- Meeting the Demand for Miniaturization and Precision in Medical Device Components

- Providing high-precision molded products with proprietary mold and molding technology

- Proven track record in various medical devices, including endoscope tip components and optical lens parts

As medical devices become smaller and medical robots evolve, there is an increasing demand for even smaller and more precise components. Isometric, a member of the Nissha Group, offers high-precision molded products through its unique mold and molding processing technology.

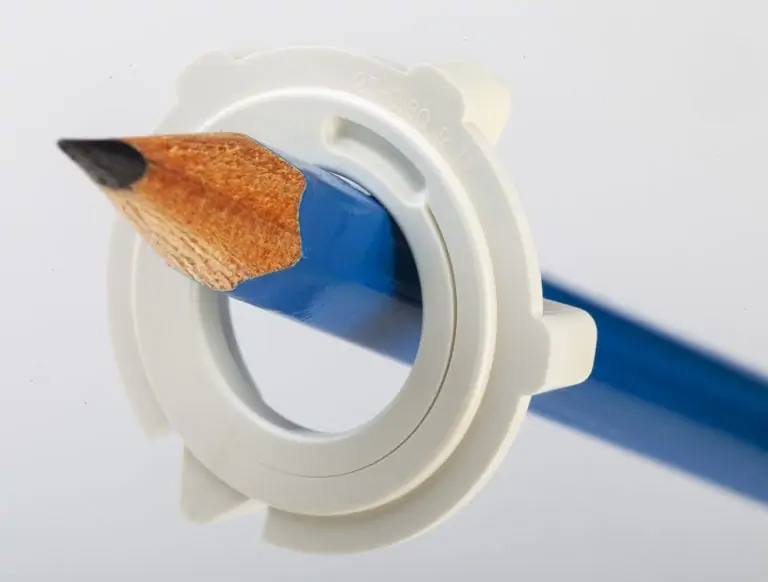

Offering Micro Parts for Medical Devices

-

Miniaturization and precision enhancement through micro molding

Micro molding is a technology that precisely molds extremely small parts at the micron level. Using injection molding, it is possible to mass-produce small parts with high precision and stable quality.

-

Specialized Mold and Injection Molding Machines for Micro Molding

At Isometric, we manufacture precise molds that achieve sub-micron accuracy. We also have injection molding machines specialized for micro-sized molding and cleanrooms (Class 10,000/ISO Class 7). By integrating mold making, molding, and assembly, we control variations and deliver high-precision molded products.

-

About Our Manufacturing Facility - Isometric

Isometric, part of the Nissha Group in the USA, has over 30 years of experience in manufacturing small and precise components for medical devices and pharmaceuticals. Location: 330 Wisconsin Drive, New Richmond, WI 54017, USA Website:

https://isomicro.com/

Isometric's Technology

Isometric’s technology specialized in micro molding builds advanced processes for mold making, molding, and assembly, enabling the delivery of high-precision micro-molded products.

-

- Precision Mold Making

- Using state-of-the-art technology and skilled technicians, we manufacture precise molds that achieve sub-micron accuracy.

-

- Material Expertise

- We possess extensive knowledge of various materials, including thermoplastic resins such as PEEK, bioresorbable materials, fluoropolymers, and silicone rubber.

-

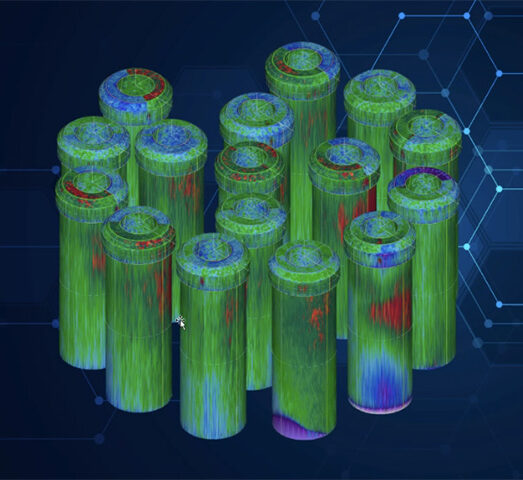

- CT Scanning

- Using photosensitive polymer resin, we produce ultra-precise micro 3D printed parts. This allows for quick and cost-effective verification of development designs, reducing time and costs to market. Additionally, we can manufacture insert molds using 3D printing.

-

- 3D Micro Printing

- Using photosensitive polymer resin, we produce ultra-precise micro 3D printed parts. This allows for quick and cost-effective verification of development designs, reducing time and costs to market. Additionally, we can manufacture insert molds using 3D printing.

