plastic parts for medical devices

At Nissha, we accept consultations for contract manufacturing of plastic parts for medical devices.

We have a support system in place for all phases, from design considerations and prototype requests to mass production consultations.

If you have any inquiries about the planning, development, and manufacturing of medical devices, please do not hesitate to contact us.

製造拠点Production sites

アジアAsia

成形工場Molding site

- 中国・昆山(Kunshan)Kunshan, China

- 中国・広州(Guangzhou)Guangzhou, China

- マレーシアMalaysia

印刷工場Printing site

- 日本・甲賀Koka, Japan

北米North America

成形工場Molding site

- ミシガン州・VicksburgVicksburg (MI), USA

- メキシコ・San Luis PotosiSan Luis Potosi, Mexico