- Unique plastic molding technology with excellent designs

- Available for the incorporation of electronic components into plastic parts

NISSHA has responded to various requests of our customers using our own plastic injection molding technology.

We believe that the technology can also be used to manufacture components of medical devices.

Our plastic injection molding technology realizes aesthetically pleasing appearance and functionality.

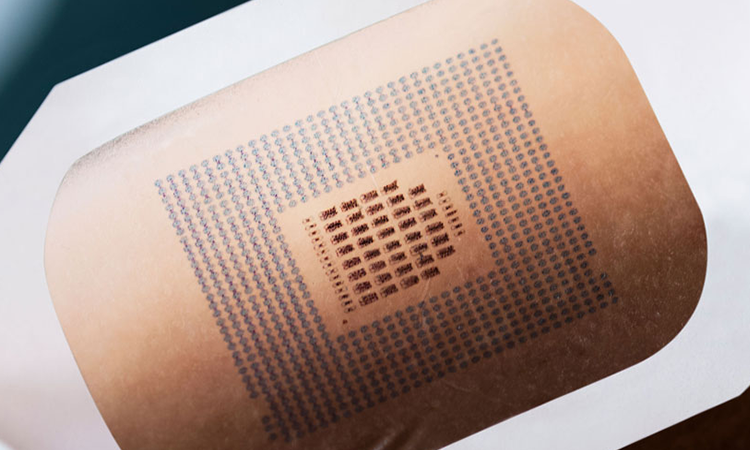

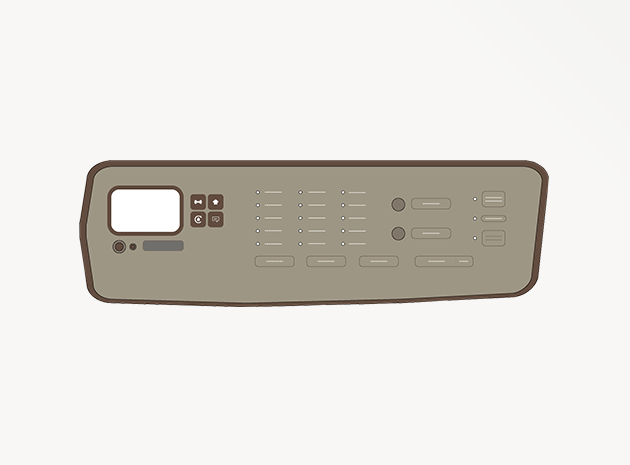

Adding variety of designs on surface parts of medical devices

IMD ( In-mold decoration ) and IML (In-mold labeling) are simultaneous injection-decoration technologies that make the parts of medical device covers brighter and discernible.

Our IMD and IML tecnology transfer a printed layer to the surface of the molded part, or insert a multi-colored film on the surface of the molded part.

Molded parts manufactured with IMD, IML can be formed into parts of covers with an aesthetically pleasing appearance.

-

Multi-color printing

Since multicolored films are used, the buttons can be color-coded by function, and graphical pictorial patterns can be added in the spaces of the panel.

-

Transparent window

By inserting a picture layer with a window part on the surface of the transparent resin molded parts, a clear window is created without using 2shot molding technology, while reducing the number of molded parts around the display.

-

Light transmission design (dead front)

Light transmission design that characters and icons emerge from beneath various designs (e.g., metallic, woody, fabric) .

Functional value added on surface of molding parts

Functional coating film can be added to the surface of the IMD- and IML-manufactured molded parts. Various functional coat layers are available to respond to your requests, e.g., improvement of durability, addition of texture, and an antibacterial effect.

-

Hard coat

A hard coat film that can be shaped to fit a three-dimensional surface.

Has been used on the interior panels of automobiles, etc., and has shown superior abrasion resistance. -

Slip resistance

Coating film with a soft touch like rubber.

Can be used to prevent slipping of the grip. -

Antibacterial coating

It is possible to create a top layer with antibacterial function certified by SIAA.

JIS Z 2801 antibacterial test showed an antibacterial activity value of 5.3 (E. coli, S. aureus)

What are IMD and IML ?

IMD and IML of Nissha are technologies to insert a decorative film in a die and

decorate the surface of a molded part at the same time as injection molding.

-

IMD(In-mold Decoration)

IMD is a technology that transfers only the printed layer on decorative film to the surface of molded part.

This technology can implement molding and decoration in the same process. -

IML(In-mold Labeling)

IML is a technology to insert a decorated film on the surface of a molded part.

This technology can also insert a film over a molded part with a deep shape.

- *IMD and IML are registered trademarks of NISSHA Co., Ltd.

- *IMD is the abbreviation of “In-mold Decoration.” This is a term of our company that was named from the technology of simultaneous decoration and molding using transfer foil in a die of injection molding. IML is an abbreviation of “In-mold Labeling.”

-

-

- Resin type

- PS, PP, ABS, acrylic, PC, etc.

General thermoplastic resins are acceptable.

We ask customers to request resin materials and examine the optimal processing conditions.

-

-

-

- Vacuum molding of film

- In addition to injection molding, it can also be applied to vacuum molding of plastic films.

We have experience with vacuum molding of plastic films such as acrylic, ABS, and PP.

-

Examples

Feel free to ask us about medical injection molding.

製造拠点Production sites

アジアAsia

成形工場Molding site

- 中国・昆山(Kunshan)Kunshan, China

- 中国・広州(Guangzhou)Guangzhou, China

- マレーシアMalaysia

印刷工場Printing site

- 日本・甲賀Koka, Japan

北米North America

成形工場Molding site

- ミシガン州・VicksburgVicksburg (MI), USA

- メキシコ・San Luis PotosiSan Luis Potosi, Mexico