-

- Micro Automated Assembly

- We assemble components with micron-level precision from molding to assembly. Utilizing various techniques such as laser welding, laser ablation, compression welding, plasma/corona treatment, UV curing, and ultrasonic welding, we perform precise assemblies.

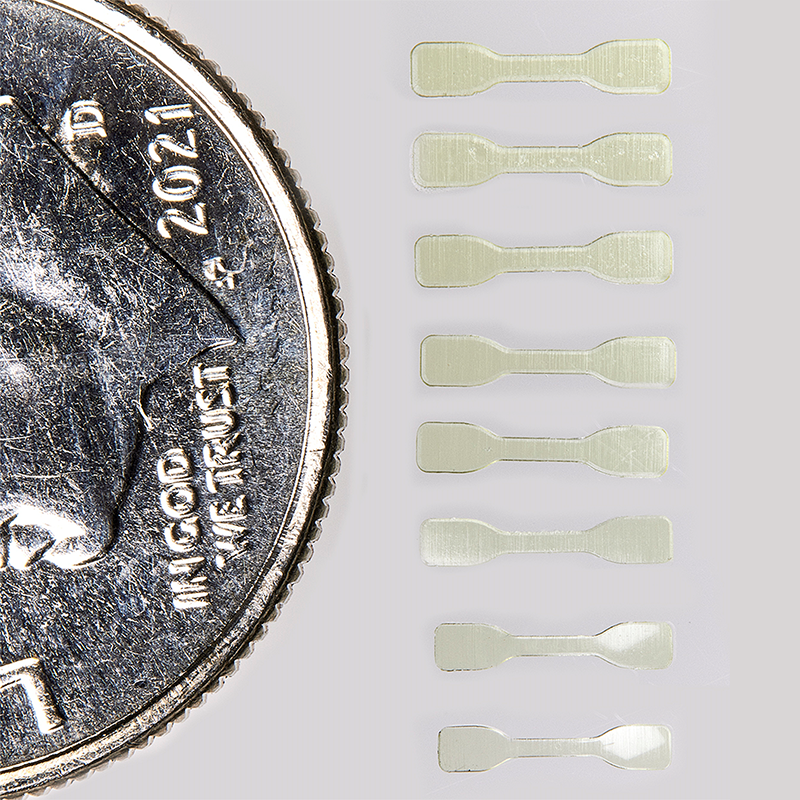

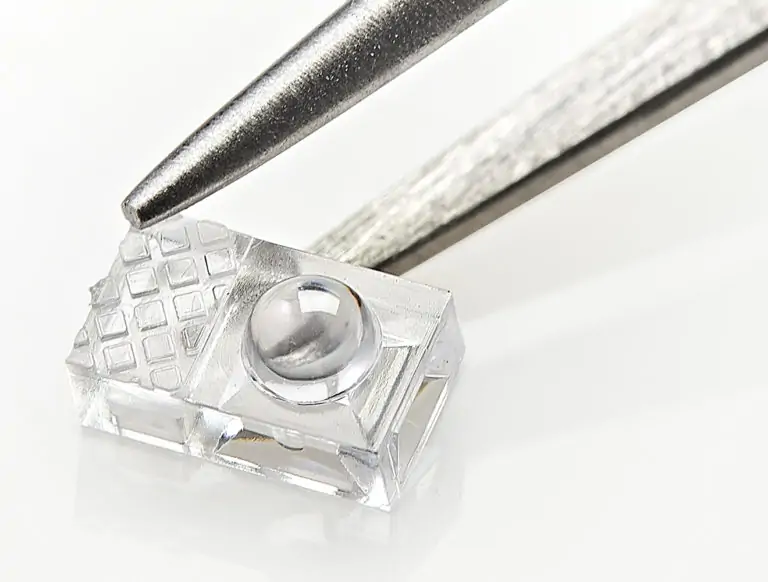

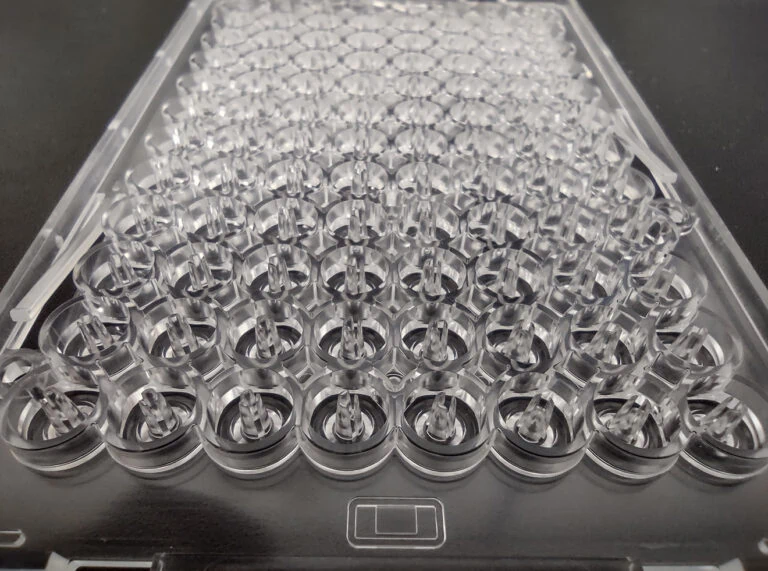

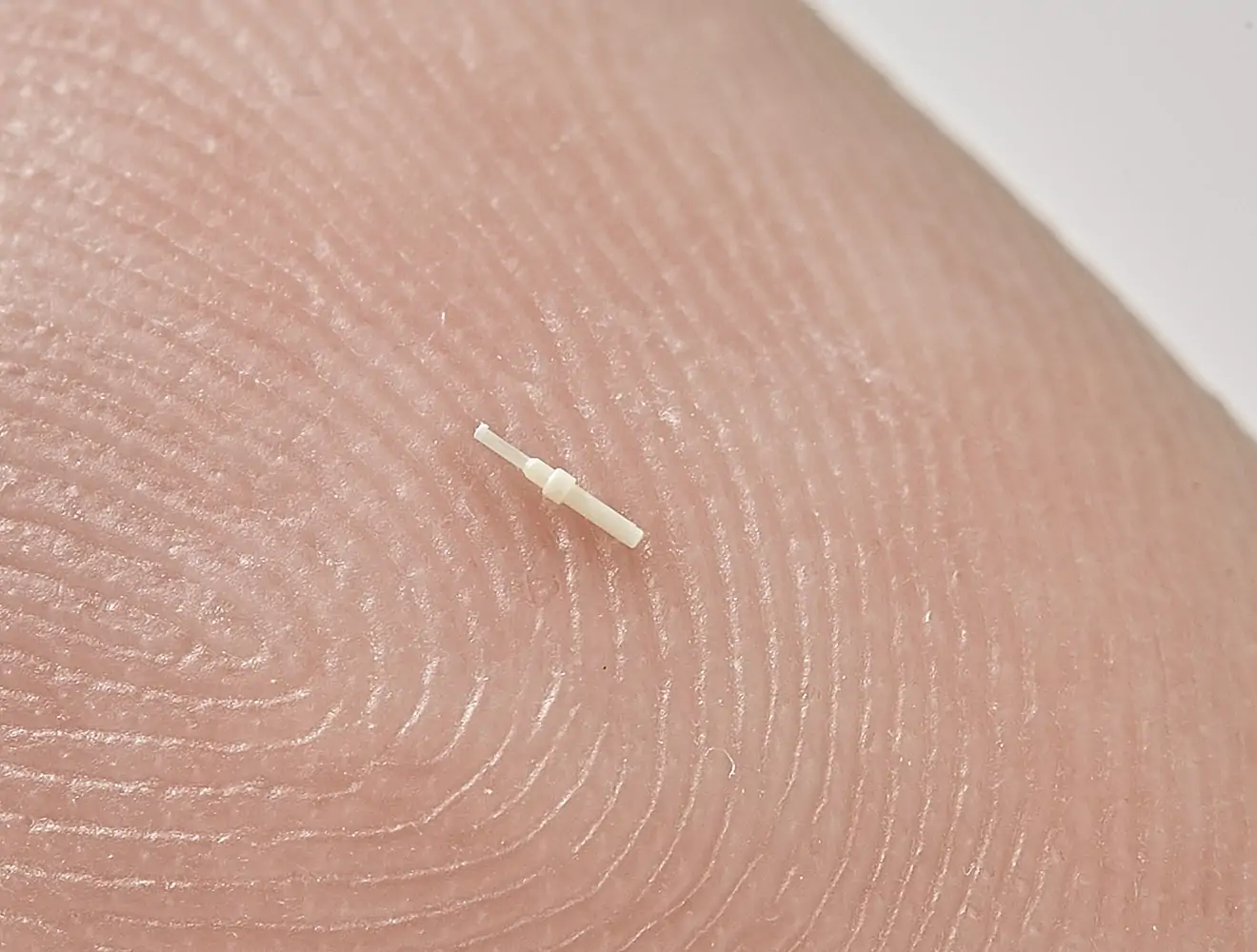

Example Parts

With over 30 years of experience and extensive material knowledge, Isometric offers a wide variety of micro parts. Here are some examples:

