Quality is very important for medical devices that are used to treat and prevent illnesses, and that affect the health of users. The effect of highly controlled medical devices that are inserted into the body are particularly huge, and may be life-threatening. Manufacturing environments are crucial to the manufacture of such medical devices with stable quality, and many of these devices are manufactured in a clean room. This column explains what a clean room is, clean room levels, and how to control clean rooms.

What is a clean room?

Clean room is “a space where airborne microparticles and airborne microorganisms are controlled under a set level of cleanliness, and impurities and dust should be removed from any article that is brought into the space and dust should not be brought into the space.”

Microparticles mean small particles of 0.5 μm in size that cannot be seen unaided with the naked eye.

Ideas and dedicated equipment are required from the stage of designing the room to prevent such microparticles.

Methods such as the use of a filter, airflow control, and keeping a positive pressure in the room are adopted.

The temperature/humidity is controlled at a constant level in clean rooms.

Failure to maintain the temperature or humidity may adversely affect product quality, or make operators sweat, which may become attached to the product.

Clean room levels

Clean rooms are classified based on the level of cleanliness.

The following three standards are used: USE Fed.Std.209E(U.S. Federal Standard), ISO14644-1 (International Organization for Standardization), and JIS (Japanese Industrial Standards).

Currently, the ISO is used as the international uniform standard. The FED standard was abolished, but it had been used for a long period of time and is still used customarily.

The FED standard specifies the cleanliness based on the number of microparticles greater than or equal to 0.5 um present per cubic foot (approximately 30.5 cm square).

| Cleanliness under the FED standard |

Number of microparticles of 0.5µm/f3 |

Equivalent to ISO/JIS standard |

|---|---|---|

| Class 1 | 1 | ISO 3 |

| Class 10 | 10 | ISO 4 |

| Class 100 | 100 | ISO 5 |

| Class 1,000 | 1,000 | ISO 6 |

| Class 10,000 | 10,000 | ISO 7 |

| Class 100,000 | 100,000 | ISO 8 |

The required level of cleanliness varies depending on the type of industry.

Clean rooms of relatively low cleanliness are used for automobile parts and printing plants. Semiconductor plants implementing nanometer-level processing require a very high level of cleanliness.

| Type of industry | Required cleanliness level |

|---|---|

| Semiconductors | Class 1-100 |

| Electronic components | Class 100~10,000 |

| Optical equipment | |

| Precision machinery | |

| Chemicals | Class 100~100,000 |

| Foods | |

| Printing | Class 1,000~100,000 |

| Operating room | |

| Automobile parts |

Maintenance and control of clean rooms

Operation and regular check of daily usage rules are important for the environmental control of clean rooms.

The following are the “four principles” for clean rooms:

-

- Do not bring anything in

- Wear clean suits covering the whole body and gloves, remove dust by washing the hands, lint roller or sticky mat, and then take an air shower before entering the clean room. The procedure for entering the room is strictly specified, and operators must follow it. Tools, apparatuses and materials to be brought into a clean room should pass through a double-door carry-in entrance equipped with an air shower called a pass box.

-

- Do not generate anything

- Human beings are the main source generating dust. It is important to wear a clean suit first.

In addition, parts that are likely to generate dust may not be brought into the clean room.

Paper and cloth specialized for use in clean rooms should be used.

-

- Do not let dust accumulate

- Rooms should be regularly cleaned with a layout for easy cleaning so that the dust is not likely to accumulate.

Dust is most likely to accumulate on the floor. Avoid placing products directly on the floor, but put them at a height above the waistline (60 cm) or higher if possible.

-

- Remove

- Promptly remove all unnecessary items and place only essential items.

A ventilation route is provided to discharge floating substances out of the room by air flow. Local ventilation is also effective in places with a large amount of dust. - It is important to make rules for these principles and conduct daily control to maintain a clean environment for a clean room.

Microparticles in the air are measured by monitoring the temperature and humidity or particle counter to check whether the environment is definitely maintained.

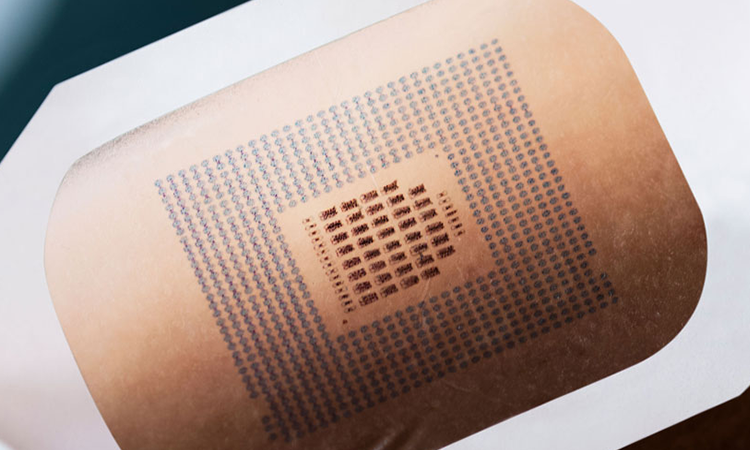

You can rely on Nissha for the manufacture of medical devices in a clean room

NISSHA has multiple manufacturing sites with clean rooms of Class 10,000 (ISO class 7) in Japan and overseas. We also have a long history of processing and the assembly of a variety of materials in clean rooms. Please contact NISSHA if you need a clean environment for the manufacture of a medical device.