-

- Endoscope Tip Components

- Material: Pebax® Elastomer

- Feature: Insert molding

-

- Optical Lens Parts

- Material: Polycarbonate

- Feature: Lens functionality

-

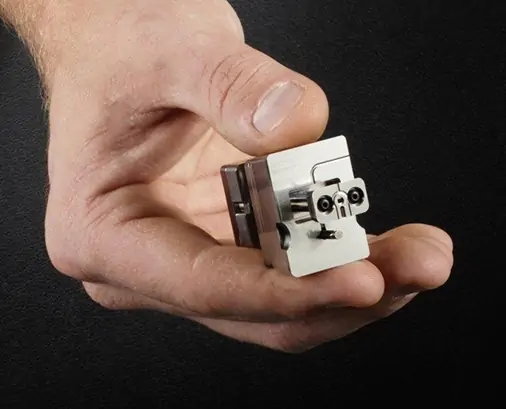

- Surgical Support Robot Parts

- Material: PEEK

- Feature: Thin-wall molding

-

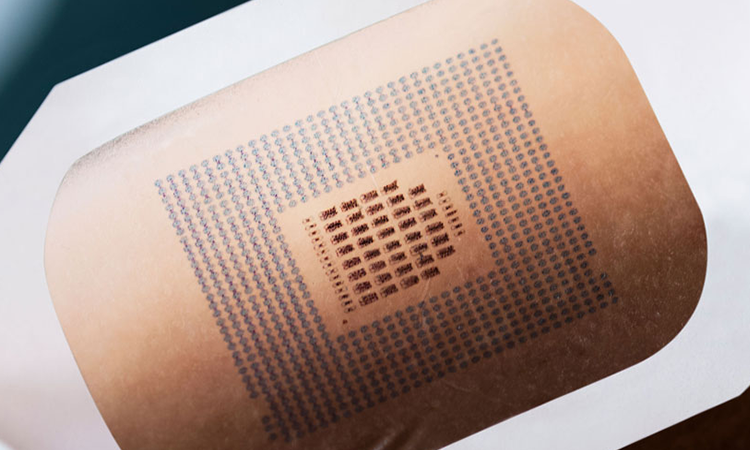

- PCR Array Plates

- Material: Polystyrene

- Feature: High precision +/- 25µm

-

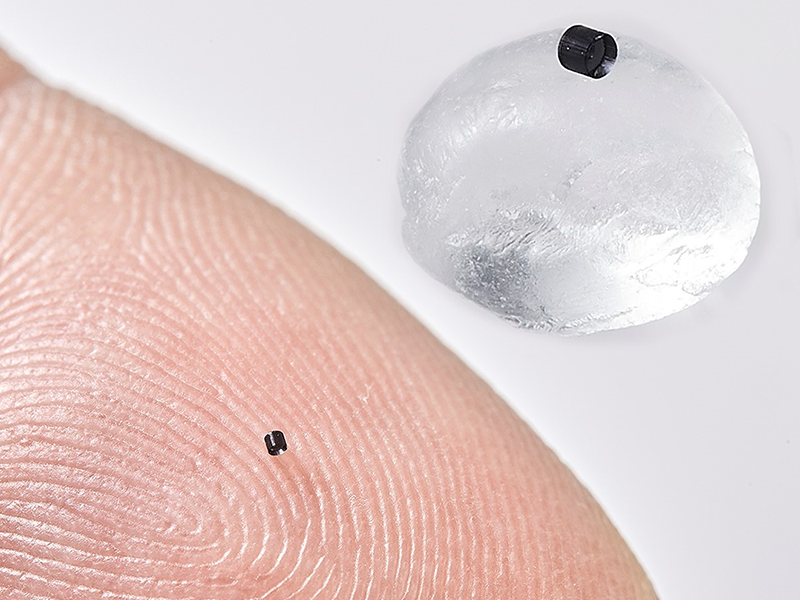

- Electronic Device Components

- Material: LCP

- Feature: Ultra-small molded parts < 90um

-

- Microfluidic Channels

- Material: LCP

- Feature: Minimum channel width 3µm